jimi43

Established Member

Oh dear...what am I thinking of....

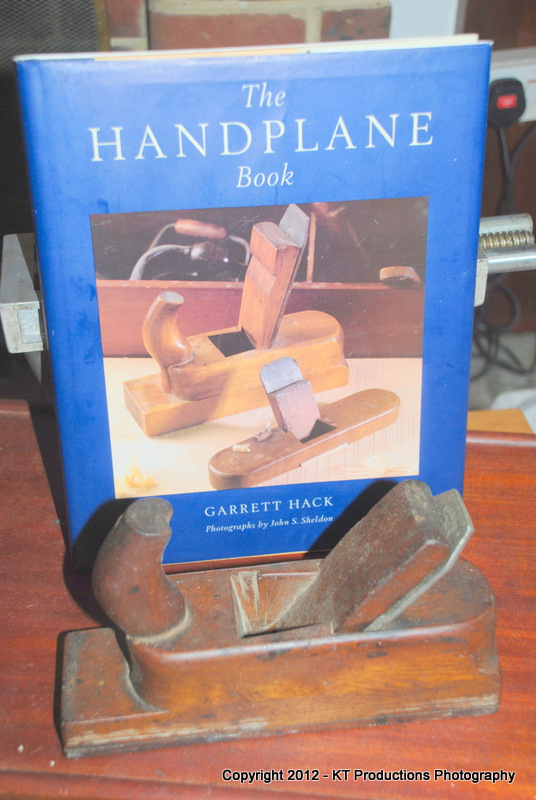

The bootfair today was a virtually rained off nightmare but I had to leave with this little teutonic beauty.

The horn needs regluing...

...the iron needs some major surgery....

...to remove light rust! :mrgreen:

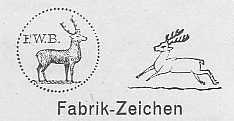

...but I know the iron maker at least....

It is "resting" in Corro-Dip at the moment...for the next 24 hours at least...so once I get the iron shaving I will be able to post some comments about performance....but at the moment...

...I can just sit and admire it....I don't normally like these European planes but this one works for me on so many levels and I have a feeling it's a bit "special"....we shall see.

Guten abend! :wink:

Jim

The bootfair today was a virtually rained off nightmare but I had to leave with this little teutonic beauty.

The horn needs regluing...

...the iron needs some major surgery....

...to remove light rust! :mrgreen:

...but I know the iron maker at least....

It is "resting" in Corro-Dip at the moment...for the next 24 hours at least...so once I get the iron shaving I will be able to post some comments about performance....but at the moment...

...I can just sit and admire it....I don't normally like these European planes but this one works for me on so many levels and I have a feeling it's a bit "special"....we shall see.

Guten abend! :wink:

Jim