Modernist

Established Member

I needed to tidy up the nav station and install a new plotter on my boat and a few problems arose when measuring up.

This was the situation at the outset.

Several of the old radio's etc were redundant and the panel needed refurbishing before re-installing the good stuff

The plotter needed a binnacle over the chart table

The chart table lid would not be able to open under the binnacle so would need a second piano hinge and the fiddle mitreing back to allow it to open and give it a stop.

I started with the easy one the piano hinge in the lid.

Remembering to maintain the overall depth so that the trim lined up I sawed to top in two and created a 5mm gap for the hinge. I cut back the fiddles to 45 deg to act as a stop.

Luckily I found that the original had been varnished in Sikkens Marine Natural which matched perfectly (that's this year's good luck used up already)

Next the casing for the plotter

Although the boat is Mahogany I decided to use some nicely figured Sapele which I was re-cycling from an old staircase.

The usual saw and surface routine produced some nice timber (and free)

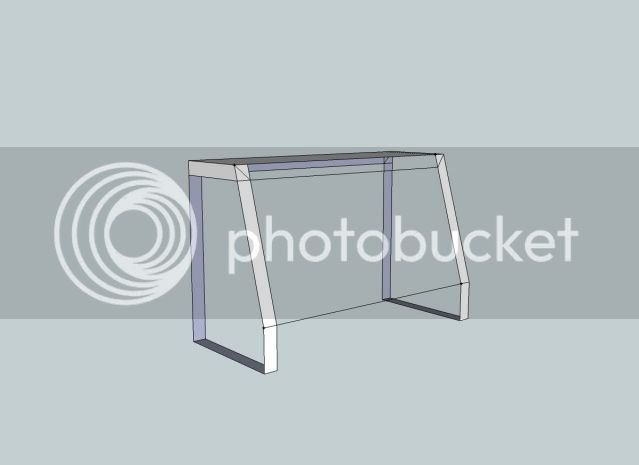

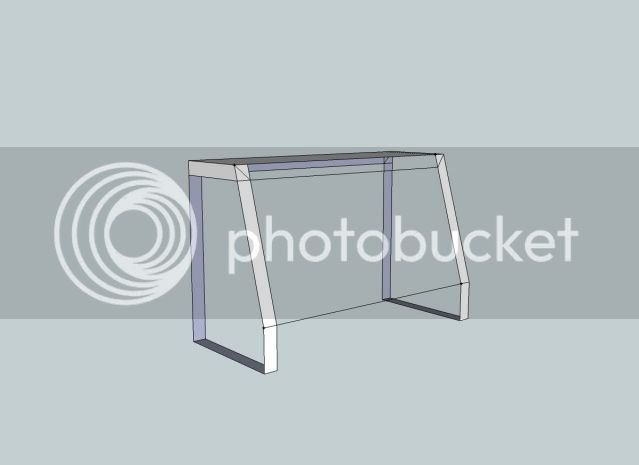

I did a rough sketchup to work out the size of the sides to give the required viewing angle

I needed a pencil tray on the top which would hang onto the pencils whilst at sea and decided to build up mouldings on top of a 10mm base.

The top would be mitred and domino'd to the sides but the base was a little thin at 10mm so I would have to cut the doms down and restrict the plunge on the cutter. I had made a small upgrade to the mitre shooting board since last week and glued the 45 deg offcut to the bottom edge to prevent wear.

I dom'd up a simple frame for the base as I wanted to leave the base and back open for maintenance.

This was my first serious job with the domino and I must say I was impressed with the speed you can knock things out. Just as well when you consider the price. The glue up went to plan and we had a carcass!

I made a front panel of off white MFC and made sure the plotter would fit before proceeding

At this point LOML arrived and said she wasn't having white chip board at any price so I had to think again. :evil: I had a piece of 8mm Sapele 120mm wide which I decided to deep cut and saw veneer a panel to maintain the appearance. I risked putting a piece of MFC through the thicknesser to mill it down to 15mm and it seems to have survived.

As luck would have it I had just bought a new vac bag and valve and had got over the extortionate charge so out came the Airpress for the first time in a while

It cleaned up well having struggled to work out which way the grain was going I was lucky again

And in went the veneered panel

Another dry run - seems OK

Just the clean up and finishing tomorrow.

Inspired by the success of the sawn veneer I decided to make up a new part panel to let into the instrument panel keeping the outer frame and had some re-cycled Honduras Mahogany salvaged from a Midland Bank. This was a bit of a test for the bandsaw cutting 3mm veneers from 250mm material but, in the event, it was problem free.

A solid post from the salvage - this was going to be burnt!

Deep sawing the 250mm stock

IN the airbag Mahog both sides of some awful FE ply

I think that's enough for one day! I'm ready for a beer.

This was the situation at the outset.

Several of the old radio's etc were redundant and the panel needed refurbishing before re-installing the good stuff

The plotter needed a binnacle over the chart table

The chart table lid would not be able to open under the binnacle so would need a second piano hinge and the fiddle mitreing back to allow it to open and give it a stop.

I started with the easy one the piano hinge in the lid.

Remembering to maintain the overall depth so that the trim lined up I sawed to top in two and created a 5mm gap for the hinge. I cut back the fiddles to 45 deg to act as a stop.

Luckily I found that the original had been varnished in Sikkens Marine Natural which matched perfectly (that's this year's good luck used up already)

Next the casing for the plotter

Although the boat is Mahogany I decided to use some nicely figured Sapele which I was re-cycling from an old staircase.

The usual saw and surface routine produced some nice timber (and free)

I did a rough sketchup to work out the size of the sides to give the required viewing angle

I needed a pencil tray on the top which would hang onto the pencils whilst at sea and decided to build up mouldings on top of a 10mm base.

The top would be mitred and domino'd to the sides but the base was a little thin at 10mm so I would have to cut the doms down and restrict the plunge on the cutter. I had made a small upgrade to the mitre shooting board since last week and glued the 45 deg offcut to the bottom edge to prevent wear.

I dom'd up a simple frame for the base as I wanted to leave the base and back open for maintenance.

This was my first serious job with the domino and I must say I was impressed with the speed you can knock things out. Just as well when you consider the price. The glue up went to plan and we had a carcass!

I made a front panel of off white MFC and made sure the plotter would fit before proceeding

At this point LOML arrived and said she wasn't having white chip board at any price so I had to think again. :evil: I had a piece of 8mm Sapele 120mm wide which I decided to deep cut and saw veneer a panel to maintain the appearance. I risked putting a piece of MFC through the thicknesser to mill it down to 15mm and it seems to have survived.

As luck would have it I had just bought a new vac bag and valve and had got over the extortionate charge so out came the Airpress for the first time in a while

It cleaned up well having struggled to work out which way the grain was going I was lucky again

And in went the veneered panel

Another dry run - seems OK

Just the clean up and finishing tomorrow.

Inspired by the success of the sawn veneer I decided to make up a new part panel to let into the instrument panel keeping the outer frame and had some re-cycled Honduras Mahogany salvaged from a Midland Bank. This was a bit of a test for the bandsaw cutting 3mm veneers from 250mm material but, in the event, it was problem free.

A solid post from the salvage - this was going to be burnt!

Deep sawing the 250mm stock

IN the airbag Mahog both sides of some awful FE ply

I think that's enough for one day! I'm ready for a beer.