Just thought i'd share this cunning little discovery with you all.

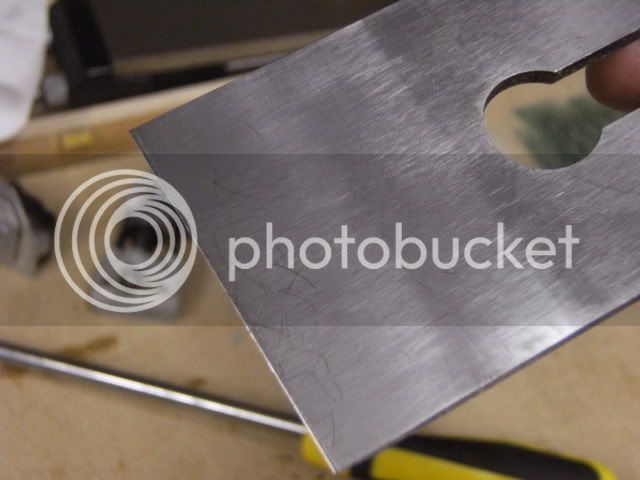

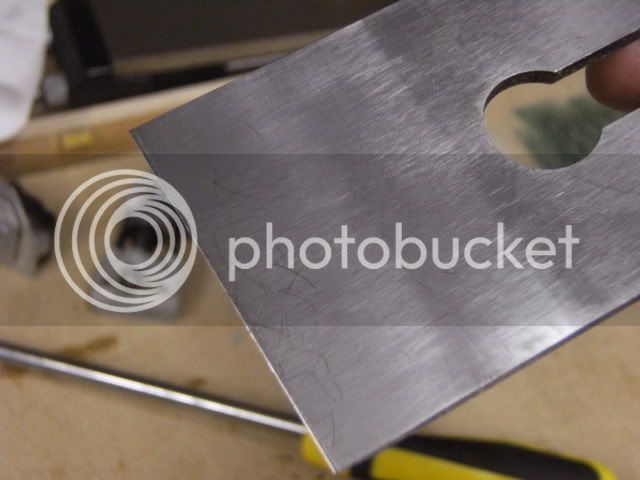

What you are looking at is a blade with two (yes, two) honing guides attached - one to each side of the blade.

First I attach the Eclipse style guide in its position to hone the "normal" microbevel. I then attach a second guide behind it, with the wheel operating on the opposite face. The two guides are then used alternately through the various grits of your chosen sharpening method to create a nice polished microbevel & back bevel. In my case this is Trend fine stone, green honing soap, white honing soap.

Here is the back bevel being created on the trend stone.

And being polished on the honing soap

The resultant microbevel

Result - a nice sharp edge!

Cheers

Karl

What you are looking at is a blade with two (yes, two) honing guides attached - one to each side of the blade.

First I attach the Eclipse style guide in its position to hone the "normal" microbevel. I then attach a second guide behind it, with the wheel operating on the opposite face. The two guides are then used alternately through the various grits of your chosen sharpening method to create a nice polished microbevel & back bevel. In my case this is Trend fine stone, green honing soap, white honing soap.

Here is the back bevel being created on the trend stone.

And being polished on the honing soap

The resultant microbevel

Result - a nice sharp edge!

Cheers

Karl