MarkDennehy

Established Member

Hi folks,

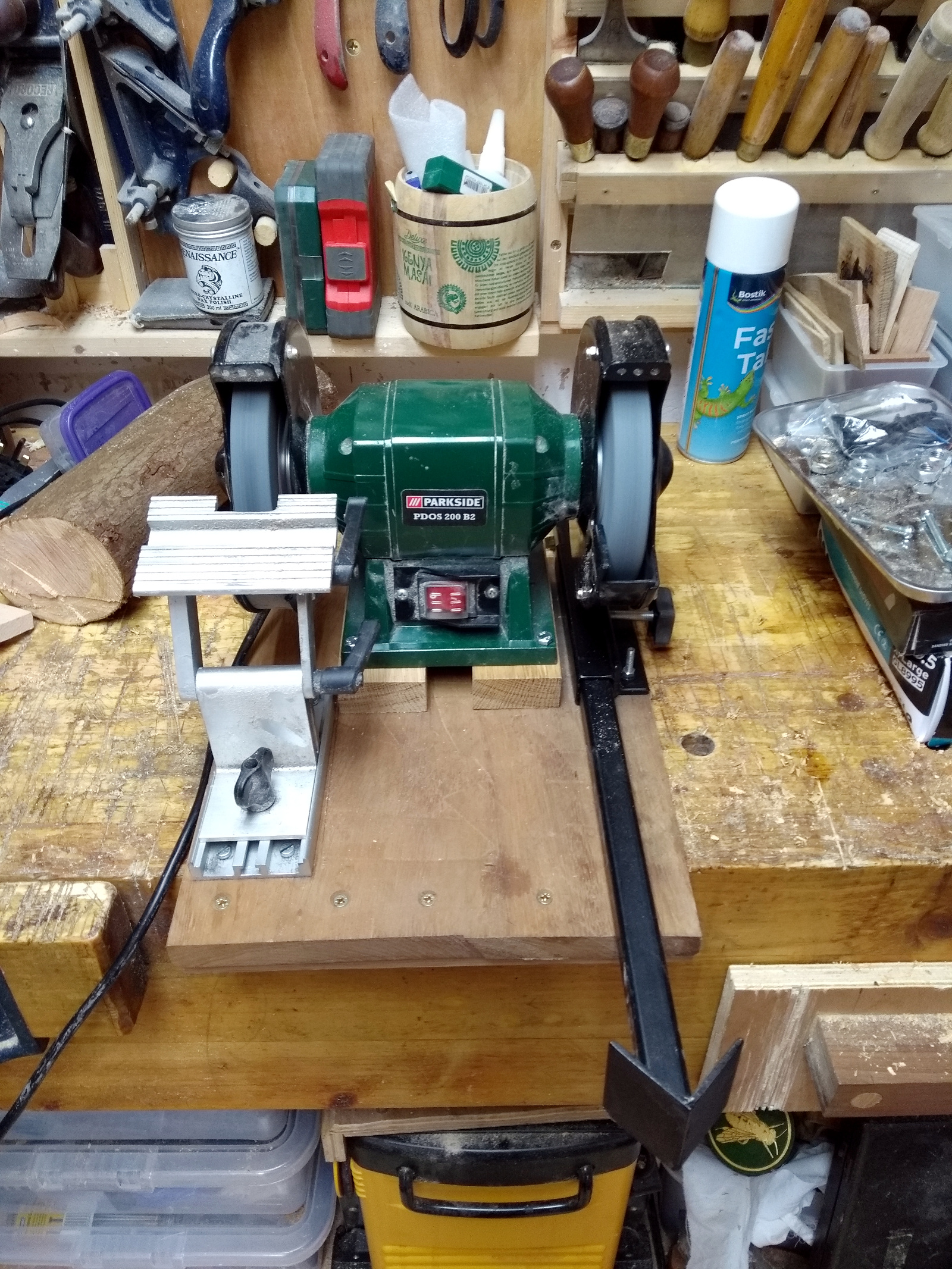

Quick question - I'm making a right dogs breakfast out of my turning tools because I got a cheap copy of a wolverine jig and not having white wheels on a standard grinder didn't help. I've swapped out the carborundum wheels for aluminium oxide, and at some point I'll swap a slow speed grinder in for the normal one I have (and if I win the lotto I might get a CBN wheel), but the jig is driving me demented and it's reached the point where it's not usable for two of the gouges anymore (one gouge is out of flute under the holding clamp and just spins in the jig, the other is a pretty steep angle and the jig has to be so close to the wheel that you grind both gouge and jig at the same time). And the ones it will sharpen, it's sharpened asymmetrially because it let the gouge twist in the clamp so the arc of the flute and the arc of the bevel do not share a centerline.

So the jig has to be replaced.

Has anyone used the BGK-400 kit from axminster or have thoughts on using the tormek rest and jigs with a grinder instead of a tormek?

A tormek itself won't fit in the shed (also water's too messy) and a proedge would be an absolute monster of a thing to store in there as well so they're no in the picture, at least for the moment. Which left me with either a real wolverine/oneway type of jig, or the tormek jig and bar. Watching Axminister's demo of the tormek jigs, they seemed very solid tooling, and I can get them locally here, but the law of demos states demos are mainly smoke and mirrors so I was hoping someone who's used them for real might give an opinon?

Thanks in advance,

Quick question - I'm making a right dogs breakfast out of my turning tools because I got a cheap copy of a wolverine jig and not having white wheels on a standard grinder didn't help. I've swapped out the carborundum wheels for aluminium oxide, and at some point I'll swap a slow speed grinder in for the normal one I have (and if I win the lotto I might get a CBN wheel), but the jig is driving me demented and it's reached the point where it's not usable for two of the gouges anymore (one gouge is out of flute under the holding clamp and just spins in the jig, the other is a pretty steep angle and the jig has to be so close to the wheel that you grind both gouge and jig at the same time). And the ones it will sharpen, it's sharpened asymmetrially because it let the gouge twist in the clamp so the arc of the flute and the arc of the bevel do not share a centerline.

So the jig has to be replaced.

Has anyone used the BGK-400 kit from axminster or have thoughts on using the tormek rest and jigs with a grinder instead of a tormek?

A tormek itself won't fit in the shed (also water's too messy) and a proedge would be an absolute monster of a thing to store in there as well so they're no in the picture, at least for the moment. Which left me with either a real wolverine/oneway type of jig, or the tormek jig and bar. Watching Axminister's demo of the tormek jigs, they seemed very solid tooling, and I can get them locally here, but the law of demos states demos are mainly smoke and mirrors so I was hoping someone who's used them for real might give an opinon?

Thanks in advance,