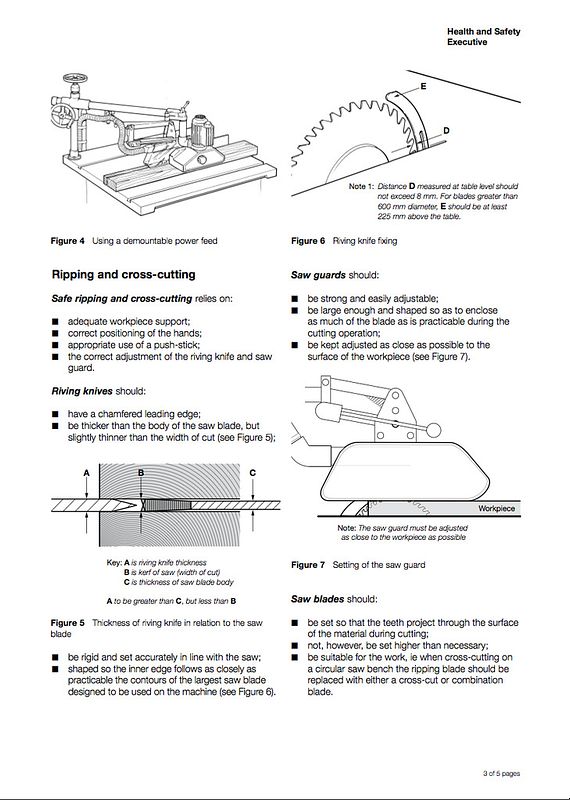

I would really welcome knowing what the correct thickness of a circular saw riving knife should be. I thought I knew. However, the other day I baught a new circular saw blade and was chatting to the chap who happened to have been in the Royal Navy and a time served wood worker / machine setter. He was informing me that he had been taught that the riving knife should ideally be a 0.1~0.2mm larger on either side of the kerf cut by the blade. So, overall 0.2 to 0.4 larger than the saw kerf. The reason for this was not only to ensure that the stuff did not close up behind the blade causing a kick back, but to ensure that the back edge of the blade as it rises out of the table does not cut the stuff as well as the leading front edge. This would increase the life of the blade and improve the cut edge tremendously.

Well, this was rather contrary to what I had believed, which was that the riving knife should be just slightly thinner than the kerf cut by the blade. Clearly if the saw has a parallel fence such as those favoured by the Americans I can see that a wider riving knife is going to cause a lot of problems. However, my ripping saw which is an old Sedgwick has a short fence so this would not be an issue.

Well, this was rather contrary to what I had believed, which was that the riving knife should be just slightly thinner than the kerf cut by the blade. Clearly if the saw has a parallel fence such as those favoured by the Americans I can see that a wider riving knife is going to cause a lot of problems. However, my ripping saw which is an old Sedgwick has a short fence so this would not be an issue.