woodbloke

Established Member

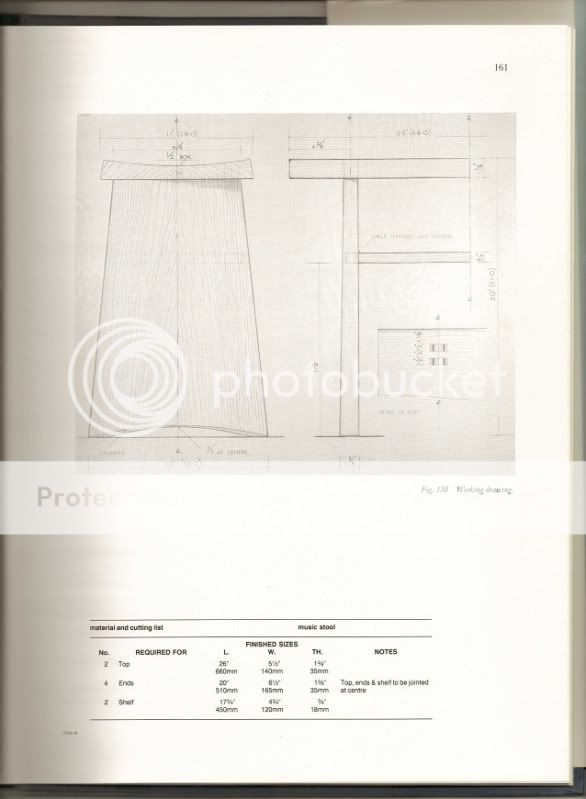

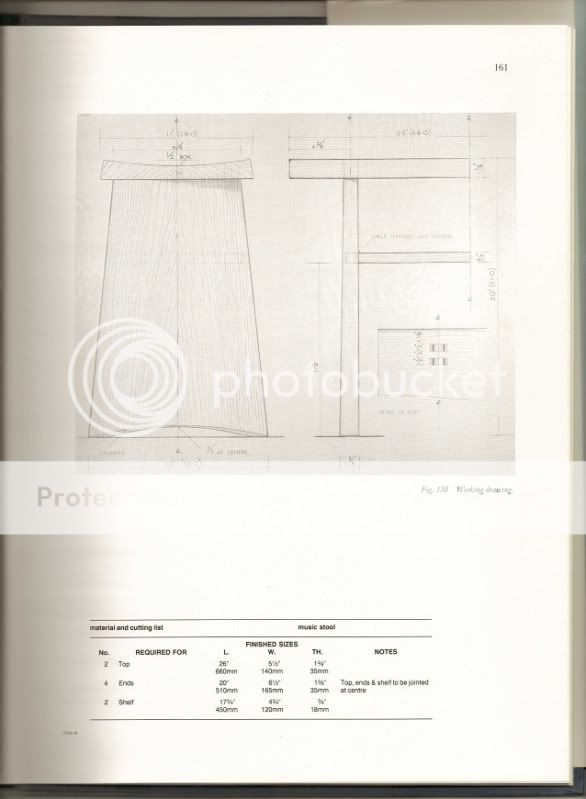

Having got an oddment of material left over from my main project, I've decided to crack on with one of these, which has long been on my 'tuit' list:

which is one of Alan Peter's designs from his book 'Cabinet Making - the Professional Approach' I didn't quite have enough material for a full size stool so my one's been scaled down to threequarter size.

Material is air dried English Oak...none of your AWO here all jointing will be exposed and wedged. I got all the main pieces glued together today, so next will be marking out the joints. Nick Gibbs in BW recently made something similar iIrc - Rob

all jointing will be exposed and wedged. I got all the main pieces glued together today, so next will be marking out the joints. Nick Gibbs in BW recently made something similar iIrc - Rob

which is one of Alan Peter's designs from his book 'Cabinet Making - the Professional Approach' I didn't quite have enough material for a full size stool so my one's been scaled down to threequarter size.

Material is air dried English Oak...none of your AWO here