jimi43

Established Member

Ok...since there are those here with eyes approaching those of an eagle...(yes Andy!)....I thought I had better show you all what I have been up to lately.

Fuelled by a fine Japanese iron from our dear friend Pekka and his "accidental" hoard of planes...and selecting a likely candidate...I set about deciding what to do with it.

I probably will eventually make a kanna (Japanese Plane)....but since I like to push the boundaries a bit..I thought I would see how it would work the other way up...in a Western smoother. So...all I needed was something wooden to hold it...and that was what this was for....

No...it's not a potential group of woodie wedges Andy...as you now know. :wink: ...but this is where it is going:

This is where things get a little confusing..push or pull?

Later on that one! :mrgreen:

Ok Rob (Platt)....you are either a great expert on wood or was it just luck but yes...it's partly Australian but only in wood species...

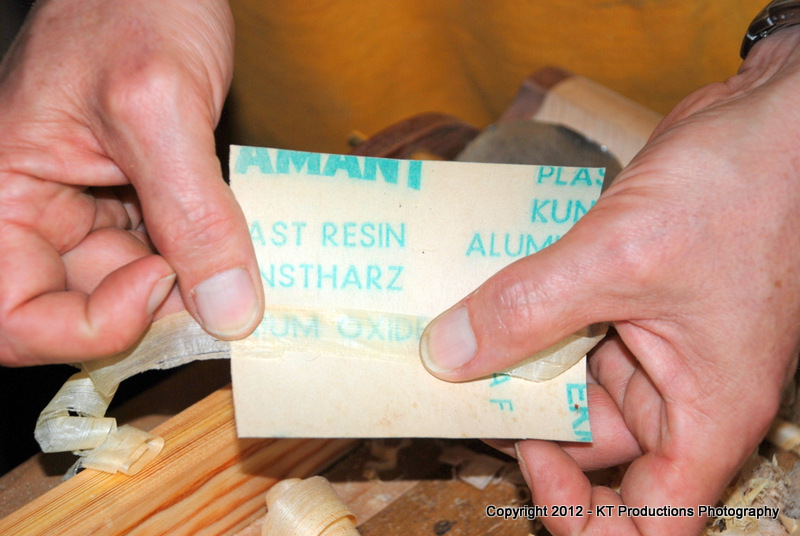

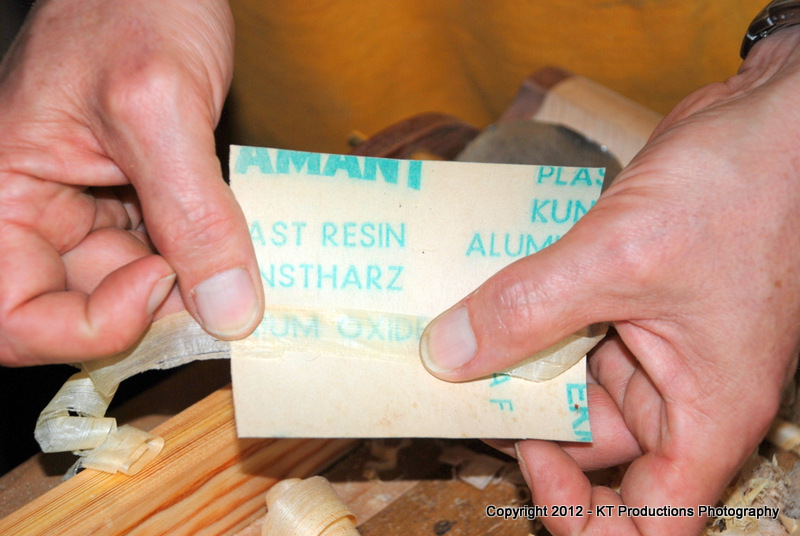

...Western Australian Jarrah....the only bit I have now...and from a sleeper (as can be seen!)....makes the sides...

....with a bit of shaping....

...and put together to check the layout...

A brass rod was then used to form a flat (yes I know it's round) cross wedge bridge....

I want to be able to set the mouth...so just for now...the front moves back and forward...

Inside the block are two rebates...one on each side...in which a lignum vitae tongue is glued. This runs in rebates in both of the sides and is locked in place by bolts into captive nuts...

This results in a very fine mouth for the finest finish....

At this point...a major Eureka Moment... :idea: occurred quite by accident.

The round bar being half transformed into a flat...and being impatient to see how it formed...I left the other side rounded...

At this point I tried the iron for fit...and then couldn't get it out!!! HEEEELLLLP!

The reason for this was that the bar had rolled round and locked the iron against the bed...a cam action!

I swore...a lot! And then it hit me...if I couldn't get it out..then it wouldn't come out...and once set would stay there!

And so the CAMWEDGE was born!! 8)

I also found (obviously! DOH!) that tapping the iron in hard..released it!

So...a wedged plane iron...without a wedge! 8)

Right then...how does it perform....first FORWARD....

....and Alfie confirmed....

....it WORKS!

...and BACKWARDS....

...so when Douglas brought round my Moxon vise to test...he also tested the camwedge plane...

...and also backwards too!

...even with a coarse set!

I know it probably won't win any beauty contests just yet (but watch this space)....but now I have proved it works...more refinements will be made...and further tests done...but for the first outing...it appears to fly!

Doesn't it Alfie,,,,,,,

Yes Dad...you're MAD Dad...totally BONKERS Dad.....!

But fun!

Cheers guys and gals!

Jim

Fuelled by a fine Japanese iron from our dear friend Pekka and his "accidental" hoard of planes...and selecting a likely candidate...I set about deciding what to do with it.

I probably will eventually make a kanna (Japanese Plane)....but since I like to push the boundaries a bit..I thought I would see how it would work the other way up...in a Western smoother. So...all I needed was something wooden to hold it...and that was what this was for....

No...it's not a potential group of woodie wedges Andy...as you now know. :wink: ...but this is where it is going:

This is where things get a little confusing..push or pull?

Later on that one! :mrgreen:

Ok Rob (Platt)....you are either a great expert on wood or was it just luck but yes...it's partly Australian but only in wood species...

...Western Australian Jarrah....the only bit I have now...and from a sleeper (as can be seen!)....makes the sides...

....with a bit of shaping....

...and put together to check the layout...

A brass rod was then used to form a flat (yes I know it's round) cross wedge bridge....

I want to be able to set the mouth...so just for now...the front moves back and forward...

Inside the block are two rebates...one on each side...in which a lignum vitae tongue is glued. This runs in rebates in both of the sides and is locked in place by bolts into captive nuts...

This results in a very fine mouth for the finest finish....

At this point...a major Eureka Moment... :idea: occurred quite by accident.

The round bar being half transformed into a flat...and being impatient to see how it formed...I left the other side rounded...

At this point I tried the iron for fit...and then couldn't get it out!!! HEEEELLLLP!

The reason for this was that the bar had rolled round and locked the iron against the bed...a cam action!

I swore...a lot! And then it hit me...if I couldn't get it out..then it wouldn't come out...and once set would stay there!

And so the CAMWEDGE was born!! 8)

I also found (obviously! DOH!) that tapping the iron in hard..released it!

So...a wedged plane iron...without a wedge! 8)

Right then...how does it perform....first FORWARD....

....and Alfie confirmed....

....it WORKS!

...and BACKWARDS....

...so when Douglas brought round my Moxon vise to test...he also tested the camwedge plane...

...and also backwards too!

...even with a coarse set!

I know it probably won't win any beauty contests just yet (but watch this space)....but now I have proved it works...more refinements will be made...and further tests done...but for the first outing...it appears to fly!

Doesn't it Alfie,,,,,,,

Yes Dad...you're MAD Dad...totally BONKERS Dad.....!

But fun!

Cheers guys and gals!

Jim