IanB

Established Member

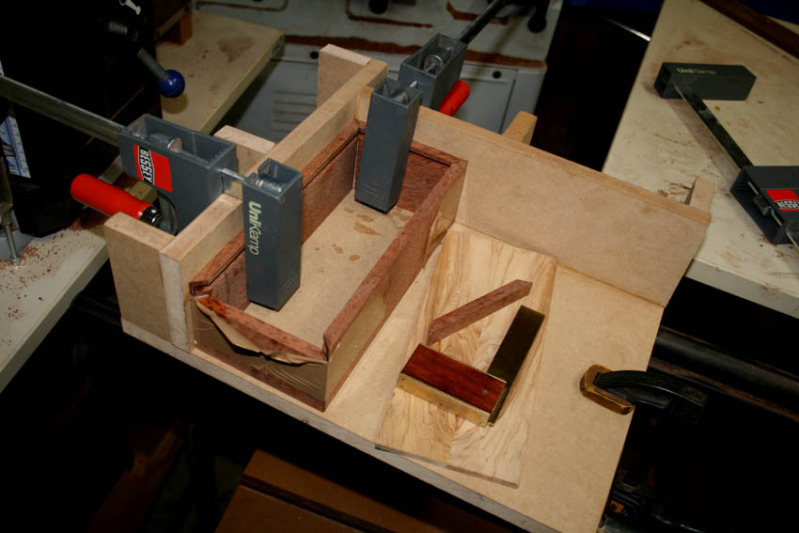

I'm having a go at making my first small box with mitred corners, but a couple of the corners slipped a little during the glue up. (I used masking tape on the joints but didn't seem to get a tight enough join, so added some clamps which I think is when the slippage took place).

So, is there a 'least worst' way to clean up the corners on the outside and remove the protruding edges and disguise it as best as possible? Plane, pare with a chisel, flush cut saw, sand, or something else? Or even plane a chamfer on all the corners?

So, is there a 'least worst' way to clean up the corners on the outside and remove the protruding edges and disguise it as best as possible? Plane, pare with a chisel, flush cut saw, sand, or something else? Or even plane a chamfer on all the corners?