We have 2 side windows in a gable end which will be difficult to reach after an extension is built. They are 30 yrs old and rotting - not badly - but never-the-less the time to replace them is now rather than when they are difficult to reach.

They are each single sash windows, 1180mm x 490 mm, hinged down the RHS as you look out from the inside. They will need to be on easyclean egress friction hinges because it will be difficult to reach them from outside, and the current windows which are simple casements suffer from flies gathering in the gaps around the edge which then cascade into the room when the window is opened. I therefore plan to replace them with European Oak storm proof sashes with a 5mm Silplex bubble bead between the overlap and the frame to prevent flies getting in to the gap, and with the back of the sash sitting on an Aquamac 63 seal. Locks will be high security shoot bolts.

I am planning to use the same laminated construction method as I've just used on my back door, partly because I'm familiar with it, and partly because this will have to be done on a router table as I have no spindle.

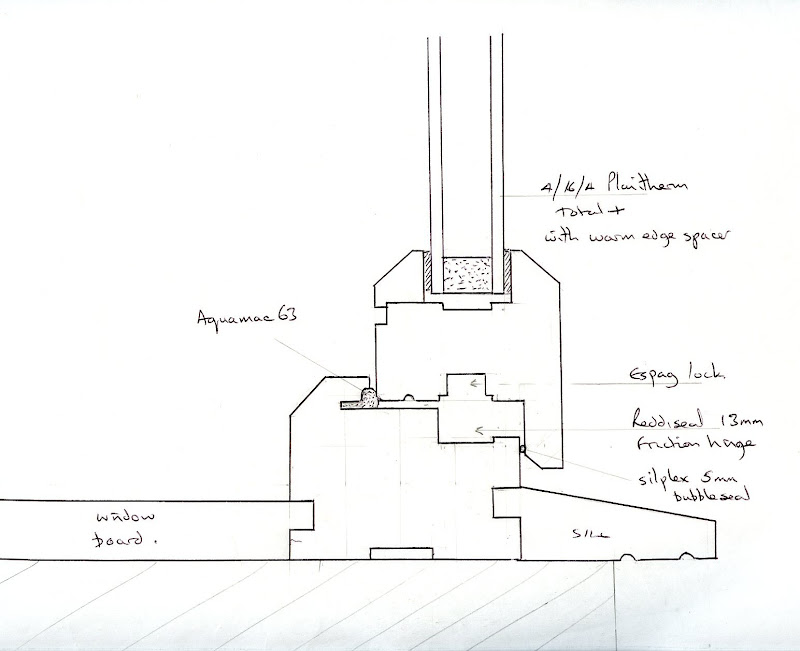

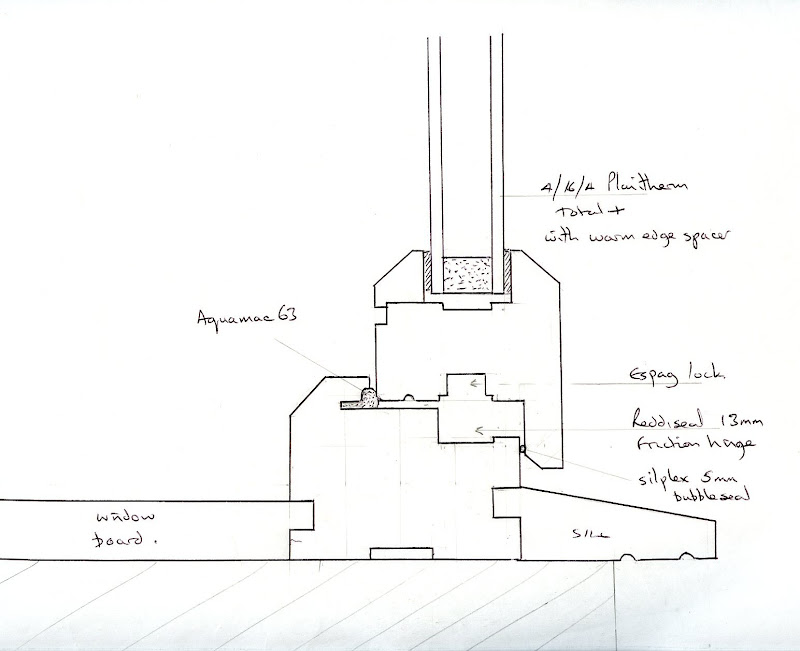

Here's the section I thought I'd use.

Any constructive comments please from those who have experience in this field?

The glazing will be Planitherm Total+ 4/16/4 set with a warm edge spacer, and which should give a U value of 1.1. We rely on this side winmdow a lot for morning light (it's east facing) so want to keep the section width to a minimum, although thickness isn't an issue. The drawing as shown provides for a thickness (inside to outside) of 75mm, and a frame width (wall to sash) of 60mm (max) along the bottom, and 45mm up the sides and along the top. Glazed unit will be installed from the inside for security and also for ease of weather proofing.

What's the current thinking on trickle vents. I've been looking at windows in showrooms and there is not a trickle vent to be seen anywhere. My own view is that if we don't have to have them, then let's not.

They are each single sash windows, 1180mm x 490 mm, hinged down the RHS as you look out from the inside. They will need to be on easyclean egress friction hinges because it will be difficult to reach them from outside, and the current windows which are simple casements suffer from flies gathering in the gaps around the edge which then cascade into the room when the window is opened. I therefore plan to replace them with European Oak storm proof sashes with a 5mm Silplex bubble bead between the overlap and the frame to prevent flies getting in to the gap, and with the back of the sash sitting on an Aquamac 63 seal. Locks will be high security shoot bolts.

I am planning to use the same laminated construction method as I've just used on my back door, partly because I'm familiar with it, and partly because this will have to be done on a router table as I have no spindle.

Here's the section I thought I'd use.

Any constructive comments please from those who have experience in this field?

The glazing will be Planitherm Total+ 4/16/4 set with a warm edge spacer, and which should give a U value of 1.1. We rely on this side winmdow a lot for morning light (it's east facing) so want to keep the section width to a minimum, although thickness isn't an issue. The drawing as shown provides for a thickness (inside to outside) of 75mm, and a frame width (wall to sash) of 60mm (max) along the bottom, and 45mm up the sides and along the top. Glazed unit will be installed from the inside for security and also for ease of weather proofing.

What's the current thinking on trickle vents. I've been looking at windows in showrooms and there is not a trickle vent to be seen anywhere. My own view is that if we don't have to have them, then let's not.