Thanks for all your replies so far, chaps. I didn’t expect such helpful and insightful responses to what I thought might be taken as a daft thread on my part.

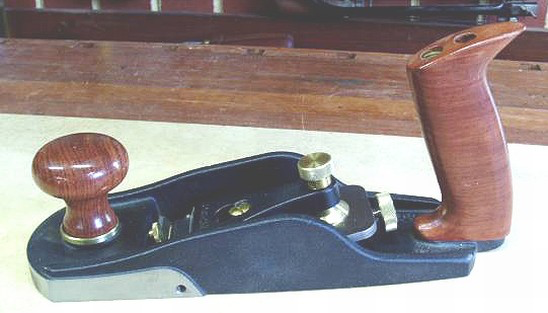

Derek, that’s a beautiful job you’ve done on the Veritas. The tote is a massive upgrade in looks and, I’m sure, in performance, too.

One thing I agree about is that quality matters. In my situation, it seems all my options are more than adequate to do what I want, so there’s no bad decision to make; it just comes down to the other factors mentioned.

Tom, I agree I shouldn’t be expecting LN or Clifton fit and finish from a bandsaw. I know that would probably be impossible and not desirable or remotely affordable. I see hand tools and machines differently on this scale of looks.

I seem to have different standards for different categories of tools and machines. Human-powered hand tools are my thing; I like premium for those. Perhaps because they’re more intimate and integral to how we work with our hands, the more premium, the more satisfying to use and own. That said, I have a number of vintage Stanley's that I would put in that category, especially in comparison to modern Stanley planes.

Electron-powered hand tools I don’t seem to care as much. I have so few of them and use them so infrequently that I can accept the garish green and mid-range quality of my few Ryobi One+ drills/sander. They mostly live in a box out of sight until I need to erect or dismantle a piece of IKEA pretend furniture.

Machines then are another category. Build quality, fit and finish seem to contribute more to performance here. I’m not just talking paint jobs, though that somewhat matters. Many of you are spot on with what I’m feeling: good ‘looks’ is perhaps just the culmination of many elements of sound engineering and robust materials. I.e. not too many plastic fixtures, smooth castings, adequately strong materials where necessary etc.