^^^ Wot Eee said (as usual!).

Slow speed, water lubrication (if you can contrive that) and/or dust clearance, probably quite a lot of "remove-drill... clean... continue". If dry, you need to have a vacuum running to remove dust as fast as possible and keep the hole as clean as possible.

I'd do the pilot hole first - it will give you a feel for the material and a chance to correct any alignment before cutting the perimeter of the hole. Drill through electrical or masking tape to get the pilot started (stops skidding). For porcelain glazed tiles I also use a big masonry pin to indent the surface, as masonry bits have a blunt point and/or an offset centre - infuriating if you want accuracy. You should be OK with just tape, but if not there are cheap diamond burr sets available that would do the same thing. If you use carbide for the pilot hole, that drill WILL heat up. I can't be the only person to find I was trying to drill using a bit with no carbide tip on it any longer! Slow speed, NO hammer action, etc. You just have to be patient

The big issue with diamond hole saws in my experience is clogging and then jamming. I have a really large one for doing extractor fan ducting, and you have to be rather careful driving it because it will jam easily. I've been very grateful for the slipping clutch on my Makita SDS (and I think I knackered it using the diamond core drill!).

I've had good results with the Marcrist brand. The smallest I have, however, is 40mm, which gets used for bath and basin waste pipes, and through building materials (usually not granite! It's limestone mostly round here, which is softer). It would be no good if the hole was on show though, as it's way too large to look neat. Smaller ones are available. But there is a trade off between snugness and difficulty of alignment - probably worth allowing 5mm on the diameter as a compromise.

At a guess (and it IS a guess) anything suitable for porcelain ought to do granite too - after all diamond tooling is what's used in the factory to cut and polish. That said, the size of the diamond particles probably matters - tooling for brick and blockwork is possibly too aggressive for granite.

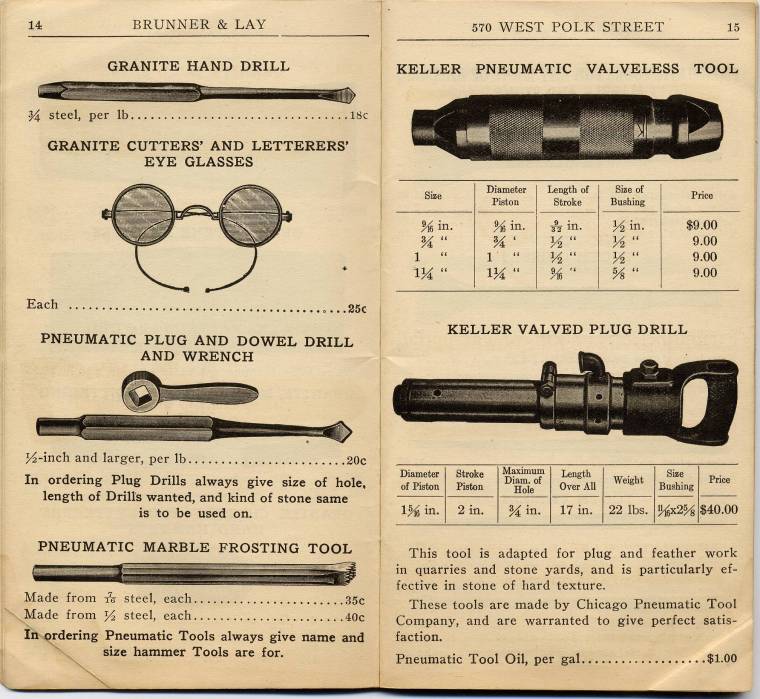

By the way, it's not impossible, by any means. This is how it used to be done by hand (top left) - thump, rotate, repeat: