devonwoody

Established Member

Decided to give the strip design boxes a rest this time, partly because I purchased a new stock of hardwood in the week.

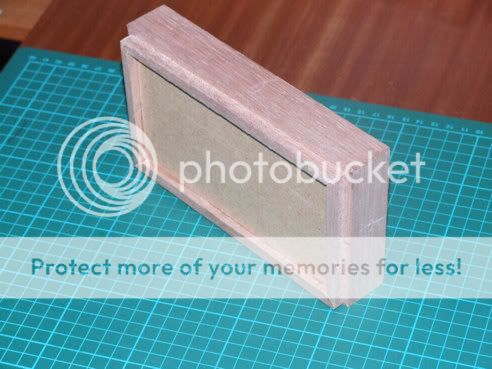

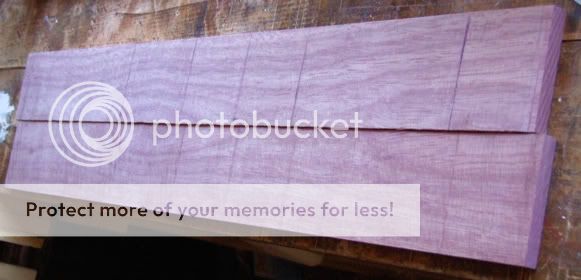

So making a box using purple heart and having in mind keeping the design of the box close to the Golden proportions.

So length is 204mmx 136widex 68 high..

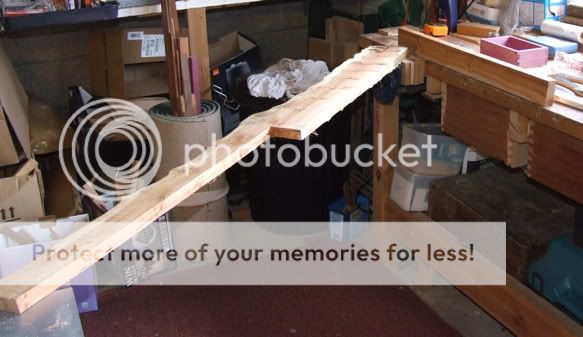

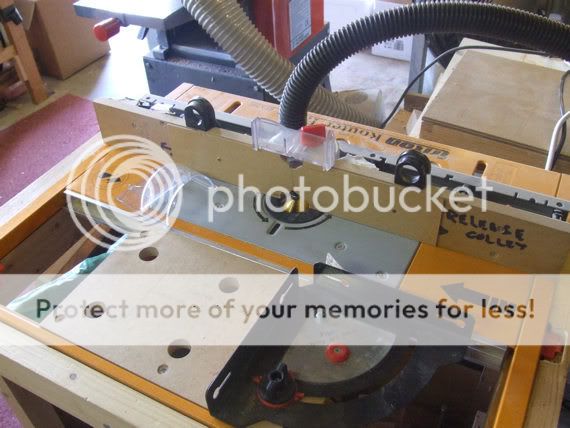

Prepared a short length of P/H on the bandsaw which was 25.4 mm thick and finished with two halves 11.2 & 10.4 after putting through the thicknesser, which means I only lost 3.8mm overall using both machines.

I did look at a new bandsaw machine earlier in the week but I was dissatisfied with the fence that came with the saw. My present saw rpsb12 has a fence which is very adaptable and will track to the blade perfectly if I am prepared to be diligent in its set up.

Then cut the timber to lengths on my chop saw and finished up with only that short piece of wastage. Also I have one length of 700mm left from the resaw for another day.

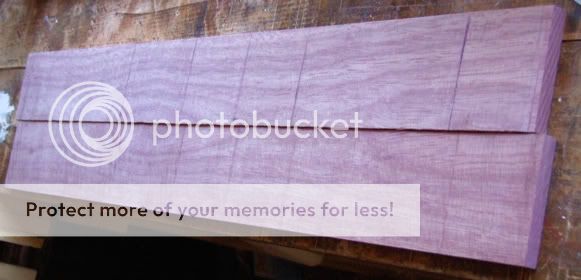

Couldn't resist putting the purple heart on that orange tabletop!

So making a box using purple heart and having in mind keeping the design of the box close to the Golden proportions.

So length is 204mmx 136widex 68 high..

Prepared a short length of P/H on the bandsaw which was 25.4 mm thick and finished with two halves 11.2 & 10.4 after putting through the thicknesser, which means I only lost 3.8mm overall using both machines.

I did look at a new bandsaw machine earlier in the week but I was dissatisfied with the fence that came with the saw. My present saw rpsb12 has a fence which is very adaptable and will track to the blade perfectly if I am prepared to be diligent in its set up.

Then cut the timber to lengths on my chop saw and finished up with only that short piece of wastage. Also I have one length of 700mm left from the resaw for another day.

Couldn't resist putting the purple heart on that orange tabletop!