Woodbloke66

Which jigs for the proedge do you think are appalling quality? In what respect?

Just curious

Ian

Which jigs for the proedge do you think are appalling quality? In what respect?

Just curious

Ian

Just a suggestion - he might have a lathe for all we know.The OP doesn't mention having a lathe Jacob and even if he did unless it has an outboard facility for the faceplate it's highly inconvenient IMO (from experience) to remove what you're turning and fit the damn thing to touch up a gouge. Different if you do have outboard or can make a disk sander from an old motor as I agree they can be effective.

.......

Reading the posts he made it would suggest not however as you say we don't know either way of course.Just a suggestion - he might have a lathe for all we know.

My disc is inboard so not much use when turning, but also has a table and is very useful for other woodwork, surprisingly precise - would do for picture frame mitre fine adjustment, small items, boxes etc.

I've bought some velcro for an 8" outboard ply disc sander for turning/sharpening haven't got around to it yet

I made a ply disc for my lathe, it warped and was useless. Something less likely to warp?Thank you all for your thoughts

I do have a lathe - no outboard spindle though, maybe Ill keep my cash in my pocket; a ply disk on a faceplate with velcro adhesive pad/sandpaper/ seems a good way and I could make a table to fit into the banjo.

Trial and error to get the angles about right? or a wooden slope/guide? sitting on the table?

Does this sound sensible?

cheers

Snip .... but I certainly wouldn't use it for my bench chisels ....... snip

Yep. it's called "freehand" and it was utterly normal until the modern sharpening craze kicked off......

Trial and error to get the angles about right?....

I should probably rephrase that Daniel and say that the only reason I would use it is when I needed to reshape the primary bevel, I would then hone the edge to suit my needs, this is in fact what I do whereas with turning tools the edge straight from the po-edge is excellent for the job in hand.Could I ask why not, Lons ?

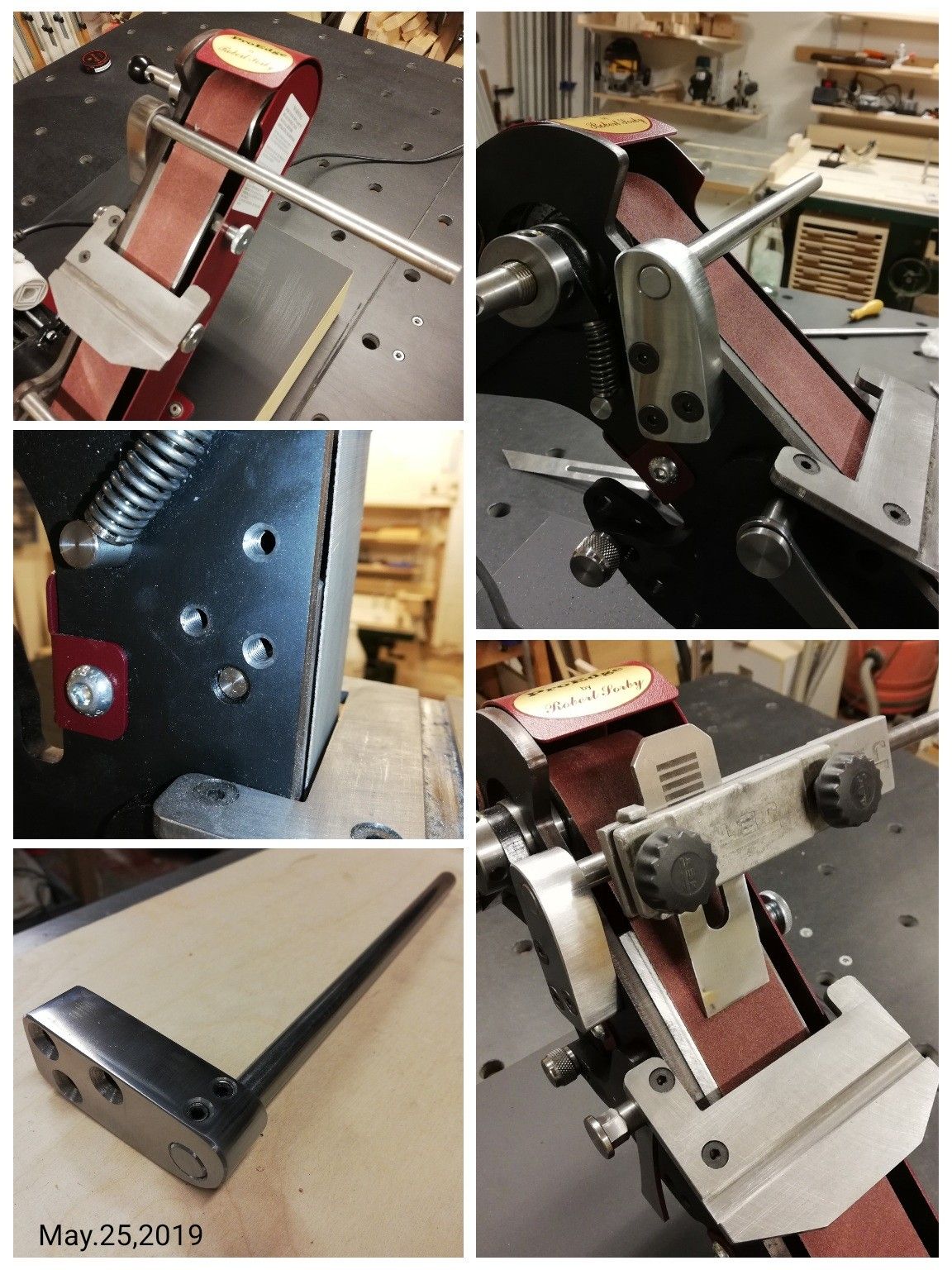

I'm seriously considering buying a ProEdge atm, but it's intended use would be, mainly,

bench chisels and plane irons.

Thicker ply. It'd need mounting on a face plate.I made a ply disc for my lathe, it warped and was useless. Something less likely to warp?

maybe, mine was 18mmThicker ply. It'd need mounting on a face plate.

okeydokey said:Trial and error to get the angles about right?....

Yep. it's called "freehand" and it was utterly normal until the modern sharpening craze kicked off.

I do have a lathe

Enter your email address to join: