I have a JetMac 2hp dust collector with either a nvr or magnetic switch. I bought a remote control socket receiver and remote control. Bascially plug DC in and turn it on and off. Bit the current setup is that Everytime the machine powers off I cannot turn back on with remote. I had an electrician rewire it to a normal on/off tool switxh but her never did anything like that and it worked but after about 20 minutes motor failed. Jetmac replaced entire motor and switch. I would like to know if there is a way I can do this. My remote can power three items and I want to hook the 2hp Dc, and my in shop wet/dry vac to it. Will attach photos if can

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help pls with Dust collector

- Thread starter Rmo67

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Myfordman

AKA 9Fingers

It is possible but it will bypass one possibly two safety systems designed into the product and so I feel I should not publicly publish how.

I can appreciate it that. However 100's of people change over there 2ho DC to such a thing. This is not a tablesaw nor something thst if power came back in could hurt you. This unit is situated outside my workshop 8 feet up on the wall. So I have to go out Everytime and turn on n off whenever making a cut, sanding etc. Far more unsafe is that at times a person is less likely to do such a thing and just use those other machines for a min or two with no dust collection

Myfordman

AKA 9Fingers

OK

Click on my username and the envelope symbol in my profile to email me directly and I will send you a diagram to follow. It might take me a day or so to draw it.

As a new member you "might" need one more post to the forum before you can see the icon for email. Just reply to this post and you should have enough.

Click on my username and the envelope symbol in my profile to email me directly and I will send you a diagram to follow. It might take me a day or so to draw it.

As a new member you "might" need one more post to the forum before you can see the icon for email. Just reply to this post and you should have enough.

If anyone else will use the machines, youre opening yourself up to many legal and financial problems if there is ANY kind of accident, because you have over ridden a safety device that the manufacturers were forced to install.

Having said that, There is a way to achieve what you want to do. I dont know if myfordman will give you the same advice, but my way keeps the NVR switch in use and so is completely safe in the event of loss of power and does not infringe any safety needs.

All that is needed is to find the live feed from the green button side of the NVR switch to the motor. Cut the live feed here. use two wires and run them both to somewhere convenient for you. Wire them into your remote controlled socket.

Join the two wires back at the machine to make a loop to the motor.

Now, the NVR works in the normal way, but once you have energised the NVR switch, the live feed goes to the remote switch, and then back to the motor, so that the motor only operates when the remote switch is operated.

At the end of the working day, just press the red button on the NVR as normal.

Important note. Those two new wires will BOTH be live and should be brown wires. but if you use a twin core cable, the blue wire ends should be wrapped with red tape, to indicate to anyone who removes the cover that they are both live.

Having said that, There is a way to achieve what you want to do. I dont know if myfordman will give you the same advice, but my way keeps the NVR switch in use and so is completely safe in the event of loss of power and does not infringe any safety needs.

All that is needed is to find the live feed from the green button side of the NVR switch to the motor. Cut the live feed here. use two wires and run them both to somewhere convenient for you. Wire them into your remote controlled socket.

Join the two wires back at the machine to make a loop to the motor.

Now, the NVR works in the normal way, but once you have energised the NVR switch, the live feed goes to the remote switch, and then back to the motor, so that the motor only operates when the remote switch is operated.

At the end of the working day, just press the red button on the NVR as normal.

Important note. Those two new wires will BOTH be live and should be brown wires. but if you use a twin core cable, the blue wire ends should be wrapped with red tape, to indicate to anyone who removes the cover that they are both live.

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£10.19 (£0.39 / count)

£11.99 (£0.46 / count)

Nicpro Carpenter Pencil with Sharpener, Mechanical Carpenter Pencils Set with 26 Refills, Case, Deep Hole Marker Construction Pencils Heavy Duty Woodworking Pencils for Architect (Black, Red)

NicproShop EU

£15.99 (£1.60 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£199.00

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£16.99

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£10.10

£15.48

Portwest Browguard with Clear Visor, Size: One Size, Colour: Clear, PW91CLR

Amazon.co.uk

Myfordman

AKA 9Fingers

Not correct on two counts SunnyBob

The remote socket will require a neutral and the live from the nvr to power it up and will also need the switched live back to the motor from the output socket on the front of the remote socket. Ideally should have an earth too but this is probably not connected.

Secondly the relay in the remote socket is not capable of handling the inrush current of a 2hp motor and will liklely fail early.

The remote socket will require a neutral and the live from the nvr to power it up and will also need the switched live back to the motor from the output socket on the front of the remote socket. Ideally should have an earth too but this is probably not connected.

Secondly the relay in the remote socket is not capable of handling the inrush current of a 2hp motor and will liklely fail early.

agreed on the operating power to the socket, I assumed too much thinking that was given.

I had not realised it was a 2 hp motor though, he would need a remote system capable of that.

The system is still sound, it just needs beefing up unless a relay was installed at the motor to allow a smaller operating circuit, but then it starts getting complicated.

I had not realised it was a 2 hp motor though, he would need a remote system capable of that.

The system is still sound, it just needs beefing up unless a relay was installed at the motor to allow a smaller operating circuit, but then it starts getting complicated.

user22161

Established Member

sunnybob":3oj18n8r said:If anyone else will use the machines, youre opening yourself up to many legal and financial problems if there is ANY kind of accident, because you have over ridden a safety device that the manufacturers were forced to install.

Most, if not all, of the remote switches are NVR themselves. If power is cut, it doesn't power the machine when it comes back on again, without pressing the button.

Trainee neophyte

Established Member

[youtube]QBc2G8OgsTo[/youtube]

What do you think?

What do you think?

SkinnyB

Established Member

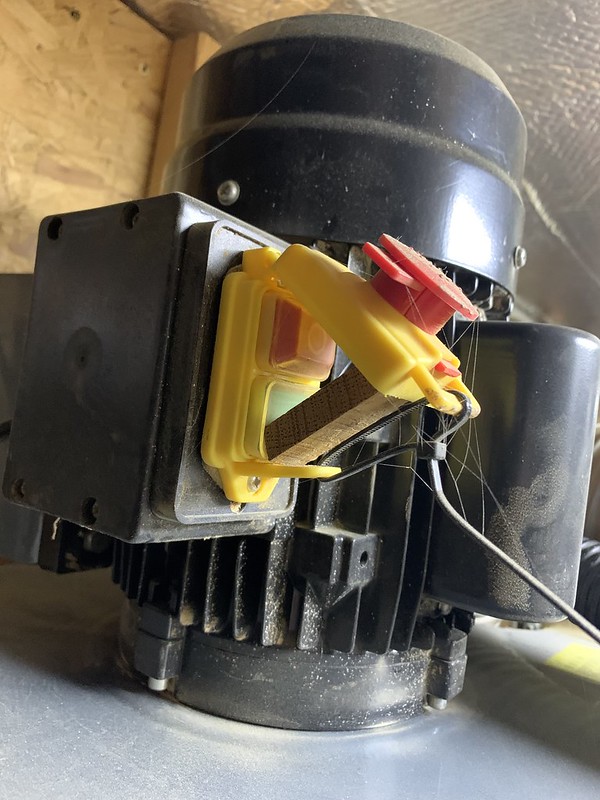

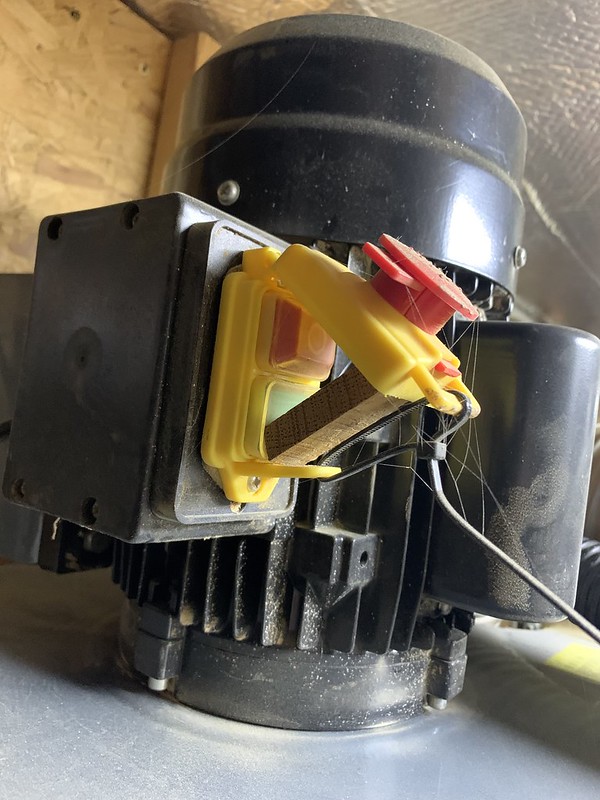

Rate my setup...

Bit of oak and cable tie hold the button down. Then operated via remote switch. Simple...

13amp remote socket. 3 years no issues.

IMG_0229 by jamie skinner, on Flickr

IMG_0229 by jamie skinner, on Flickr

IMG_8239 by jamie skinner, on Flickr

IMG_8239 by jamie skinner, on Flickr

Bit of oak and cable tie hold the button down. Then operated via remote switch. Simple...

13amp remote socket. 3 years no issues.

IMG_0229 by jamie skinner, on Flickr

IMG_0229 by jamie skinner, on Flickr IMG_8239 by jamie skinner, on Flickr

IMG_8239 by jamie skinner, on FlickrThe remote socket I have is exactly that when power cuts off there is no power to remote when it comes back on. Need to manually turn it on. As for safety. Again this is a dust collector. Motor/fan/blower is mounted outside about 8 feet high blocked by a caged unit to prevent water on it. Then connects to a cyclone which then enters my workshop thought wall by PVC pipes. Only people in my home are me and my wife and remotes are locked away when not in use. I was more concerned with people coming in my shop and turning something in while I was working so I worked hard on safety after getting a finger cut when I was working in a take saw unplugged (surprisingly this Makita did not have a safety switch) and a friend entered and plugged it in thinking it was the radio. Well only loss 2mm of top of middle finger and the nail. Since then everything has been refitted with saefty in mind. Regarding the DC: this is a typical unit with bags. So I installed a good cyclone that removed about all dust and I exhaust to the outside this allowing it a bit more power in suction and no need to change filter bag. An addition is noise reduction just like my air compressor sits outside and hose runs in on a mounted wheel. I did rewire the on/off to inside my shop.

Attachments

This actually worked heheheeSkinnyB":xanw0rx6 said:Rate my setup...

Bit of oak and cable tie hold the button down. Then operated via remote switch. Simple...

13amp remote socket. 3 years no issues.

IMG_0229 by jamie skinner, on Flickr

IMG_8239 by jamie skinner, on Flickr

Myfordman

AKA 9Fingers

To everyone who asked for my diagram, these have been sent out and not one has been acknowledged.

I'll know not to bother next time.

I'll know not to bother next time.