adzeman

Established Member

We have had some fine weather over the past week and there are a number of jobs which were required to be started or completed. At the top of the list is to replace the roof to the workshop, damaged by the wet heavy snow earlier in the year. I am blaming the snow but it could have been me! The roof is corrugated bitumen and at the eaves prior to insulating between the sheets and the purlins I foamed the corrugation gaps to form a seal. These are rigid with no flexibility at the eves. I should have done the gaps at the purlins so, when it snowed the sheets flexed and twisted not springing back. Consequently I now have a roof that is as watertight as a colander letting in water at the lower end where my machines are placed. Because I had insulated the roof space I was unaware of the fault until we had the first heavy downpour and one bay of insulation was on the floor in a soggy mess. Fortunately it was in a spot where there was no kit or electrics giving me time to move everything into the garage.

As this section of the Forum is called “projects and mistakes” and I have

Made a few, mistakes in particular, I thought it would also give an opportunity show my home workshop and progress in renewing the roof and………….

Friends and relations in the North are interested and this is a good way of letting them know.

I have been in this property for two years now and the shed (workshop) was here at the bottom of the garden.

The shed was covered with rampant clematis, honey suckle and a viscous berberis. Some was growing inside the shed through the corrugations and gaps in the cladding. The door being difficult to open and close so, a pruning, repair job was in order. Fascias erected, trellising to tie the plants back and what I think are called Brea Solais fixed over the doors and windows.

Now the problem...

A Leaking Roof

This is a view on the under side showing a joint, 50mm from the purlin, a 70mm x 50mm timber laid on the flat.

You will observe some foam filler at the eaves which I used instead of the proprietary PVC strip filler which at a £1.00 is more expensive than a £5.00 can of foam. How much this has contributed to my problem not sure. The foam sets rigid, the strip foam filler is flexible and would possibly have sprung back when the snow melted. Also thought that when the foam continued expanding when setting would push the sheets upwards, but it didn’t. Does keep the insect out though and the spiders in, who are reduced in numbers and very thin.

View to the other Truss where there is also a sheet edge joint. You can see daylight here which did not come out on the photo.

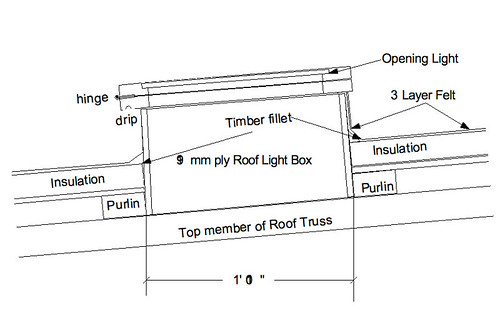

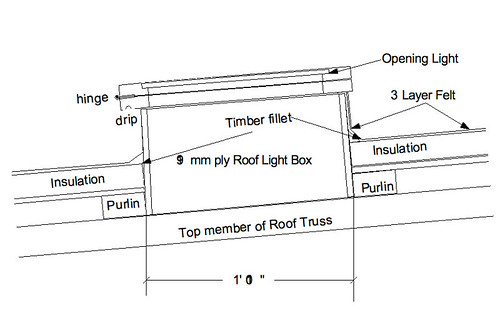

This stripped area shown is where I propose to install a Roof Light, directly above my Radial Arm Saw. (see drawing)

But before I sart stripping I must complete the roof light. Intended to start this weekend but all I got was rain.

As this section of the Forum is called “projects and mistakes” and I have

Made a few, mistakes in particular, I thought it would also give an opportunity show my home workshop and progress in renewing the roof and………….

Friends and relations in the North are interested and this is a good way of letting them know.

I have been in this property for two years now and the shed (workshop) was here at the bottom of the garden.

The shed was covered with rampant clematis, honey suckle and a viscous berberis. Some was growing inside the shed through the corrugations and gaps in the cladding. The door being difficult to open and close so, a pruning, repair job was in order. Fascias erected, trellising to tie the plants back and what I think are called Brea Solais fixed over the doors and windows.

Now the problem...

A Leaking Roof

This is a view on the under side showing a joint, 50mm from the purlin, a 70mm x 50mm timber laid on the flat.

You will observe some foam filler at the eaves which I used instead of the proprietary PVC strip filler which at a £1.00 is more expensive than a £5.00 can of foam. How much this has contributed to my problem not sure. The foam sets rigid, the strip foam filler is flexible and would possibly have sprung back when the snow melted. Also thought that when the foam continued expanding when setting would push the sheets upwards, but it didn’t. Does keep the insect out though and the spiders in, who are reduced in numbers and very thin.

View to the other Truss where there is also a sheet edge joint. You can see daylight here which did not come out on the photo.

This stripped area shown is where I propose to install a Roof Light, directly above my Radial Arm Saw. (see drawing)

But before I sart stripping I must complete the roof light. Intended to start this weekend but all I got was rain.