pobo

Established Member

hi all. just finished bench build thought it would be nice to share some WIP pics.

top is made from beech block kitchen worktop and mdf to ad waight and strength, picked it up from b&q from some of their scraps

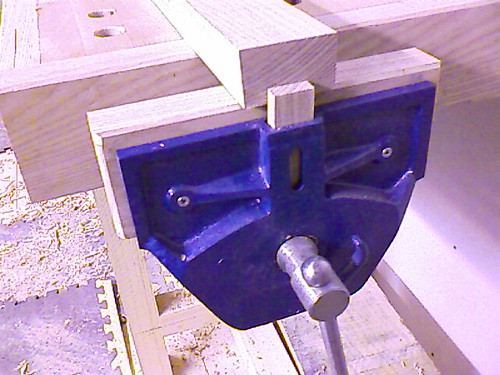

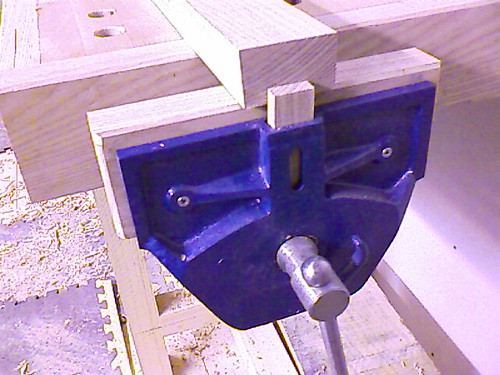

now with new vise from rutland, bargin at £25 each and they work really well

here i'm attaching the vise you can see the beech mdf sandwich (screw were replaced with bolts later.

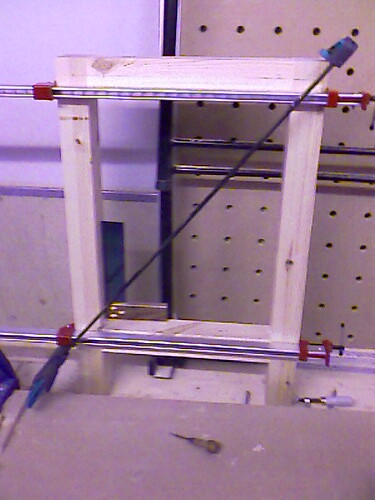

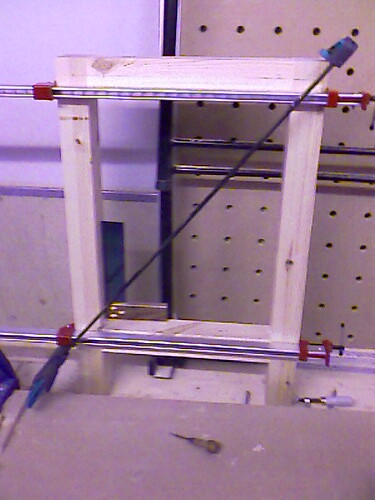

time for the legs, simple made from soft par (redwood i think). no m/t thou cheated and used biscuits

all together now, just want to turn it over

turning it over, hurray i have workbench and i'm luck not to have a bad back, already weights alot.

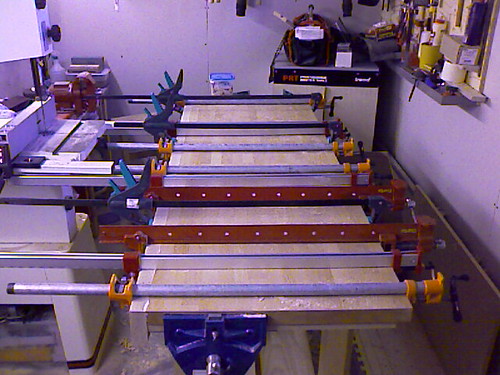

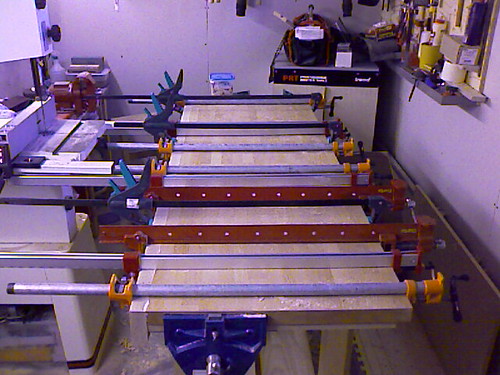

time for glueing up the front edge, glad i have all these clamps

and some more clamping

and now for the final product

using pine dowls for dogs

and replaced metal vise dog with wooden one to prevent damaging of wood

and built a bay at the end for my mess to collect

so i'm quite happy with the out come. as ever not what i planed.

heres some idea about costing

beech top 6ft x 2 ft x 40mm £10 (off cut from B&Q)

mdf two large scraps £8 (B&Q again)

vise x 2 = £50

ash for edging £22 for 12 foot of 1 1/2" x8" ( still have over haft left)

PAR for legs £30 (think i was ripped a bit on this one)

bolts £8.50 (just 92 spare)

total £128.50

i very happy with how sturdy and solid it is, and the fact it has a 58mm top is good. i have problems with a ache in the back at times so make it 960mm tall( about 100mm tall then the average) and it really works well for my hight(6'3").

i have a question

what do people think would be the best finish

if anyone need a new bench i really recommend building your own, i managed it with only a band saw, router, cordless and hand tool

please let me know your thoughts

ps a thank you to slim for his "how to" with posting flickr pictures.

pete

top is made from beech block kitchen worktop and mdf to ad waight and strength, picked it up from b&q from some of their scraps

now with new vise from rutland, bargin at £25 each and they work really well

here i'm attaching the vise you can see the beech mdf sandwich (screw were replaced with bolts later.

time for the legs, simple made from soft par (redwood i think). no m/t thou cheated and used biscuits

all together now, just want to turn it over

turning it over, hurray i have workbench and i'm luck not to have a bad back, already weights alot.

time for glueing up the front edge, glad i have all these clamps

and some more clamping

and now for the final product

using pine dowls for dogs

and replaced metal vise dog with wooden one to prevent damaging of wood

and built a bay at the end for my mess to collect

so i'm quite happy with the out come. as ever not what i planed.

heres some idea about costing

beech top 6ft x 2 ft x 40mm £10 (off cut from B&Q)

mdf two large scraps £8 (B&Q again)

vise x 2 = £50

ash for edging £22 for 12 foot of 1 1/2" x8" ( still have over haft left)

PAR for legs £30 (think i was ripped a bit on this one)

bolts £8.50 (just 92 spare)

total £128.50

i very happy with how sturdy and solid it is, and the fact it has a 58mm top is good. i have problems with a ache in the back at times so make it 960mm tall( about 100mm tall then the average) and it really works well for my hight(6'3").

i have a question

what do people think would be the best finish

if anyone need a new bench i really recommend building your own, i managed it with only a band saw, router, cordless and hand tool

please let me know your thoughts

ps a thank you to slim for his "how to" with posting flickr pictures.

pete