Does anyone know if there is a jig like this one available in the uk http://www.robohippy.net/store/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Angle setting jig

- Thread starter murphy

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

It looks similar to sorby’s sharpening jig

Ian

Ian

There is this: http://www.axminster.co.uk/veritas-grin ... est-600320 comes with a setting tool.

Mike

Mike

Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 76

They're silly prices. I have the old Axminster one (very similar to the Veritas, but natural colour anodising). It additionally has a sliding tool holder (what the groove is actually for), and an in-out sliding track that you mount it with, which is handy

The only issue is that they are aluminium, and carborundum grit and steel particles dig in and stop any sliding! That may be why the Veritas version doesn't seem to have the tool carrier, nor a sliding track to mount it.

I'm sure I didn't pay 40 quid, either. (update: The Veritas one does have the tool carrier, but it's sold separately -- 60 quid for the set!)

Mine gets a lot of use for freehand shaping, etc, but it probably wouldn't survive long if I was a turner.

It must be reasonably easy to make with some steel web off-cuts (angle iron). I nearly made one myself, but the Axy one was on offer, so it wasn't worth the effort. $95 for that American one is just taking the you-know-what.

The only issue is that they are aluminium, and carborundum grit and steel particles dig in and stop any sliding! That may be why the Veritas version doesn't seem to have the tool carrier, nor a sliding track to mount it.

I'm sure I didn't pay 40 quid, either. (update: The Veritas one does have the tool carrier, but it's sold separately -- 60 quid for the set!)

Mine gets a lot of use for freehand shaping, etc, but it probably wouldn't survive long if I was a turner.

It must be reasonably easy to make with some steel web off-cuts (angle iron). I nearly made one myself, but the Axy one was on offer, so it wasn't worth the effort. $95 for that American one is just taking the you-know-what.

Thank you all for the reply's, I went for the Veritas as it seems solid, the reason I wanted one like the American guy sells is you just put a pin in a hole to set the angle, which is very fast if you are changing angles all the time

Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 76

There are drawbacks to his system: the pin only does tool-rest tilt, NOT the actual ground angle

The point that the tool's edge hits the grinding wheel will change, and that alters the angle.

And to put it another way, the projection of the tip of the tool, beyond the grinding support, also affects the angle ground (as does the diameter of the wheel).

Best thing is to spend half an hour (in front of the telly - where I usually work this stuff out!) with pencil and paper, drawing diagrams, so you can see what affects what.

If the exact angle matters in practice, you probably need to make an angle protractor, so you can sight it with the tool bearing on the (stationary) wheel and adjust accordingly.

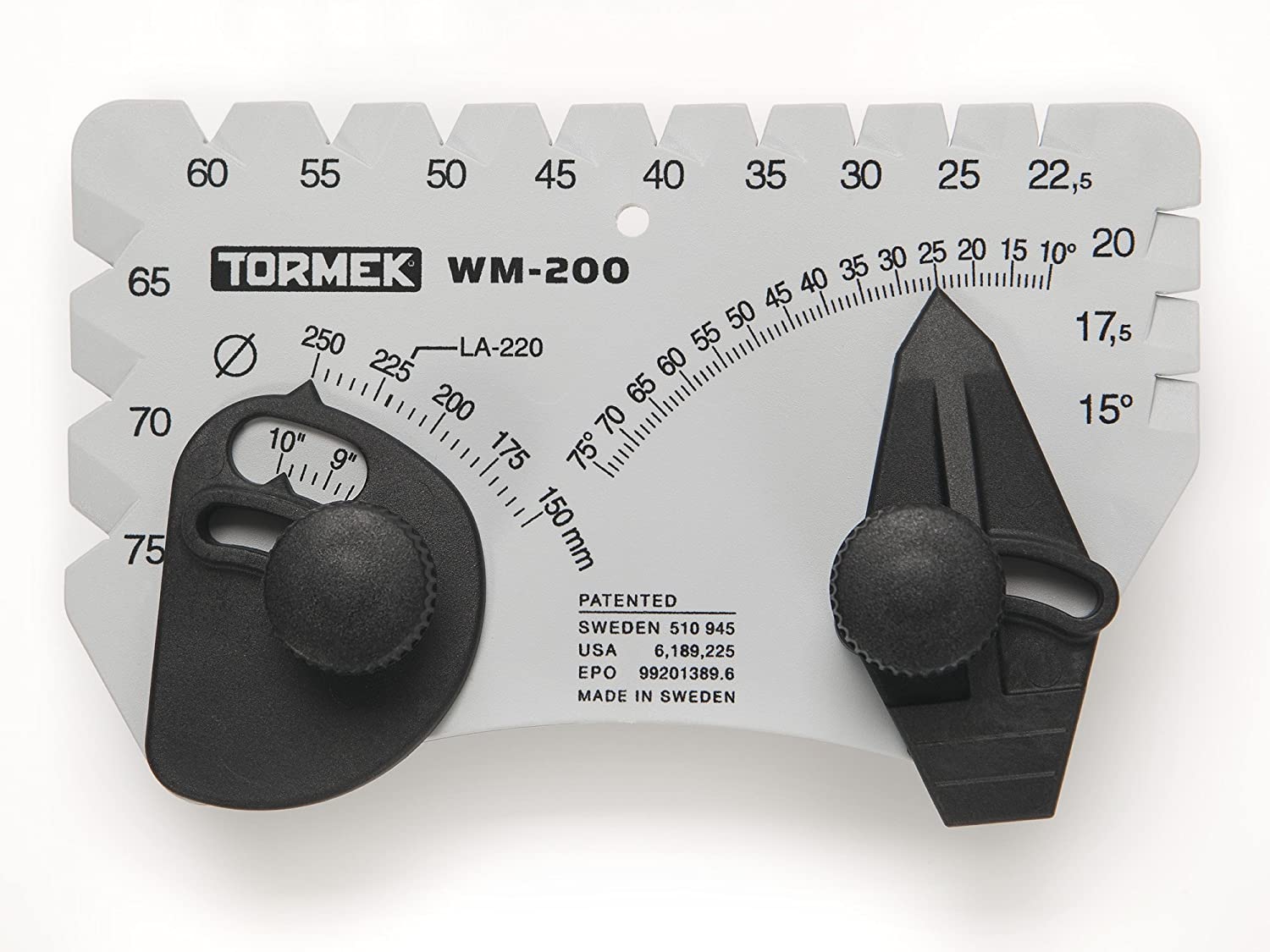

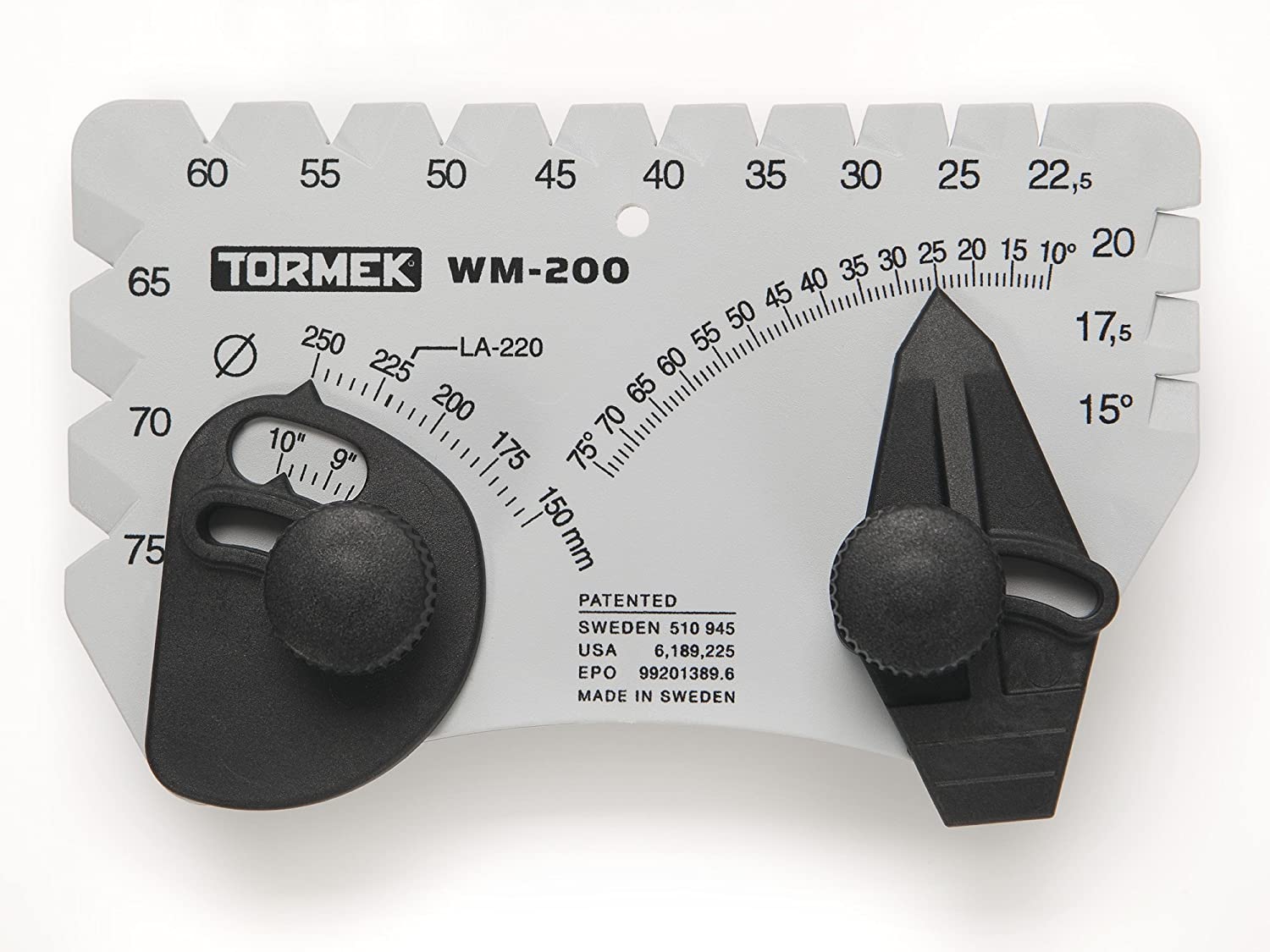

The Tormek-style angle guides (widely copied) that rest a flat on the tool, and a round bit on the wheel do work really well, but probably only work for wheel diameters larger than that on your fast grinder. You might calculate and make your own, but it's a bit of a faff and accuracy would be hard to achieve. I mean these things:

I've got one like the black one, but note that they don't adjust down to small grinding wheel diameters. I suppose you could shave a bit off the white quadrant and guesstimate it...

The point that the tool's edge hits the grinding wheel will change, and that alters the angle.

And to put it another way, the projection of the tip of the tool, beyond the grinding support, also affects the angle ground (as does the diameter of the wheel).

Best thing is to spend half an hour (in front of the telly - where I usually work this stuff out!) with pencil and paper, drawing diagrams, so you can see what affects what.

If the exact angle matters in practice, you probably need to make an angle protractor, so you can sight it with the tool bearing on the (stationary) wheel and adjust accordingly.

The Tormek-style angle guides (widely copied) that rest a flat on the tool, and a round bit on the wheel do work really well, but probably only work for wheel diameters larger than that on your fast grinder. You might calculate and make your own, but it's a bit of a faff and accuracy would be hard to achieve. I mean these things:

I've got one like the black one, but note that they don't adjust down to small grinding wheel diameters. I suppose you could shave a bit off the white quadrant and guesstimate it...

£199.00

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£34.99 (£3.50 / count)

£39.99 (£4.00 / count)

VonHaus Chisel Set - 10pcs Woodworking Tools Set - Wood Carving Tools, Wood Chisel Sets with Sharpening Stone, Honing Guide and Storage Case

VonHaus UK

£15.99 (£1.60 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£10.19 (£0.39 / count)

£11.99 (£0.46 / count)

Nicpro Carpenter Pencil with Sharpener, Mechanical Carpenter Pencils Set with 26 Refills, Case, Deep Hole Marker Construction Pencils Heavy Duty Woodworking Pencils for Architect (Black, Red)

NicproShop EU

£10.10

£15.48

Portwest Browguard with Clear Visor, Size: One Size, Colour: Clear, PW91CLR

Amazon.co.uk

£16.99

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£9.99 (£1.00 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

CHJ

Established Member

I use simple 'lay-on' angle templates to judge optimum wheel contact nearest the angle I'm aiming at:-

post499317.html#p499317

post499317.html#p499317

Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 76

That looks like a lot less fuss, Chas, and probably just as good as the plastic thingy!

CHJ

Established Member

Well it's done me for the last 10 yrs. whenever angles seem to be drifting too far away from 'the norm'Eric The Viking":3giwkmkt said:That looks like a lot less fuss, Chas, and probably just as good as the plastic thingy!

It's like the simple wooden tool rest, does the job and leaves more pocket money for the important bits with cutting edges on them, obviously over the years and the odd chance acquisition, pocket money boost etc. other little additions arrive that can more readily meet a specific need but none are 'essential'.

Similar threads

- Replies

- 18

- Views

- 886

- Replies

- 20

- Views

- 1K