devonwoody

Established Member

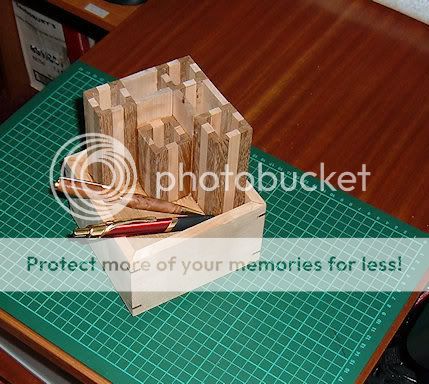

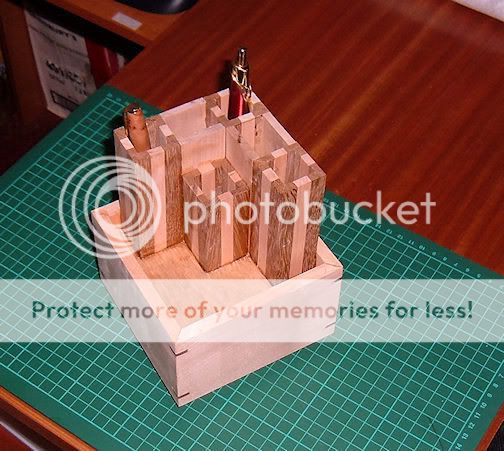

Started my new ? I don't think it would be classed as a box.

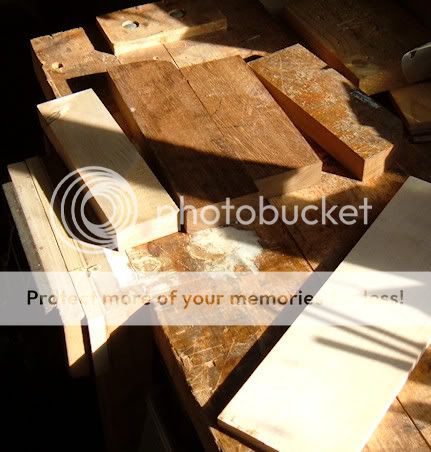

Went through the offcuts and found this piece of Br.Mahogany 1mtr by 100mm by 5 mm thick. It has been lying around for perhaps 3 years, and was the waste piece from a 25mm thick board off the bandsaw when doing that blade review for you know who.

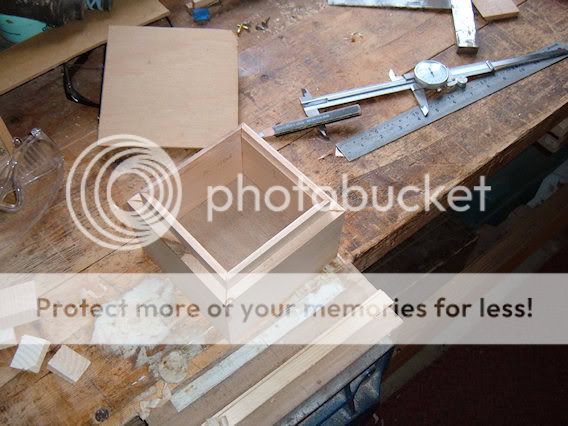

So put it through the table saw to reduce width and recut twice at the same fence setting so that both pieces were the same width.

Held it down with this. (its only 5mm thick)

Then put it through the tablesaw again but with the blade set to 45% and held down with this temporary clamp and block.

Hand cut to 100mm lengths and set up ready for gluing. I have found it pays to hold the masking tape down with a small piece of masking tape each end whilst preparing to glue and fold up to stop the tape winding back on its self.

First part glued up and three more to go.

Went through the offcuts and found this piece of Br.Mahogany 1mtr by 100mm by 5 mm thick. It has been lying around for perhaps 3 years, and was the waste piece from a 25mm thick board off the bandsaw when doing that blade review for you know who.

So put it through the table saw to reduce width and recut twice at the same fence setting so that both pieces were the same width.

Held it down with this. (its only 5mm thick)

Then put it through the tablesaw again but with the blade set to 45% and held down with this temporary clamp and block.

Hand cut to 100mm lengths and set up ready for gluing. I have found it pays to hold the masking tape down with a small piece of masking tape each end whilst preparing to glue and fold up to stop the tape winding back on its self.

First part glued up and three more to go.