devonwoody

Established Member

Friends and family have been hinting they would like a box and to be honest I am running out of display space at home so I am pleased that I have somewhere to put new boxes.

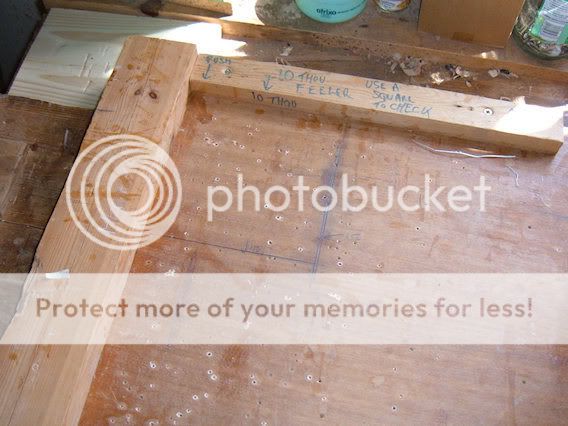

I have a piece of American Ash 27” x206mm x54mm with some nice grain and this should make 6 boxes six inches square but there is a nasty flaw at one end so I might only obtain 5 boxes of that size at the end of the day. They need to be 6 inches square because the internal dimension will take a DVD disk in its cardboard package.

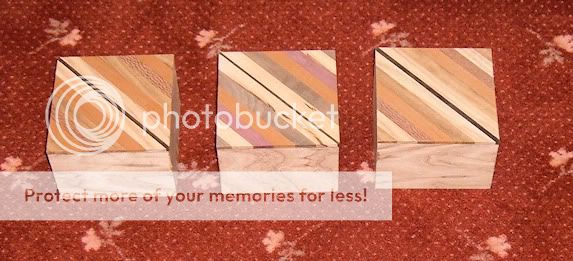

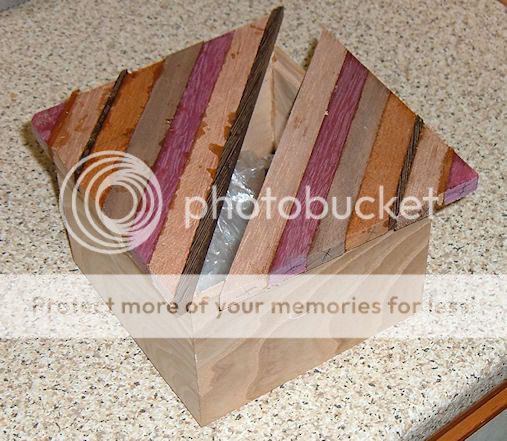

So I am aiming to mass produce a copy of this box I did earlier this year.

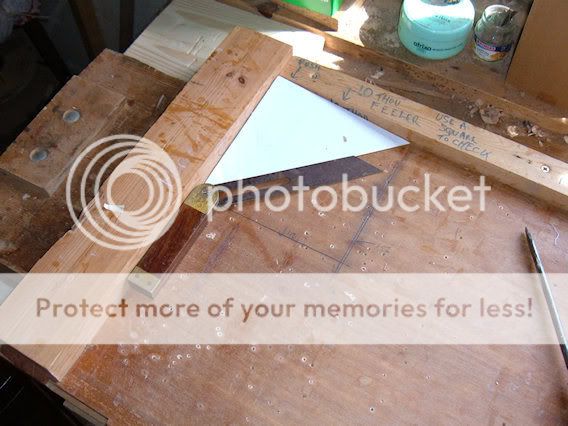

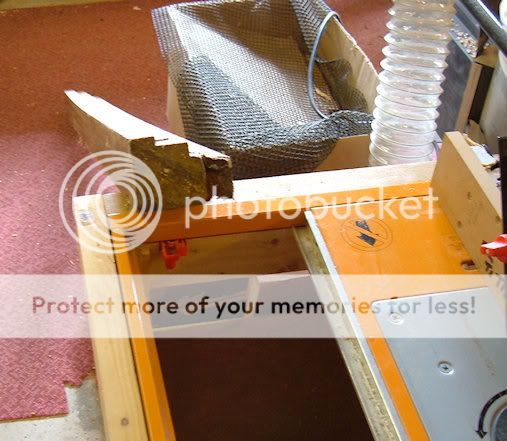

This is the area which has a bad patch.

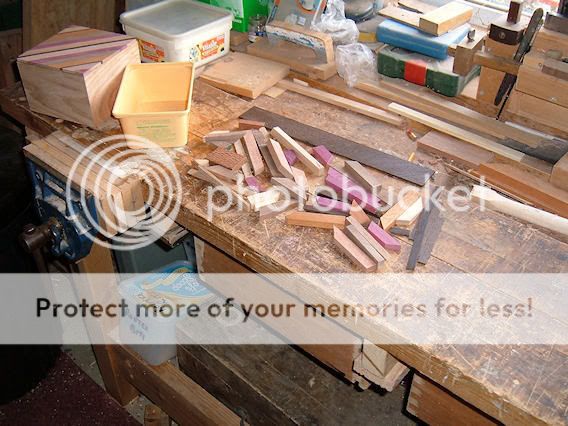

Put face edges on one side and edge then took over to the tablesaw and obtained two lengths 100 mm wide.

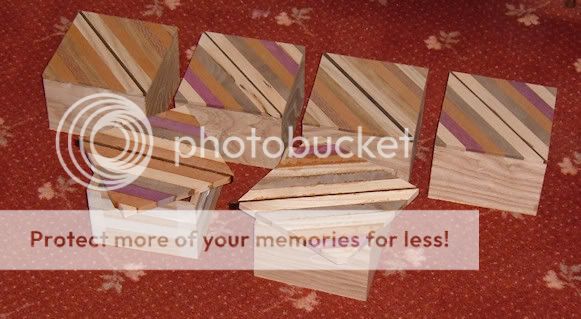

Each large piece was then run past the bandsaw and I go 6 perfect pieces 16mm thick, these were then cleaned up on the thicknesser and reduced to just over 11mm final thickness each.

At the end of the day I had machined rebates on both edges of all pieces (ready for future use has lid and base fittings.) and stacked up with some weights to hopefully stop any pieces floating up or bowing over the next 48 hours when I hope to restart.

I have a piece of American Ash 27” x206mm x54mm with some nice grain and this should make 6 boxes six inches square but there is a nasty flaw at one end so I might only obtain 5 boxes of that size at the end of the day. They need to be 6 inches square because the internal dimension will take a DVD disk in its cardboard package.

So I am aiming to mass produce a copy of this box I did earlier this year.

This is the area which has a bad patch.

Put face edges on one side and edge then took over to the tablesaw and obtained two lengths 100 mm wide.

Each large piece was then run past the bandsaw and I go 6 perfect pieces 16mm thick, these were then cleaned up on the thicknesser and reduced to just over 11mm final thickness each.

At the end of the day I had machined rebates on both edges of all pieces (ready for future use has lid and base fittings.) and stacked up with some weights to hopefully stop any pieces floating up or bowing over the next 48 hours when I hope to restart.