woodbloke

Established Member

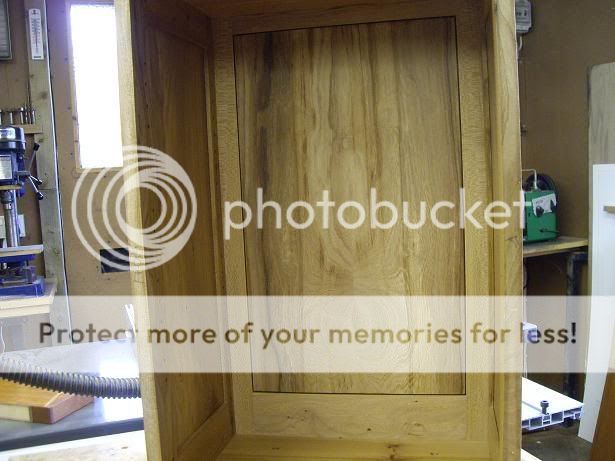

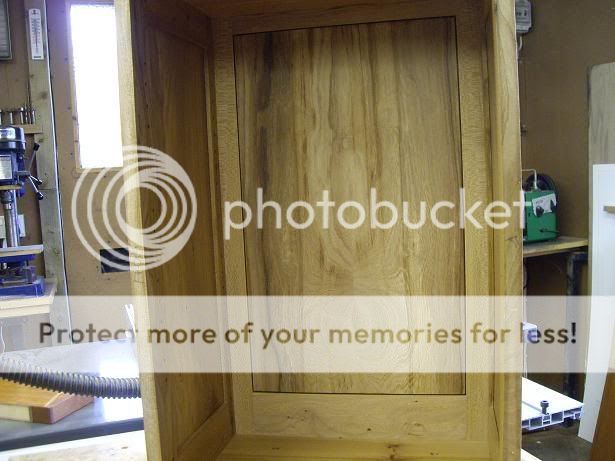

I managed to fit the back panel as shown in the pic:

into the rebate in the main carcase. The panel surface is flush with the frame (more by accident than design) so I've been able to sand both together before fitting... the panel in the pic has been roughly sanded with no finish yet applied. The panel itself is 8mm thick and has been bookmatched to form the quite pleasant pattern. I've had some problems :x with this one as a quick perusal of the Blokeblog will indicate, but I think it's all going to turn out good in the end Finish will be a couple of coats of matt Osmo-PolyX with some wax over the top, with more sanding yet to do tomorrow...will post some more pics when finally polished and installed - Rob

Finish will be a couple of coats of matt Osmo-PolyX with some wax over the top, with more sanding yet to do tomorrow...will post some more pics when finally polished and installed - Rob

into the rebate in the main carcase. The panel surface is flush with the frame (more by accident than design) so I've been able to sand both together before fitting... the panel in the pic has been roughly sanded with no finish yet applied. The panel itself is 8mm thick and has been bookmatched to form the quite pleasant pattern. I've had some problems :x with this one as a quick perusal of the Blokeblog will indicate, but I think it's all going to turn out good in the end