devonwoody

Established Member

I have started a new box using lacewood.

This time I intend to have a drop down lid which has had rebates prepared prior to cutting off the lid from the bottom portion of the box.

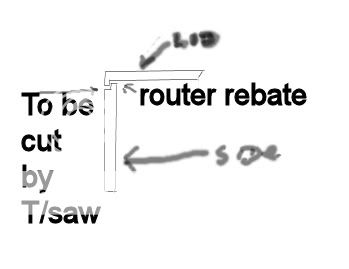

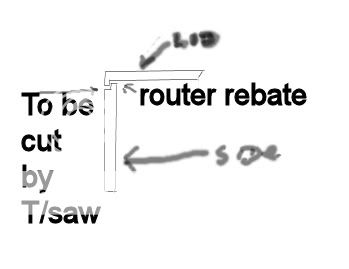

Freehand sketch below, I have not seen a box prepared previously in this manner but other members might tell me it is old hat. ..

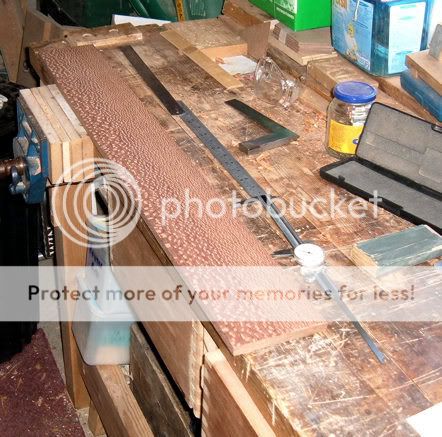

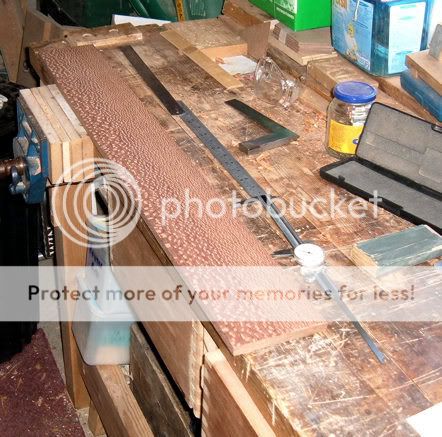

Picture of the 36” x 4 ½” 12mm prepared lacewood.

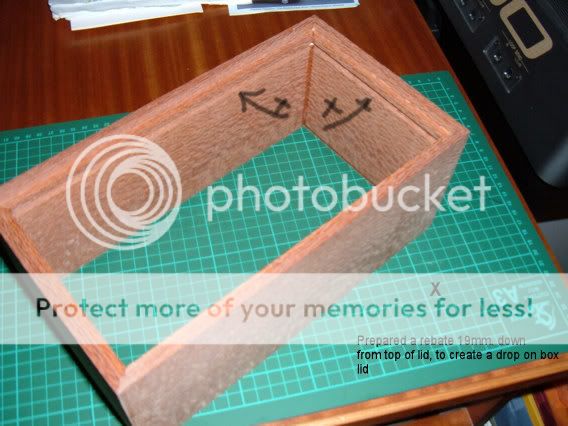

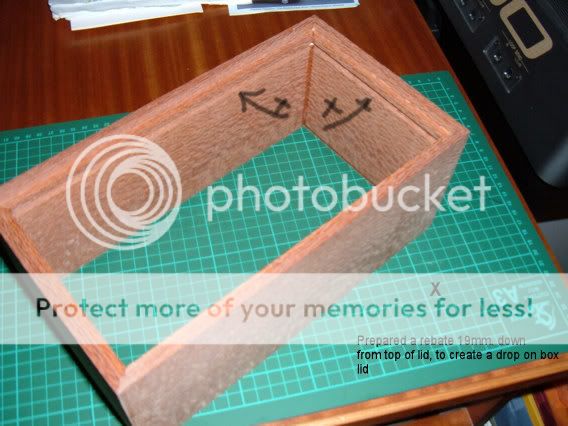

Picture showing rebates done on router.

A rebate on lip of lid. Not a dado

A rebate in preparation for drop on lid (a dado)

A rebate to insert base (not a dado)

Box glued up and ready for a veneered lid to be inserted. ( the base will be inserted when lid cut off at a later time.

The tablesaw will cut into the box 6mm deep from the front sides just below the dado created inside. Hopefully the cuts will line up and the lid will then drop down on to the lower box section.

This time I intend to have a drop down lid which has had rebates prepared prior to cutting off the lid from the bottom portion of the box.

Freehand sketch below, I have not seen a box prepared previously in this manner but other members might tell me it is old hat. ..

Picture of the 36” x 4 ½” 12mm prepared lacewood.

Picture showing rebates done on router.

A rebate on lip of lid. Not a dado

A rebate in preparation for drop on lid (a dado)

A rebate to insert base (not a dado)

Box glued up and ready for a veneered lid to be inserted. ( the base will be inserted when lid cut off at a later time.

The tablesaw will cut into the box 6mm deep from the front sides just below the dado created inside. Hopefully the cuts will line up and the lid will then drop down on to the lower box section.