RobertMP

Established Member

Well they were Oak kitchen cupboard doors but now they are two Adirondack garden chairs

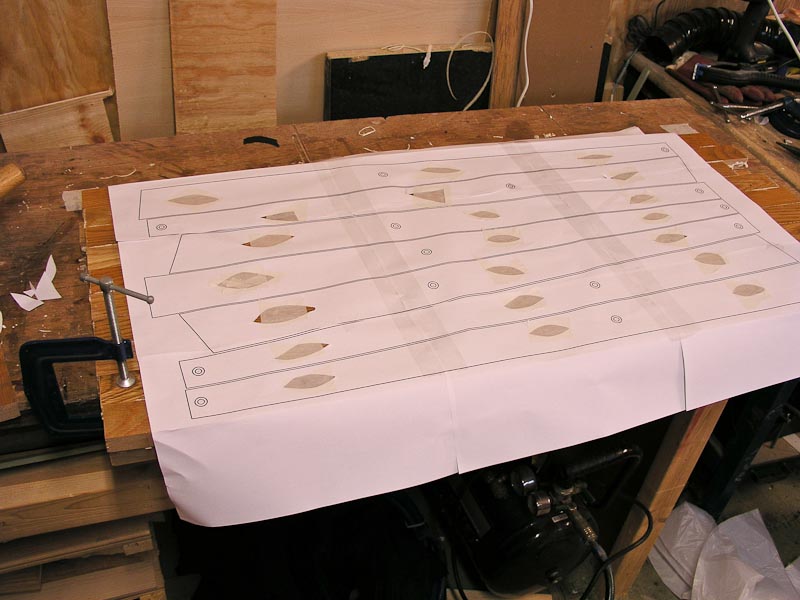

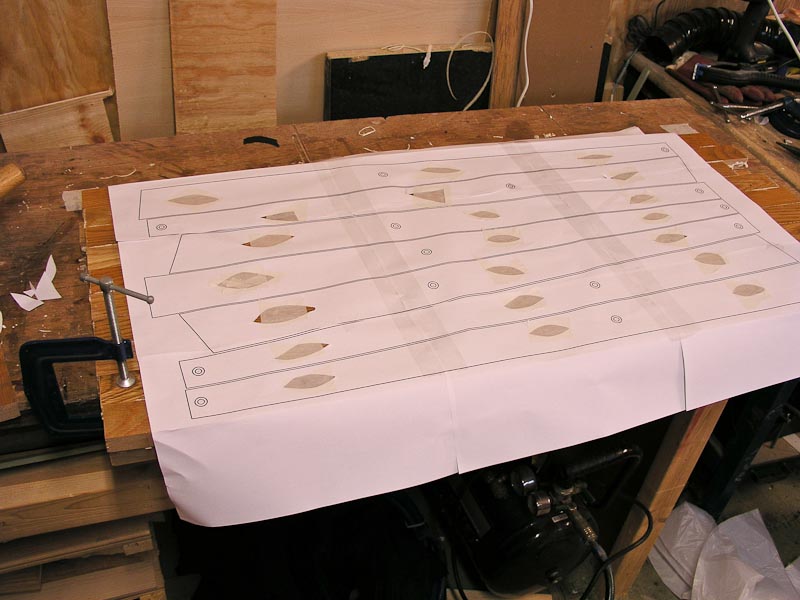

The panels inside the door were not big enough for most parts so I cut the rails into square ended and sided pieces and glued them into panels. The PU glue I used claimed it is suitable for immersion in sea water but I guess only time will tell. I taped a printout from sketchup onto the face ready to bandsaw two panel at once.

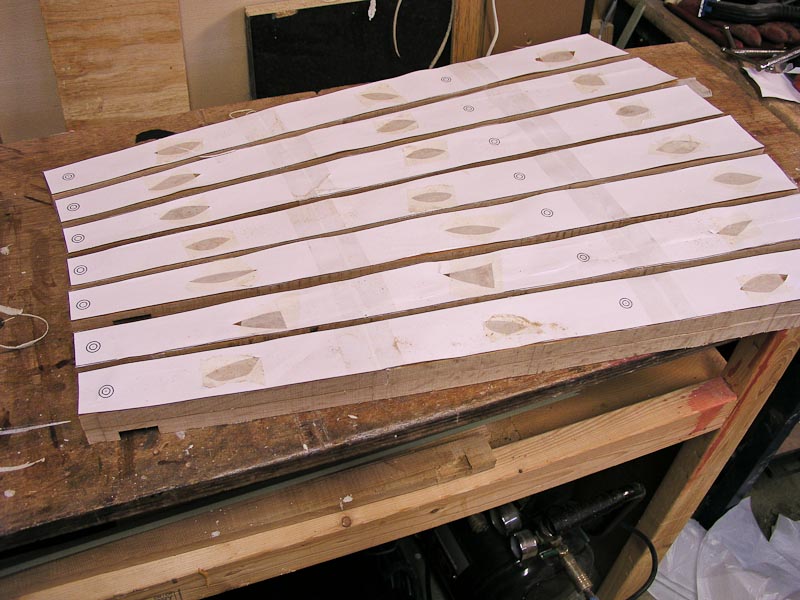

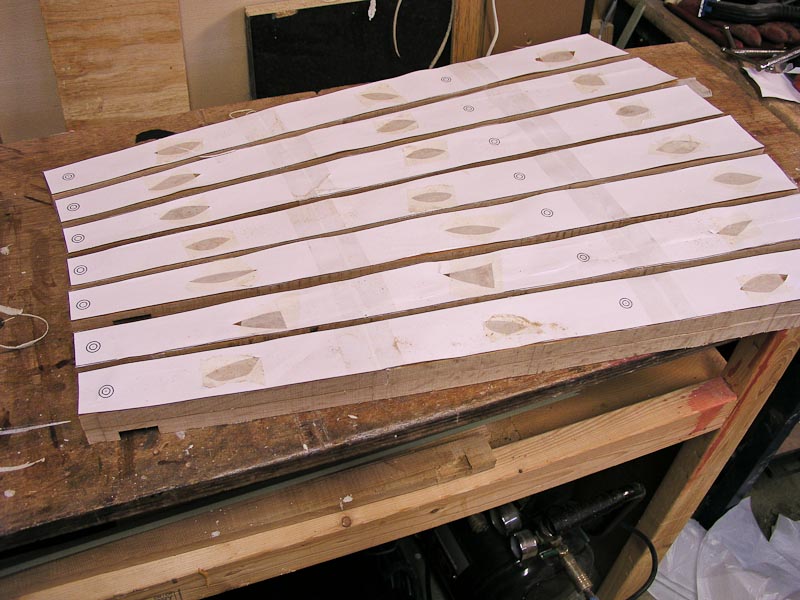

Kept all the holes on one side

After a bit of band sawing

Repeat as required and end up with a set of parts

Then after a bit of work on the planer thicknesser, router with 1/4" radius cutter, drill, belt sander and some filling where the cutouts break the edges followed by spraying with some reasonably priced yacht varnish from toolstation.....

I quite like that you can see its origins on the internal or back faces of the main side pieces and the back slats. The arms are arguably a bit on the thin side at 15mm thick but I have tried the ultimate test of sitting just on the arm and it felt solid enough.

The panels inside the door were not big enough for most parts so I cut the rails into square ended and sided pieces and glued them into panels. The PU glue I used claimed it is suitable for immersion in sea water but I guess only time will tell. I taped a printout from sketchup onto the face ready to bandsaw two panel at once.

Kept all the holes on one side

After a bit of band sawing

Repeat as required and end up with a set of parts

Then after a bit of work on the planer thicknesser, router with 1/4" radius cutter, drill, belt sander and some filling where the cutouts break the edges followed by spraying with some reasonably priced yacht varnish from toolstation.....

I quite like that you can see its origins on the internal or back faces of the main side pieces and the back slats. The arms are arguably a bit on the thin side at 15mm thick but I have tried the ultimate test of sitting just on the arm and it felt solid enough.