Scouse

Established Member

I picked this WS 5 1/2 up on ebay a couple of months ago. I'd been looking for a 5 1/2 for a while, but they seemed to have become trendy and the prices put me off, so grabbing this one cheap was a bonus. It was in a sorry state, not quite a basket case, but very rusty...

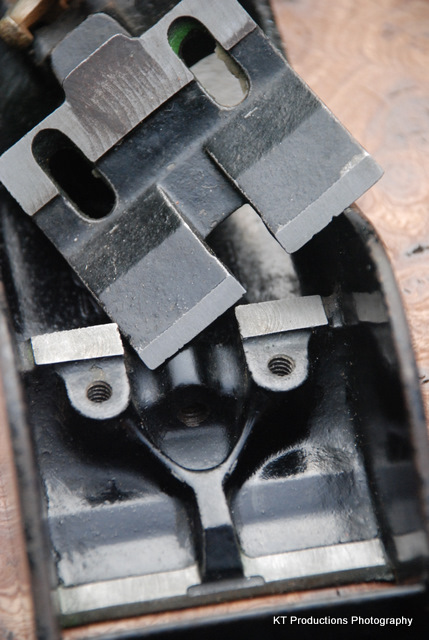

First, getting it into bits

Just loads of dirt and rust, so into an electric bath she goes. I know there are as many rust removal techniques as there are ways to sharpen a blade, but electrolysis works best for me, a small initial outlay and near zero running costs. It is a bit of a faff to set up though, so not worth it unless you have a few bits to do.

Anyway, the body, blade and cap iron where electrolysised (???) and the lever cap liberally beaten with a Brasso soaked rag and this emerged from the gloom...

The lever cap went from this

To this

and the plane to this

It is a sympathetic restoration, no need to strip and repaint or mess with the wood, but it feels good to put it back to work.

A V&B 4 1/2 and a narrow Stanley 5 1/2 are undergoing the same treatment, I'll post the results later this week, but I think the V&B will need paint of some description.

El.

First, getting it into bits

Just loads of dirt and rust, so into an electric bath she goes. I know there are as many rust removal techniques as there are ways to sharpen a blade, but electrolysis works best for me, a small initial outlay and near zero running costs. It is a bit of a faff to set up though, so not worth it unless you have a few bits to do.

Anyway, the body, blade and cap iron where electrolysised (???) and the lever cap liberally beaten with a Brasso soaked rag and this emerged from the gloom...

The lever cap went from this

To this

and the plane to this

It is a sympathetic restoration, no need to strip and repaint or mess with the wood, but it feels good to put it back to work.

A V&B 4 1/2 and a narrow Stanley 5 1/2 are undergoing the same treatment, I'll post the results later this week, but I think the V&B will need paint of some description.

El.