Derek Cohen (Perth Oz)

Established Member

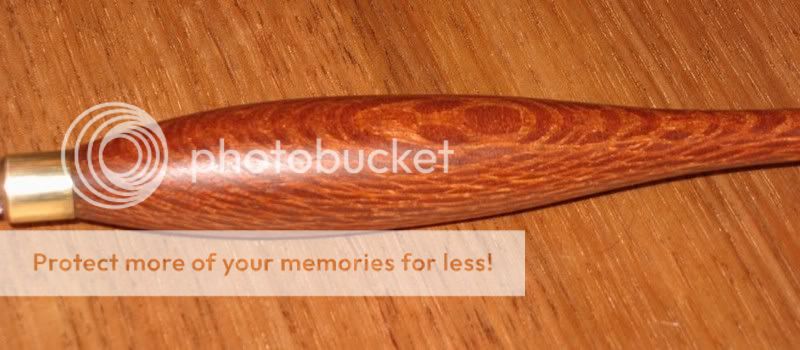

I have been refining a dovetail marking knive and scratch awl design over the past year, and I think that I am getting there.

The knife blades are HSS jigsaw blades that I surface grind and then double bevel. The awl blades are ground and hardened from concrete nails.

Here are a few recent examples:

A Jarrah set for a friend:

A She-oak set I kept for my own use (as I love the flaw):

Here are a couple of "harlequin" marking knives.

The first is in Jarrah and Olive wood:

And another in Jarrah and She-oak:

Oh, while I am showing these, here is a fishtail chisel in Tasmanian Blackwood for cleaning half-blind dovetails.

and another in She-oak:

Thanks for looking.

Regards from Perth

Derek

The knife blades are HSS jigsaw blades that I surface grind and then double bevel. The awl blades are ground and hardened from concrete nails.

Here are a few recent examples:

A Jarrah set for a friend:

A She-oak set I kept for my own use (as I love the flaw):

Here are a couple of "harlequin" marking knives.

The first is in Jarrah and Olive wood:

And another in Jarrah and She-oak:

Oh, while I am showing these, here is a fishtail chisel in Tasmanian Blackwood for cleaning half-blind dovetails.

and another in She-oak:

Thanks for looking.

Regards from Perth

Derek