JFC":1n0ycedb said:

I think I would have to change the spindle on my machine [a Bursgreen RS] to do door tenons . Is this an option ?

Hi Jason

The manufacturer's spec. on the BRS from 1959 says the top piece comes in 1in diameter with options of 3/4in or 1-1/4in sizes. The spec. also quotes:

"

Included in the Price

Motor and starter,

solid loose top piece 1in diameter, pair grooved cutter collars 2-1/2in in diameter, 4 spacing sleeves, fence, set of spanners and tin of lubricant"

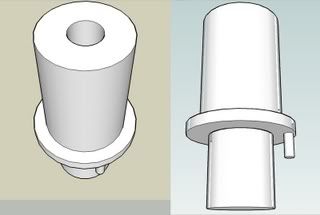

I've seen a reference in one of the Wadkin tooling catalogues of the period to French top pieces being available as well, so I'd crank-up the spindle as far as it will go and take a good look. Knowing Wadkin the spindle could possibly have been available either as a fixed spindle or a removable one :roll: ....... If it is removable the base of the spindle will probably either have a locking ring requiring a C-spanner to remove it or will have a locking ring with two flats for a 40 to 50mm open-ended wrench (it'll be Whitworth in all probability, so not metric, but it's in that size range). Lock the spindle and knock off the retaining nut and the ring will lift off followed by the spindle top piece. Another method involves a long nut secured the drive pulley from beneath - not nice to get at on an RS/BRS if that's the case. Unfortunately I can't say what design of top piece is used - earlier Wadkins with removable top pieces often use a parallel shank top piece with a square shoulder and a drive pin on one side - but as this machine was designed in Sagar days (pre-Wadkin), who knows? A stub top piece for a Wadkin would look something like this (sorry, no photos coz I'm on SCM which uses a Morse Taper #5):

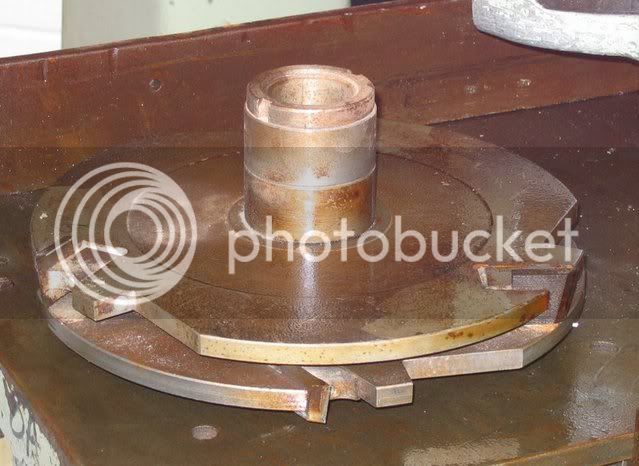

The top portion of a stub tenon should be about 50mm high (depending on the height of your cutter, of course) x whatever diameter is the bore of your spindle moulder. A good engineering firm should be able to turn you up a replacement stub top piece with an M12 or M16 threaded hole in the top to take the countersunk head cap screw you'll need to hold the washer supplied with some Whitehill cutters (ask Whitehill for dimensions). You can see the recess clearly in this photo of a standard Whitehill pinned Euro block (it says AXminster, but it's just a re-badged Whitehill):

Roger Sinden":1n0ycedb said:

Looking at the tenoning heads from Axminster aka Whitehill, they don't appear to have a recess for fixing and so how can you fly the stock over the top ? Maybe you can't with this type of head?

Do you have any reference to the Whitehill Combi head in your picture. Can't locate it on the Whitehill site.

Sorry Roger, you'll need to ring them and request the latest catalogue as the web site is well out of date. The now do 2- and 4-cutter rebate blocks as well as two designs of combi block

Whitehill 100mm x 40 high pinned Euro blocks (like the one shown above) are normally supplied as standard with a recess and a hold-down "washer" - to get this on their combi heads and rebate heads you may need to place a special order with them at a small extra charge, but they will do it as this is the method of holding used on the cutter blocks they make for both the Sedgwick and Multico single-end tenoners.

Above: My Whitehill 4-cutter 125mm diameter combi rebating and profiling block

One thing I would recommend is going for alloy blocks on smaller spindle moulders as the machine will be better able to spin them up and brake them to a halt

Scrit