I've been 'out of action' all weekend with a damaged back, and it's been driving me nutty. Anyway, by this lunchtime, I was able to stand again, and, bored, wandered into the garage, where my eyes fell on one of my Grandfather's shoulder planes. This one is around 100 years old, but had at some point been ruined by someone 'thinning' the bottom half, so that the wood was about 1/8th inch wider at the top than the bottom - so the blade 'stuck out' either side. Odd, because he was a patternmaker: maybe he gave it to an apprentice who ruined it...

So, with my eyes on some straight grained cherry that I've had stored for 15 years or so, I decided to have a quick play. First task was to rip the lower half off: did this on the bandsaw, which left me with this:

Having done that, I set a marking gauge to the thickness of the plane, and scored a piece of cherry. This was then cut to width on the bandsaw. Leaving it 'deeper' than the projected mouth, I glued and clamped this to the body:

Next I planed the cherry flush on either side, and cut the ends to length. After this, I extended the line of the bed with a knife onto the cherry. The fun part was that it's not a 'rectilinear' plane - the blade is skewed for a better cut. Clamping the plane in the bench vice, I used a Japanese pull saw to make the cuts, eyeballing the bed and and it's opposing face to get the geometry right:

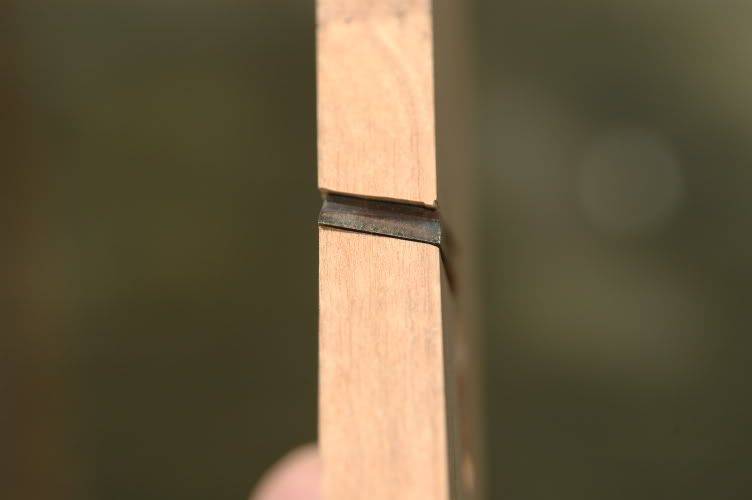

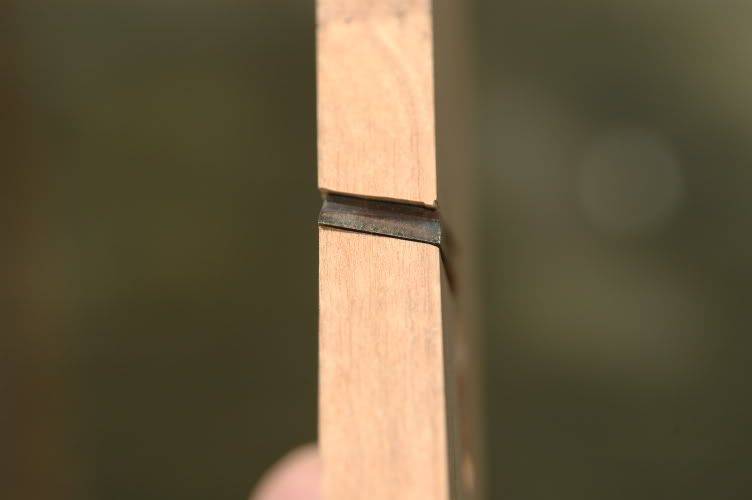

Then came some jointing of the bottom, until the mouth was wide enough for the (original) blade. This had to go quite carefully, as I wanted a nice tight mouth. Here's the result - I'm quite pleased:

For those who want to nitpick, yes, the back of the bed there isn't perfect, but remember that this is a bevel down plane, so that last eigth of an inch has no locating function - all it does it strengthen the bed above it.

The last bit was a replacement wedge. I used cherry again, and the skew made it interesting to get the angles right: here's my result:

Finally, I shaped the wedge: I'm not overwhelmed by many traditional 'round-topped' wedges: the functional requirement is 3-fold: hold the iron in place, be hittable on the top to lock everything in place, and provide a surface to knock out of the plane. Accordingly, I shaped it with a sneck or knock for coming out, and a flat top. in line with the grain, for locking down. Here's the end result - all that's left is a night in danish oil, and I'm going to follow that with shellac, because I love using it:

Hope you found it interesting - oh yes - she cuts well...

So, with my eyes on some straight grained cherry that I've had stored for 15 years or so, I decided to have a quick play. First task was to rip the lower half off: did this on the bandsaw, which left me with this:

Having done that, I set a marking gauge to the thickness of the plane, and scored a piece of cherry. This was then cut to width on the bandsaw. Leaving it 'deeper' than the projected mouth, I glued and clamped this to the body:

Next I planed the cherry flush on either side, and cut the ends to length. After this, I extended the line of the bed with a knife onto the cherry. The fun part was that it's not a 'rectilinear' plane - the blade is skewed for a better cut. Clamping the plane in the bench vice, I used a Japanese pull saw to make the cuts, eyeballing the bed and and it's opposing face to get the geometry right:

Then came some jointing of the bottom, until the mouth was wide enough for the (original) blade. This had to go quite carefully, as I wanted a nice tight mouth. Here's the result - I'm quite pleased:

For those who want to nitpick, yes, the back of the bed there isn't perfect, but remember that this is a bevel down plane, so that last eigth of an inch has no locating function - all it does it strengthen the bed above it.

The last bit was a replacement wedge. I used cherry again, and the skew made it interesting to get the angles right: here's my result:

Finally, I shaped the wedge: I'm not overwhelmed by many traditional 'round-topped' wedges: the functional requirement is 3-fold: hold the iron in place, be hittable on the top to lock everything in place, and provide a surface to knock out of the plane. Accordingly, I shaped it with a sneck or knock for coming out, and a flat top. in line with the grain, for locking down. Here's the end result - all that's left is a night in danish oil, and I'm going to follow that with shellac, because I love using it:

Hope you found it interesting - oh yes - she cuts well...