MikeG.

Established Member

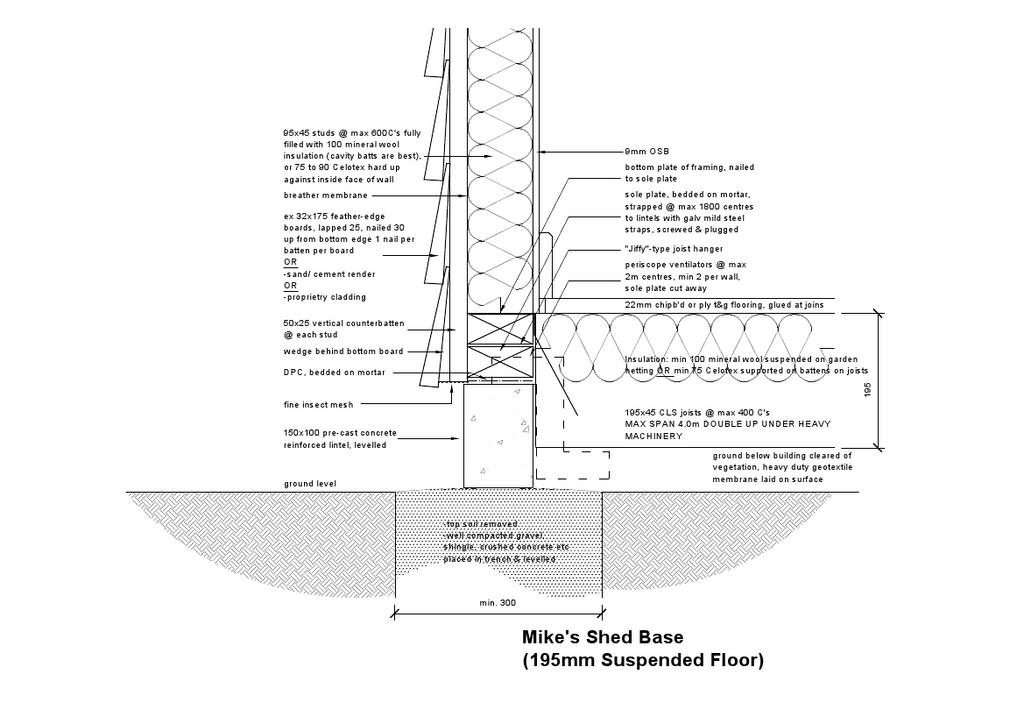

There have been a number of enquiries lately from people who want to build a shed, but are worried about building a concrete base and laying a brick plinth. Whilst that remains the best way by far, I thought I would put together a thread for people who wanted a concrete-free alternative, without bricks. Please note that you should not attempt this technique for large buildings (say 20sq m or more), nor for buildings which need to show compliance with Building Regulations. If you plan on using a large lathe regularly I would also avoid a timber suspended floor, and would refer you tomy original thread on workshop building.

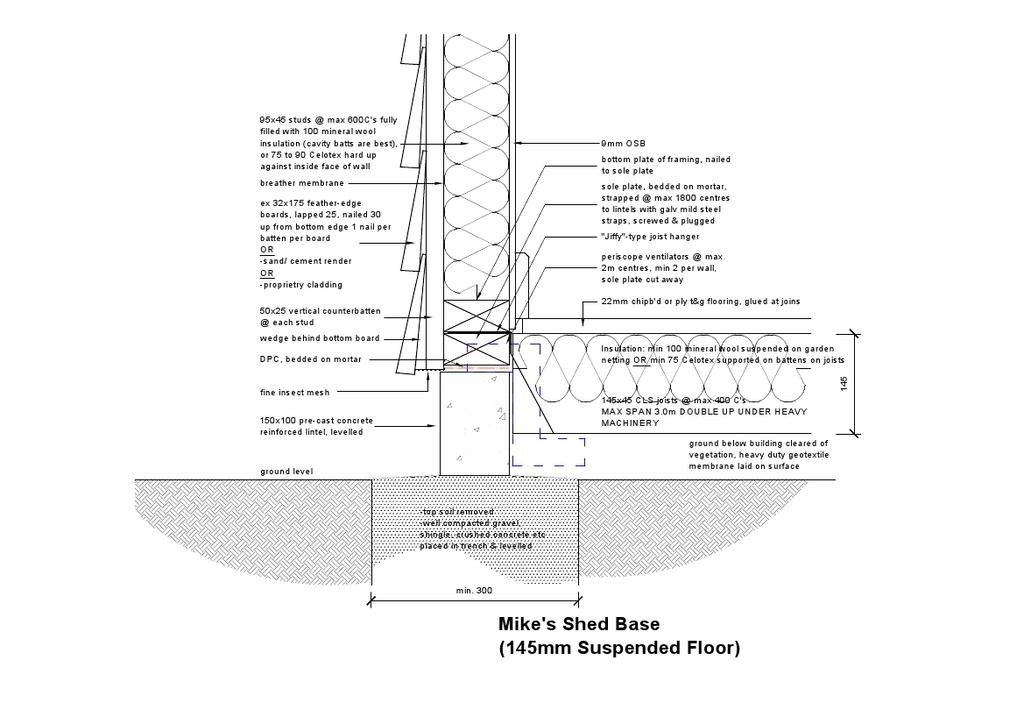

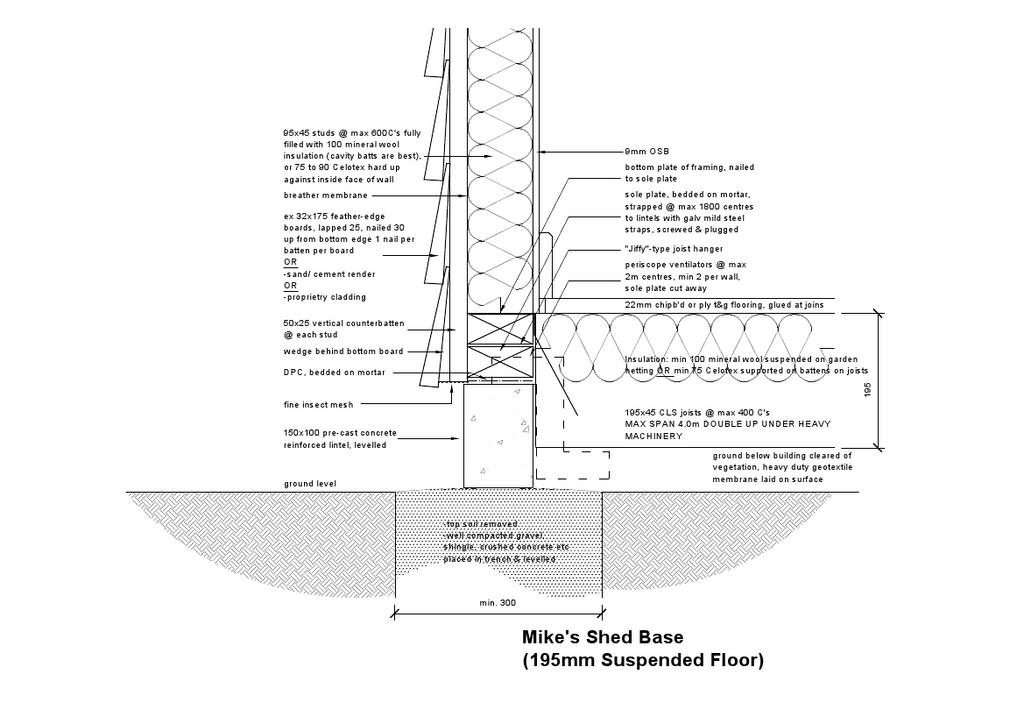

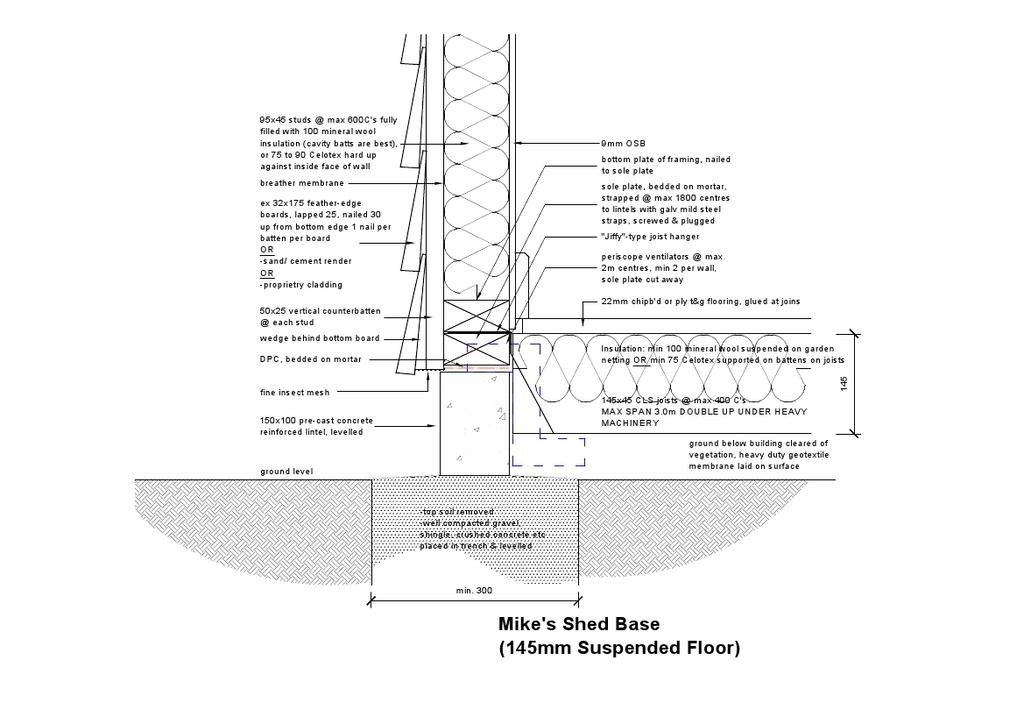

The principle of this alternative construction is to use readily available and cheap concrete lintels (from any Builders Merchant) to raise the timber the necessary 150mm above the ground. There is a minimum of digging, but topsoil must be removed around the perimeter, as well as all vegetation.

I show 2 alternatives, with the difference being the span of the floor.

Here are the drawings:

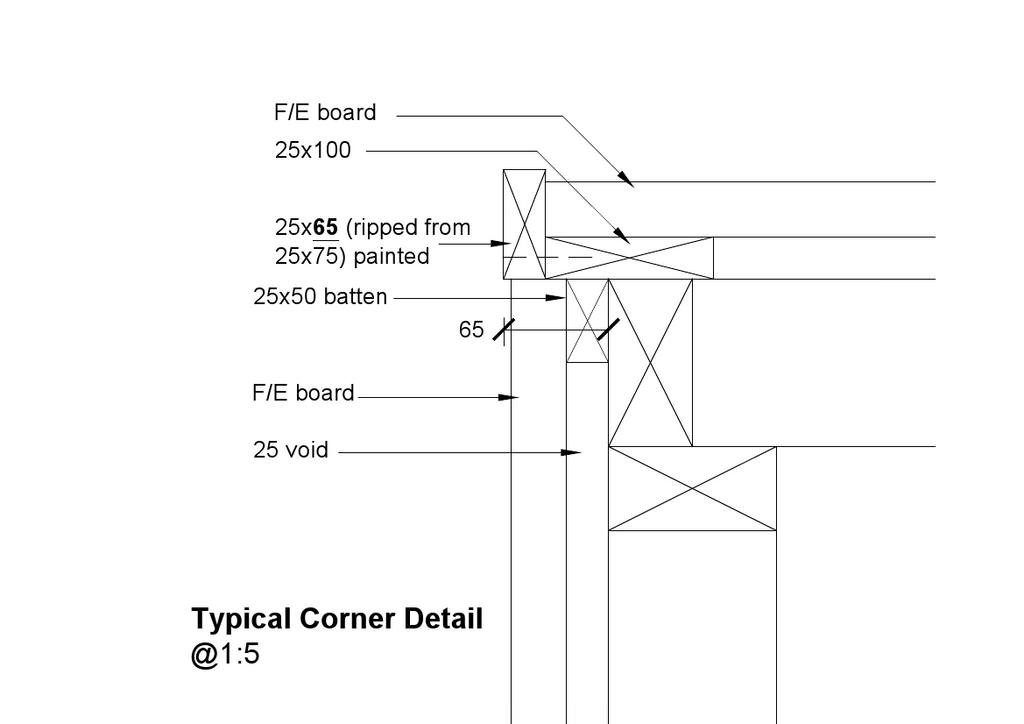

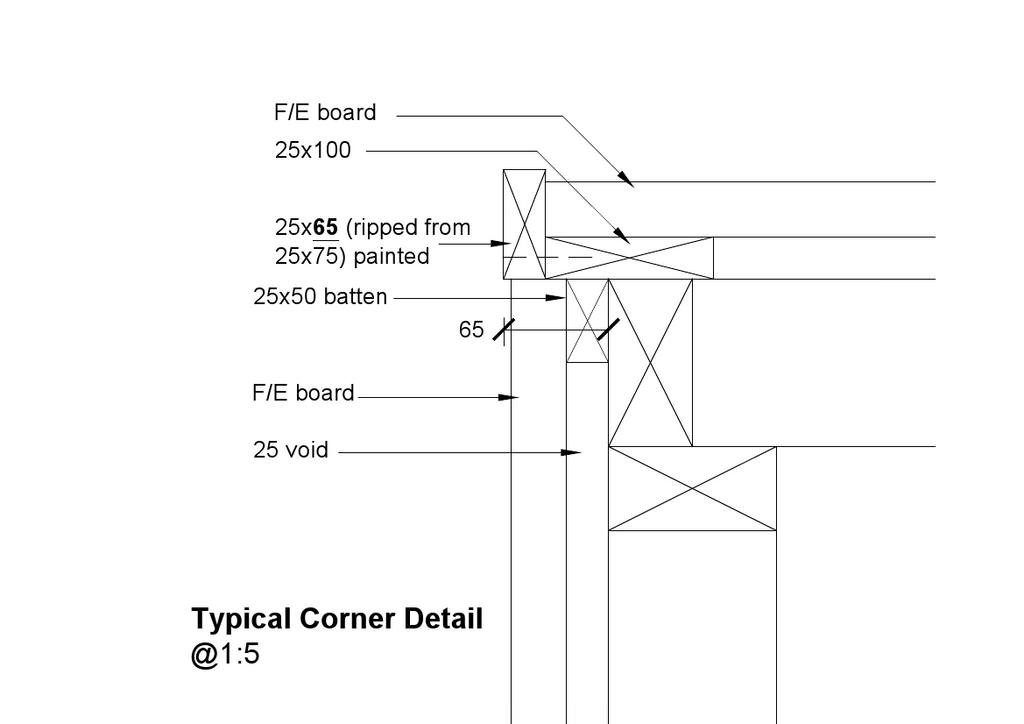

Here is my typical corner detail for feather-edge boarding (this is a Plan Section):

Everything above the floor remains as per my original thread, and of course there are a myriad alternatives for the roof.

Now, I really should get on with some work!

The principle of this alternative construction is to use readily available and cheap concrete lintels (from any Builders Merchant) to raise the timber the necessary 150mm above the ground. There is a minimum of digging, but topsoil must be removed around the perimeter, as well as all vegetation.

I show 2 alternatives, with the difference being the span of the floor.

Here are the drawings:

Here is my typical corner detail for feather-edge boarding (this is a Plan Section):

Everything above the floor remains as per my original thread, and of course there are a myriad alternatives for the roof.

Now, I really should get on with some work!