I just thought I'd pass on this useful bit of info from some Lenox (American Saw) tech. data sheets I've recently received (I've removed the metalwork stuff for clarity and added some of my own comments, too :roll: ):

For fast ripping - 1 to 2 tpi

For rough cuts - 2 tpi

For general cutting - 3 tpi

For fine and smooth cutting - 4 tpi and above

If having difficulty choosing between two pitches, the finer of the two will generally give better blade life but cut more slower (so must be fed more slowly).

The following applies to Lenox blades, but is also generally applicable to any bandsaw blades:

Tooth Style

Regular Tooth - Straight faced tooth with deep gullets to rake out chips. This style is used for general wood cutting

Hook Tooth - Widely spaced teeth and deep gullets with teeth that have a ten degree undercut face which helps to dig in and take a good cut while the gullets tend to curl the chips. This type is good for harder woods and many plastic operations. Available in raker set only.

Skip Tooth - Very similar to the hook tooth but characterized by a straight 90 degree tooth and a sharp angle at the junction of the tooth and gullet. This type tends to break up the chips. This style is popular in wood cutting but cuts less aggressively than hook tooth because iof the smaller gullet. Available in raker set only.

Variable Tooth - (Bi-Metal or TCT only) Also known as vari-tooth or broach tooth, this tooth has varying set angles and gullet depths. The variable tooth cutting edge reduces vibration while the back absorbs the impact of cutting in and out of knot holes, slots, etc. It is useful for chatter-free sawing of extremely hard timbers such as ebony.

Tooth Set

Raker Set

Three tooth sequence (left, right, straight), uniform set angle.

Vari-Raker Set

Multi-tooth sequence depending on tooth, varying set angle, 14/18 Vari-tooth has random wavy set.

Alternate Set

Every tooth set in an alternating sequence.

Wavy Set

Groups of teeth set to each side. Teeth have varying amounts of set in a controlled pattern. Generally only used in fine tooth pattern for metals and some plastics, such as phenolics, etc. Tends to clog in wood.

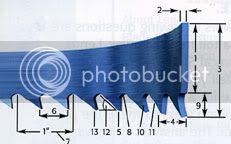

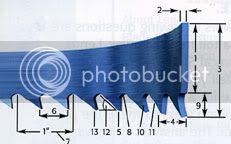

Blade Terminology

1 Blade Back - The body of the blade not including tooth portions.

2. Thickness - The thickness of the blade.

3. Width - The nominal dimension of a sawblade as measured from the tip of the tooth to the back of the band.

4. Set - The bending of the teeth to right or left to allow clearance of the back through the cut.

5. Tooth - The cutting portion of a saw blade.

6. Tooth Pitch - The distance from the tip of one tooth to the tip of the next tooth.

7. T.P.I. - The number of teeth per inch.

8. Gullet - The curved area at the base of the tooth.

9. Gullet Depth - The distance from the tooth tip to the bottom of the gullet.

10. Tooth Face - The surface of the tooth on which the chip is formed.

11. Tooth Back - The surface of the tooth opposite the tooth face.

12. Tooth Rake Angle - The angle of the tooth face measured with respect to a line perpendicular to the cutting direction of the saw.

13. Tooth Face - The cutting edge of the saw tooth.

You don't often see this sort of thing published, so I though I'd pass it on

Scrit

For fast ripping - 1 to 2 tpi

For rough cuts - 2 tpi

For general cutting - 3 tpi

For fine and smooth cutting - 4 tpi and above

If having difficulty choosing between two pitches, the finer of the two will generally give better blade life but cut more slower (so must be fed more slowly).

The following applies to Lenox blades, but is also generally applicable to any bandsaw blades:

Tooth Style

Regular Tooth - Straight faced tooth with deep gullets to rake out chips. This style is used for general wood cutting

Hook Tooth - Widely spaced teeth and deep gullets with teeth that have a ten degree undercut face which helps to dig in and take a good cut while the gullets tend to curl the chips. This type is good for harder woods and many plastic operations. Available in raker set only.

Skip Tooth - Very similar to the hook tooth but characterized by a straight 90 degree tooth and a sharp angle at the junction of the tooth and gullet. This type tends to break up the chips. This style is popular in wood cutting but cuts less aggressively than hook tooth because iof the smaller gullet. Available in raker set only.

Variable Tooth - (Bi-Metal or TCT only) Also known as vari-tooth or broach tooth, this tooth has varying set angles and gullet depths. The variable tooth cutting edge reduces vibration while the back absorbs the impact of cutting in and out of knot holes, slots, etc. It is useful for chatter-free sawing of extremely hard timbers such as ebony.

Tooth Set

Raker Set

Three tooth sequence (left, right, straight), uniform set angle.

Vari-Raker Set

Multi-tooth sequence depending on tooth, varying set angle, 14/18 Vari-tooth has random wavy set.

Alternate Set

Every tooth set in an alternating sequence.

Wavy Set

Groups of teeth set to each side. Teeth have varying amounts of set in a controlled pattern. Generally only used in fine tooth pattern for metals and some plastics, such as phenolics, etc. Tends to clog in wood.

Blade Terminology

1 Blade Back - The body of the blade not including tooth portions.

2. Thickness - The thickness of the blade.

3. Width - The nominal dimension of a sawblade as measured from the tip of the tooth to the back of the band.

4. Set - The bending of the teeth to right or left to allow clearance of the back through the cut.

5. Tooth - The cutting portion of a saw blade.

6. Tooth Pitch - The distance from the tip of one tooth to the tip of the next tooth.

7. T.P.I. - The number of teeth per inch.

8. Gullet - The curved area at the base of the tooth.

9. Gullet Depth - The distance from the tooth tip to the bottom of the gullet.

10. Tooth Face - The surface of the tooth on which the chip is formed.

11. Tooth Back - The surface of the tooth opposite the tooth face.

12. Tooth Rake Angle - The angle of the tooth face measured with respect to a line perpendicular to the cutting direction of the saw.

13. Tooth Face - The cutting edge of the saw tooth.

You don't often see this sort of thing published, so I though I'd pass it on

Scrit