Hi all

I'm really excited about making a this chair.

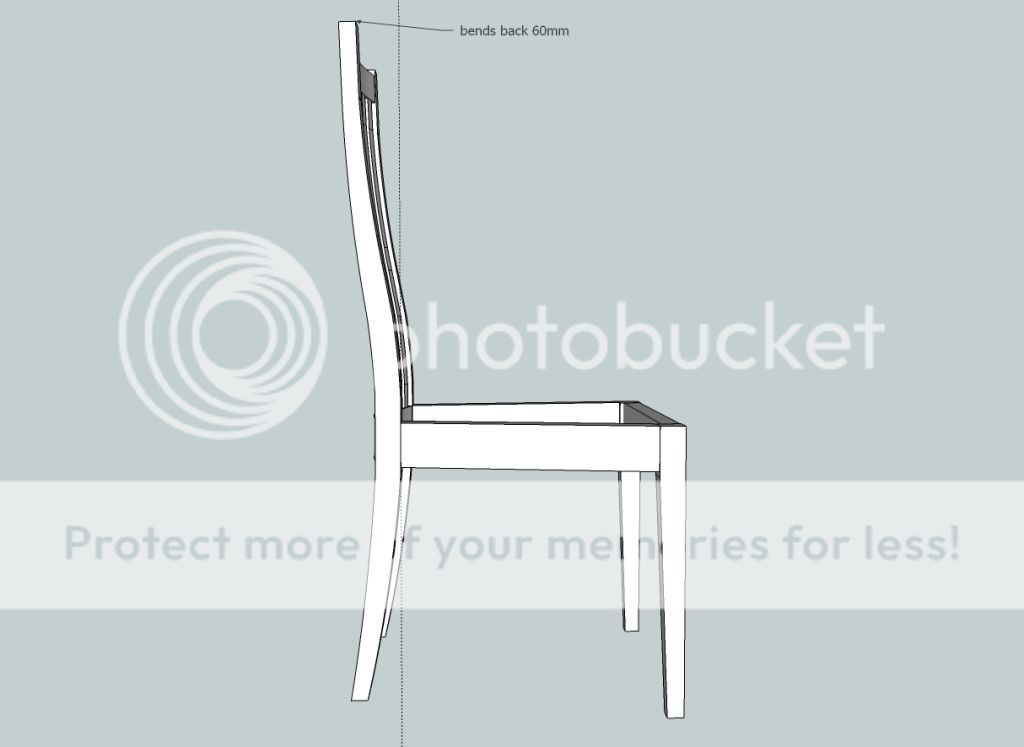

http://s1082.photobucket.com/albums/j37 ... chair6.jpg

As you can see the back leg is curved. At its widest point (at seat level) it is 38mm x 38mm and it tapers 2 ways at the bottom of the leg to 25mm by 25mm and tapers one way at the top of the leg to 38mm x 25mm. The top of the leg is bent back 60mm.

Because of the tapers I don't want to laminate it as I will be cutting through the veneers.

So I either cut it from a pice of 4x2 and hope the short grain doesn't break when I sit on it or I do the job properly and steam bend it. If I steam bend it I'd use oversize timber say 50mm x 50mm and then use a template to router both legs to the exact dimensions I need.

I have no steam bending experience but have read quite a lot about it.

My timber choices are either Euro Oak, US Ash or US Black Walnut as I have some of these in the garage.

Thing is I've read that bending Kiln dried is a nightmare because the lignum in the wood gets set in the kiln.

Please offer me some thoughts to accelerate my learning curve.

Would Ash be a better choice if I'm using kiln dried?

Can I use Kiln dried if I stick the timber in the bath for a week or so prior to steaming?

Should I be getting some air dried to use instead - just for the back legs?

Should I forget about bending and just band saw it from a piece of 4x2 (in the Jeff Miller chair book I have this is what he does)

Thanks in advance, Andrew

I'm really excited about making a this chair.

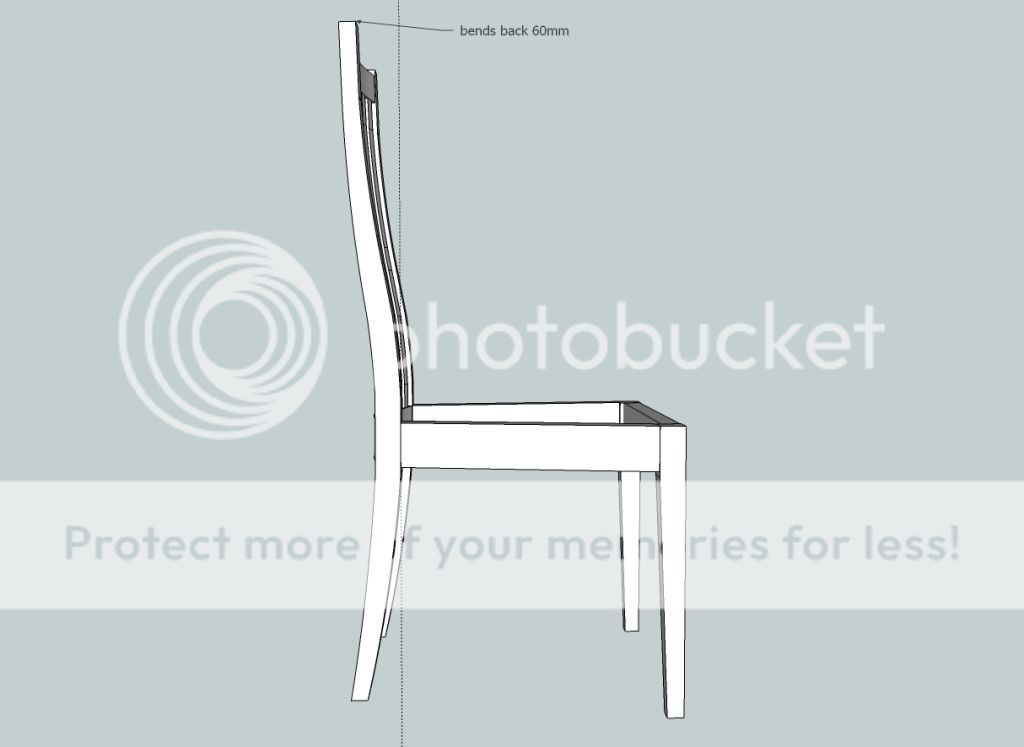

http://s1082.photobucket.com/albums/j37 ... chair6.jpg

As you can see the back leg is curved. At its widest point (at seat level) it is 38mm x 38mm and it tapers 2 ways at the bottom of the leg to 25mm by 25mm and tapers one way at the top of the leg to 38mm x 25mm. The top of the leg is bent back 60mm.

Because of the tapers I don't want to laminate it as I will be cutting through the veneers.

So I either cut it from a pice of 4x2 and hope the short grain doesn't break when I sit on it or I do the job properly and steam bend it. If I steam bend it I'd use oversize timber say 50mm x 50mm and then use a template to router both legs to the exact dimensions I need.

I have no steam bending experience but have read quite a lot about it.

My timber choices are either Euro Oak, US Ash or US Black Walnut as I have some of these in the garage.

Thing is I've read that bending Kiln dried is a nightmare because the lignum in the wood gets set in the kiln.

Please offer me some thoughts to accelerate my learning curve.

Would Ash be a better choice if I'm using kiln dried?

Can I use Kiln dried if I stick the timber in the bath for a week or so prior to steaming?

Should I be getting some air dried to use instead - just for the back legs?

Should I forget about bending and just band saw it from a piece of 4x2 (in the Jeff Miller chair book I have this is what he does)

Thanks in advance, Andrew