beech1948

Established Member

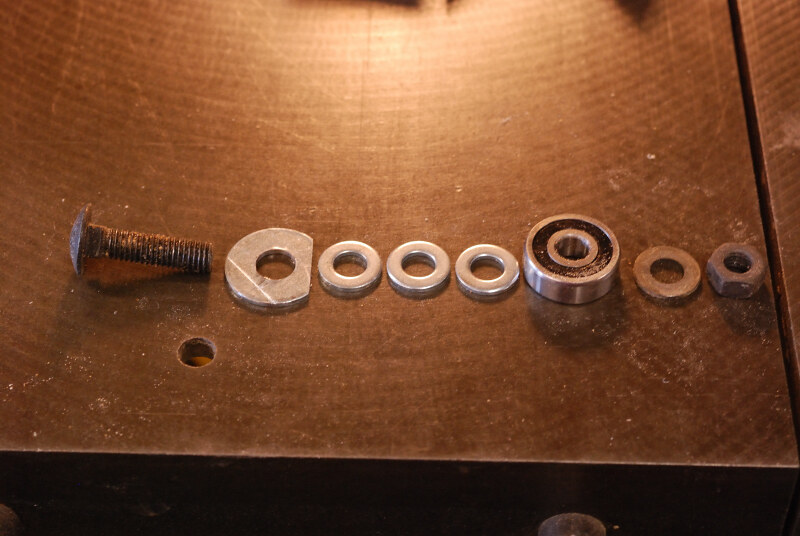

Oh!. ALT Saws and I discussed the provision by them of a bearing based set up. They could do it and came back with a quote and a list of parts ( God only knows where that is now). I did not go with them at that time because they seemed to vanish in front of my eyes and became somewhat unresponsive.

You may get different mileage.

Alan

You may get different mileage.

Alan