Craigus

Established Member

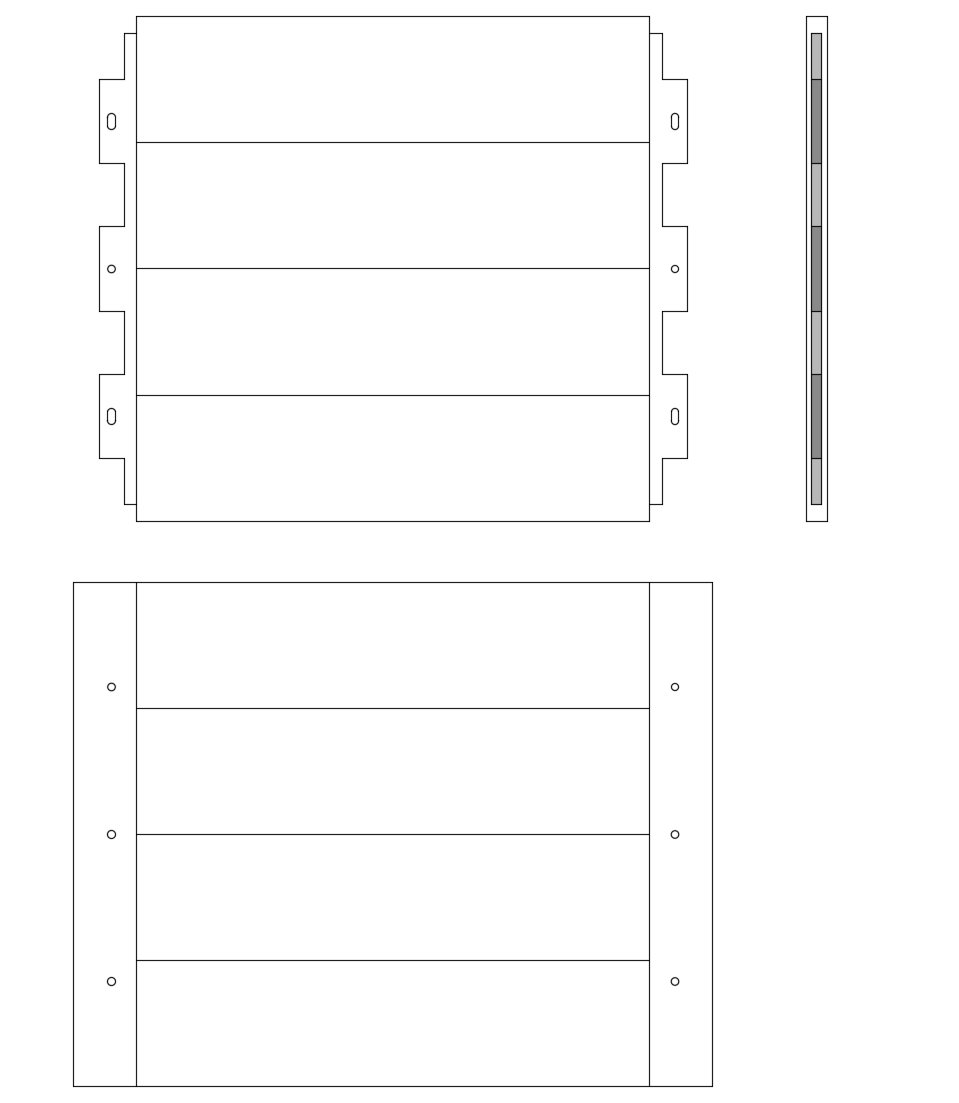

I'm putting together a Walnut table top for a small table we have, the top dims are 600 wide x 760 long. I'm not overly concerned about the wood movement in a relatively small piece, the breadboards are for the aesthetic as much as anything and to help cover the slightly untidy end joins where the boards aren't jointed perfectly.

I've not tackled anything like this before, I've read a bit about breadboard ends and how to do them properly, gluing only the center tenon etc, but does anyone have any general practical advice? It's in 22mm Walnut, so all the tenons will be quite thin.

Also, any tips for finishing the Walnut to bring the best out of the grain/colour and give it some decent protection? I'm thinking a few coats of Danish oil and a lacquer over that.

I've not tackled anything like this before, I've read a bit about breadboard ends and how to do them properly, gluing only the center tenon etc, but does anyone have any general practical advice? It's in 22mm Walnut, so all the tenons will be quite thin.

Also, any tips for finishing the Walnut to bring the best out of the grain/colour and give it some decent protection? I'm thinking a few coats of Danish oil and a lacquer over that.