devonwoody

Established Member

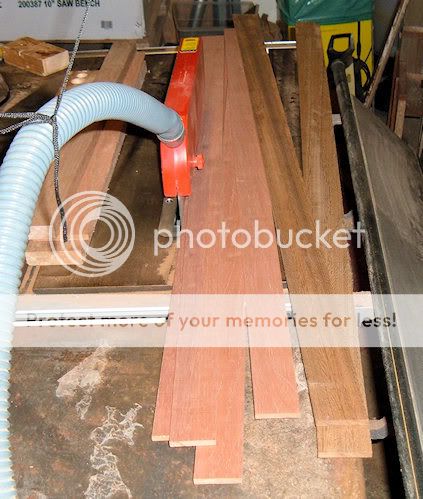

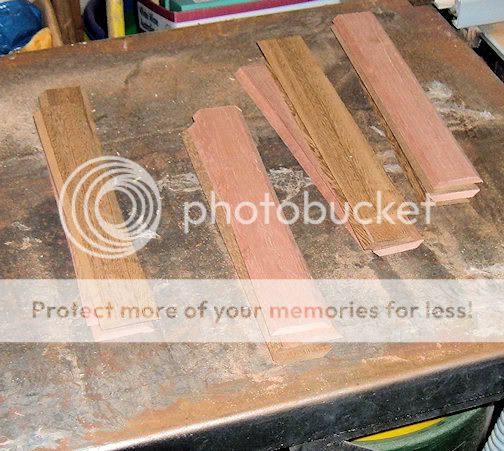

Started preparing timber for 6 pen tidies, getting ready for Xmas.

OPJ":n6poc5m4 said:You seem to be very busy at the moment, DW!

kevin":x46y3f00 said:OPJ":x46y3f00 said:You seem to be very busy at the moment, DW!

Exactly, what you on D.W. i need some. :lol:

devonwoody":3cu42e8o said:(Around 1000 bulbs to plant)

devonwoody":gk1j5pwn said:The reason being that the second timber choice for the other two boxes were going to be in Oak, but there is a timber flaw, shake?.

devonwoody":1kezs7ju said:One of my friendly neighbours popped into my shed yesterday and she was lucky, she got a promise of a box.

Enter your email address to join: