Steve Maskery

Established Member

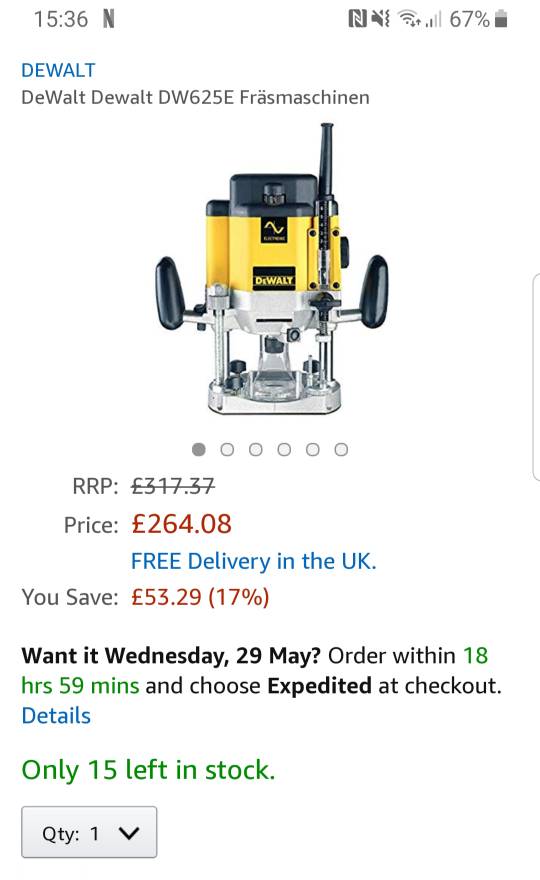

I have to make a very shallow groove on the edge of some MDF panels. I have to use a particular wing cutter, because it is a match for some tongued lipping I have made, and that cutter has a 1/2” shank. That in turn means I have to use my big router, but because I want only a shallow cut, most of the cutter has to be shrouded inside the aperture of the fence.

This router is big and heavy and a bit unweildy. The result is that the centre of gravity of the router is way off the edge of the board, most of the weight is unsupported and there is a huge tendency for the router to tip, which would seriously spoil my day.

The start and stop positions are even worse, there are just a few square centimetres of contact between the router base and the workpiece; it is very precarious indeed.

If I had only these relatively small panels to do, I could groove them on the Router Table, but I also have some 2.1m long panels to do and there is no way I can manhandle them on my own.

The traditional way to overcome this is to fix a teardrop-shape sub-base to the router, but that is not possible here, as the sub-base and fence would get in each other's way.

So I decided to make a stabilising foot to stop my router from tilting.

I started with a piece of 6mm MDF which just fits nicely between the fence rods, and this is then glued across the middle of the base of the foot. This will prevent the foot from twisting.

That base is 12mm thick, but the distance from the underside of the fence rods to the base is a little over that, so by sticking on a piece of plastic laminate I get the right thickness to make the foot and the router base level with each other, as well as a nice smooth-running surface.

This router is big and heavy and a bit unweildy. The result is that the centre of gravity of the router is way off the edge of the board, most of the weight is unsupported and there is a huge tendency for the router to tip, which would seriously spoil my day.

The start and stop positions are even worse, there are just a few square centimetres of contact between the router base and the workpiece; it is very precarious indeed.

If I had only these relatively small panels to do, I could groove them on the Router Table, but I also have some 2.1m long panels to do and there is no way I can manhandle them on my own.

The traditional way to overcome this is to fix a teardrop-shape sub-base to the router, but that is not possible here, as the sub-base and fence would get in each other's way.

So I decided to make a stabilising foot to stop my router from tilting.

I started with a piece of 6mm MDF which just fits nicely between the fence rods, and this is then glued across the middle of the base of the foot. This will prevent the foot from twisting.

That base is 12mm thick, but the distance from the underside of the fence rods to the base is a little over that, so by sticking on a piece of plastic laminate I get the right thickness to make the foot and the router base level with each other, as well as a nice smooth-running surface.