CHJ

Established Member

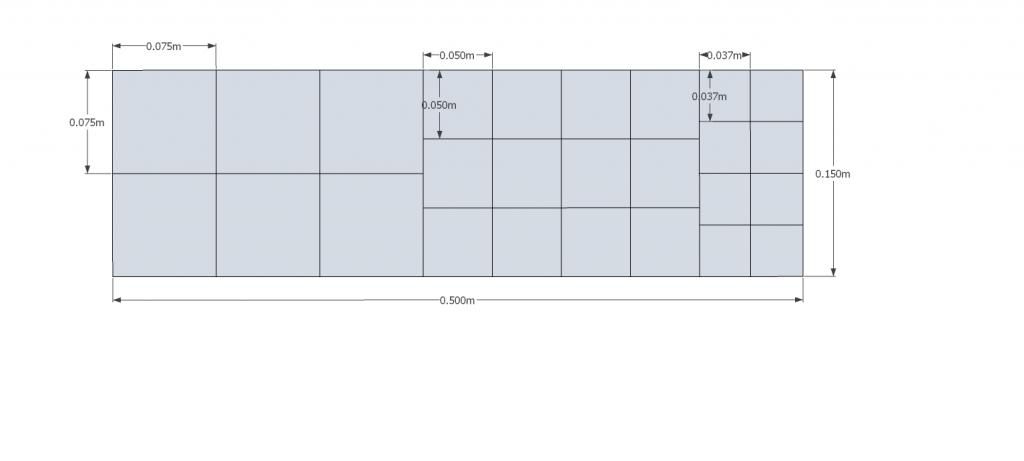

Being a one for watching the pennies I cut my nominal 50mm pads from sheet stock.

Having spent half hour this afternoon sorting some of the spare stock I thought folks might be interested in how I make sure I don't skew cut and end up with that remaining strip that's just a tad small for the pad.

Always one to measure once and for all and make a simple jig, I made up a simple marking sheet out of a bit of Plexiglas.

To do similar with Plexiglas or Ply mark out your sample abrasive and use this to drill a series of small pencil guide holes in the template.

Use the template to spot through to new sheet with a pencil.

If you want, join the dots.

I store my template in the abrasives bin.

The front lift out flap just stops too much debris finding its way in, it's close to the headstock.

Having spent half hour this afternoon sorting some of the spare stock I thought folks might be interested in how I make sure I don't skew cut and end up with that remaining strip that's just a tad small for the pad.

Always one to measure once and for all and make a simple jig, I made up a simple marking sheet out of a bit of Plexiglas.

To do similar with Plexiglas or Ply mark out your sample abrasive and use this to drill a series of small pencil guide holes in the template.

Use the template to spot through to new sheet with a pencil.

If you want, join the dots.

I store my template in the abrasives bin.

The front lift out flap just stops too much debris finding its way in, it's close to the headstock.