First of all...huge thanks again to Shane for the chance to have a look at this fine saw.

And fine it is..as in "fine art".

Before I begin my findings..I will emphasise that I am looking at this mostly from an aesthetic and ergonomic standpoint...I will leave other to review "making dovetails"...I am sure there are some in the list who are past masters at this! And I apologise for any repetition...but things repeated stay in the mind after all! :wink:

I've spoken with Shane at length...he has a true passion for his craft and the attention to detail is astounding.

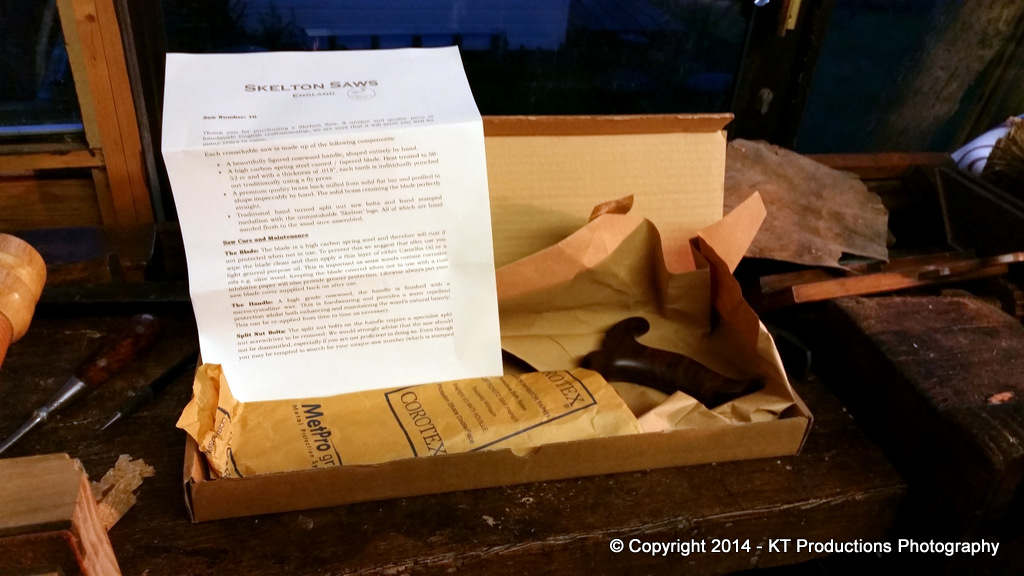

This extends to the packaging...which when you buy a boutique saw is sort of expected but often absent these days.

The spring steel plate needs to be protected as it can corrode easily and the saw comes wrapped in rust inhibiting paper..this is good as I keep most of my saws in the stuff and they're never even developed a spot..

Traditional saw making in England has all but disappeared so SKELTON SAWS are important on so many levels. Researchers of historically significant tools will be pleased to know that each saw is numbered..this is No.10 and further than that...the company keeps a record of each saw...along with a log of the owner. In a hundred years time when someone wants to go back through history..it will all be there...as I know the saw will be.

In use...balance is all important and care has been taken to ensure this saw is perfect in this respect. This is just one of a number of factors which makes the cutting of dovetails a breeze.

I will start right off by saying that I wanted to compare this saw with others..I have two candidates...my treasured saw "Ginger" from Klaus and Pedder...and another fine saw I have just acquired by W.Taylor...who Simon Barley lists but about which nothing appears to be known.

As expected both Ginger....

...and the SKELTON SAW...

...cut beautifully. It's not fair at all to compare two Rolls Royces...they are both sublime!

I am no cabinet maker nor jointer and I think I can count on the fingers of one hand how many dovetail joints I have done...so I have no intention of getting into a "my dovetail's better than yours" competition...I'll leave that up to the true experts..but I will show the results of the actual cuts...

Three cuts...TLT left...next to the SKELTON and then on the right...the old TAYLOR

Considering the Taylor is a few moons older and in dire need of seeing a dentist...it didn't do too badly but the other two were sublime...and as to be expected..nothing in it really...maybe the TLT is finer...but only by a gnat's whatsit!

I followed the tapered concept...level brass back to bench..cut to line..peer over and then cut back to line. This is something I think is of benefit to novices and experienced users alike...and makes sense...another "attention to history" moment.

So..some of the other "special things".

The back is solid..slot cut very accurately and then carefully cut into the handle by hand.

As we can see..the design of the handle is straight from the Georgian period...and like most things of that era..they reached the zenith of beauty and functionality...and SKELTON saws have obviously reproduced this faithfully...this I like a lot...as I love that period too.

Echoes of history are very evident...and this is something which attracts me. Modern interpretations of this style had been attempted by other makers over the generations and sadly...nothing comes close to the class of this shape.

The plate fits seamlessly into the slot in the brass back...with the company logo boldly emblazoned on its side...a mark hand stamped using a press and one of CHALCO STAMP AND DIE's wonderful punches...I just knew this the moment I saw it!

The teeth are beautiful. They are hand cut using a purpose-made die..individually and then hand sharpened and set. I know of one other maker that goes to these lengths to achieve perfection....I have one such saw! :wink:

For the technical buffs..here is the full specification:

Handle: Selected Indian rosewood...plantation grown.

Cut: Rip

Rake: 8 degrees

Plate type: Selected spring steel tapered cut.

Plate thickness: 18 thou.

Set: 2-3 thou.

Teeth: 15 TPI (16 PPI)

Finishing touches include the saw medallion...not a random "Warranted" gooble-de-**** but justifiable pride.

The engraved design is based on the SKELTON of YORKSHIRE family shield...a peacock carrying an oak branch and acorn in its mouth and the SKELTON family name. This is a nice touch historically but also it stands alone to emphasise all the other bespoke elements which may not be fully appreciated on first inspection. The "Spirit of Ecstasy" on this fine saw.

So...in conclusion..the acid test...would I buy one...well no...because I already have a fine dovetail saw...

But I do need to take longer than a couple of days to make absolutely sure that I like it...so I shall be sending a hand print off to Shane so he's ready when he makes a carcass saw... :mrgreen: :mrgreen:

Recent appreciation for the use of hand tools has been exponential and we were that close to not being able to compete in that market...here and overseas.

Mr Skelton has allowed me to breath a huge sigh of relief because with this saw...we are very much in the running again in Britain...which is just as it should be!

Cheers

Jimi