devonwoody

Established Member

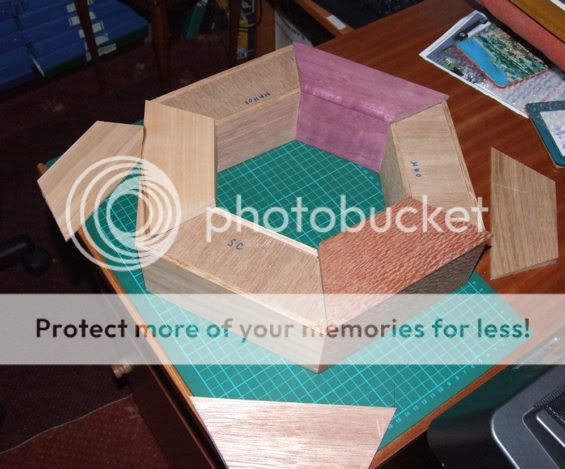

A type of lazy susan

--------------------------------------------------------------------------------

http://www.woodworkforums.ubeaut.com.au ... hp?t=55591

I had help form Australian forum members who kindly supplied a working drawing (using their cad program and also some trig experts.) which I blew up in PSP X1 and made a full sized poster.

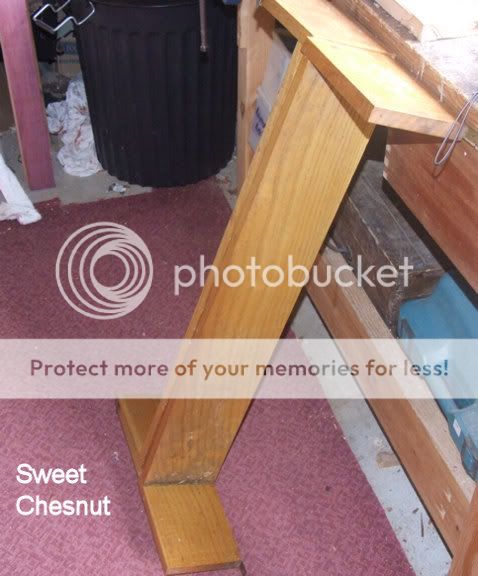

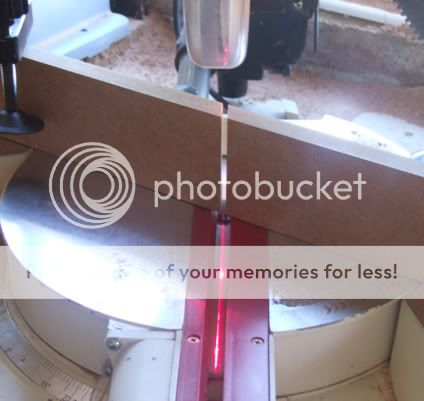

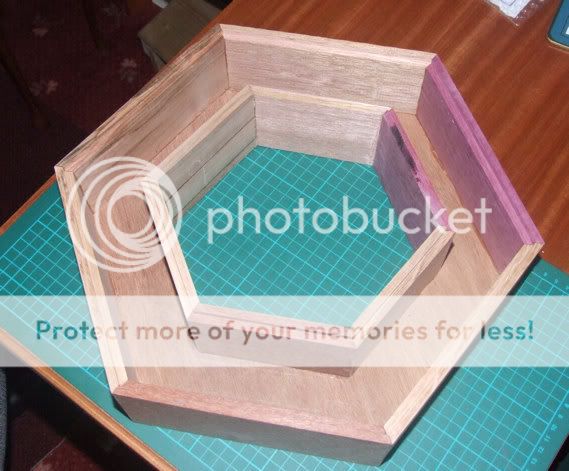

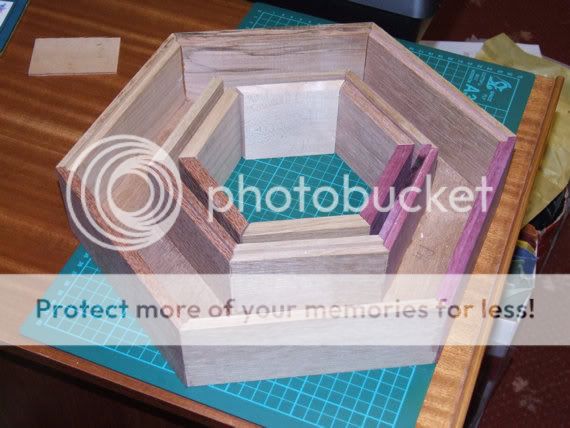

So am going to attempt a seven box project using a different species of timber for each section. I will most probably keep the setup as a fixed system to avoid turning it into a mobile feature and thus avoid balance problems. Also not going to glue each box until the outer ring has been completed incase cutting accuracy does not come at 100%(which I think would be very unlikely)

__________________

--------------------------------------------------------------------------------

http://www.woodworkforums.ubeaut.com.au ... hp?t=55591

I had help form Australian forum members who kindly supplied a working drawing (using their cad program and also some trig experts.) which I blew up in PSP X1 and made a full sized poster.

So am going to attempt a seven box project using a different species of timber for each section. I will most probably keep the setup as a fixed system to avoid turning it into a mobile feature and thus avoid balance problems. Also not going to glue each box until the outer ring has been completed incase cutting accuracy does not come at 100%(which I think would be very unlikely)

__________________