scholar

Established Member

I have had a Jessem router table with Jessem Rout-r-Lift for some time. I have been very happy with it. I had my Trend T11 router installed and that worked fine, but I have always thought that it was unnecessary and wasteful to have all of the plunge capability of the router effectively going unused. I have from time to time looked for a simple router motor that I could fit to replace the T11. Recently I saw the Xact Router motor at a decent price with a 15% off offer from Rutlands – net price £127.46. So that is about £200 cheaper than the T11. Here is the motor I fitted http://www.rutlands.co.uk/sp+woodworkin ... or+rtx5003

This router motor seems to be sold under many different labels and I guess they are made in vast quantities in China - doesn't seem any the worse for that. It is powerful with input/output of 2400W/1800W which compares with the T11 that is no slouch at 2000W/1400W and a slightly higher max speed of 22,000rpm v 20,000rpm. On inspection, the collets (½” and ¼”) look rather cheap compared to the T11’s – retained in the collet nut by a circlip rather than the click in design on the T11, but I intend to fit a quick release chuck that makes for much easier cutter change in the router table.

Otherwise it is a substantial, apparently well-made motor - it sounds nice - it's quite big (the circumference of the motor body is 4.2" - a standard size it seems, but an interesting combination of decimal and imperial I thought). The instructions indicate 7 speeds of 10,000 to 22,000 rpm, but the adjustment knob has no graduated markings - the knob is just a push fit over a knurled shaft, so I will aim to replace the knob with one on which I can mark the indicated speed settings of 1-7. The only other thing I noted was that another version of the same motor I saw being sold with a spare set of carbon brushes - might try to get a set from somewhere if that is an indicator they are likely to wear out.

There are various designs of router lift and ideally you would fit this motor to a lift designed for this type of router motor (with a clamp that fits around the motor body). My old-style Rout-r-Lift is designed to fix by bolting onto the base of a plunge router, so it took some head scratching to work out how to fit the Xact motor. In case anyone is interested, I have shown some detail below of how I installed the motor.

The two challenges were fitting the motor body to my Rout-r-Lift and getting good dust extraction. I did find a write-up of someone who had made an mdf collar for the router motor for this situation; I cannot now find the source, but acknowledge that I stole the basic solution of the mdf collar.

The biggest problem I had was finding a way of routing the cut out circle for the collar – this led to me making the small-circle cutter jig for the Festool OF1010 that I have written up here http://festoolownersgroup.com/festool-t ... #msg428723

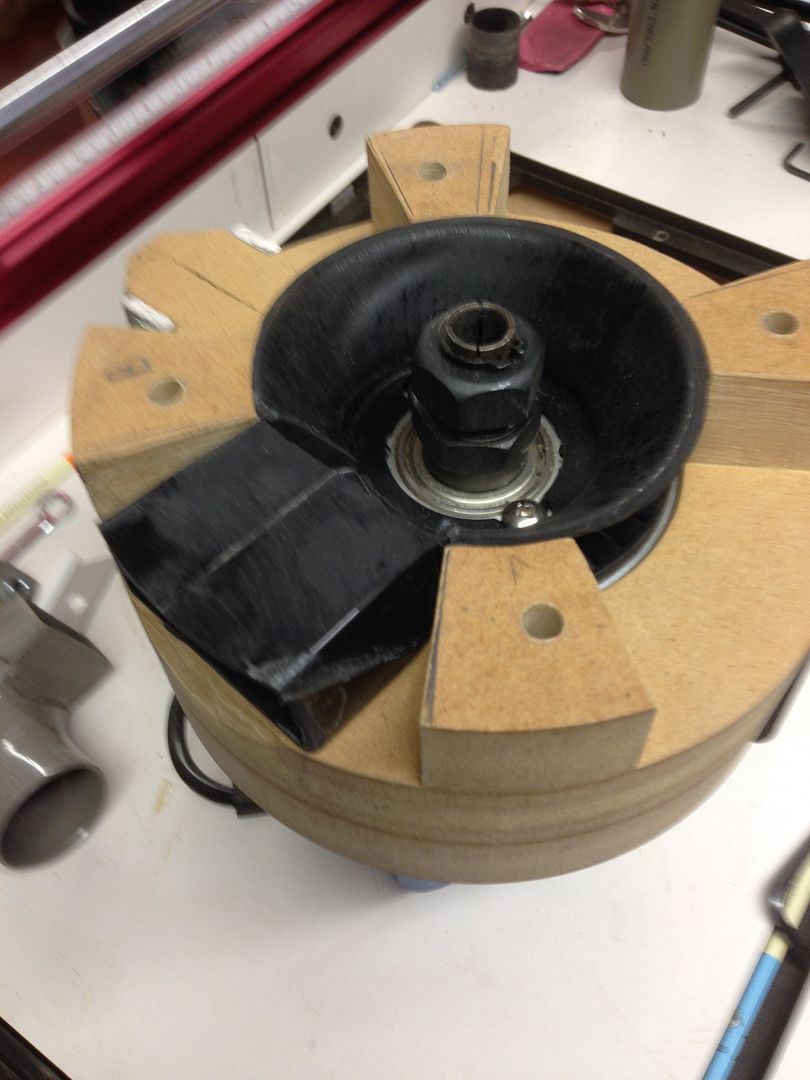

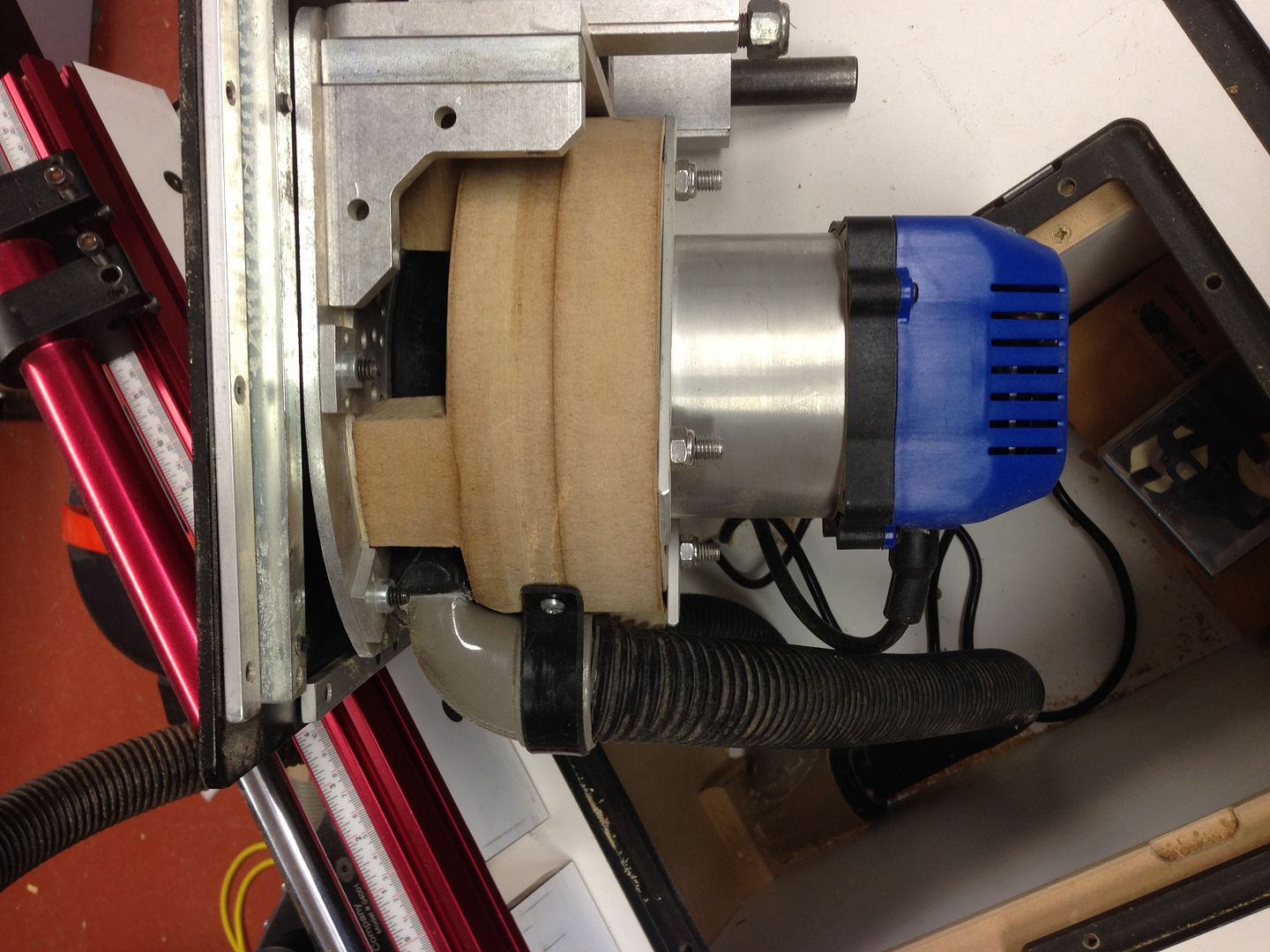

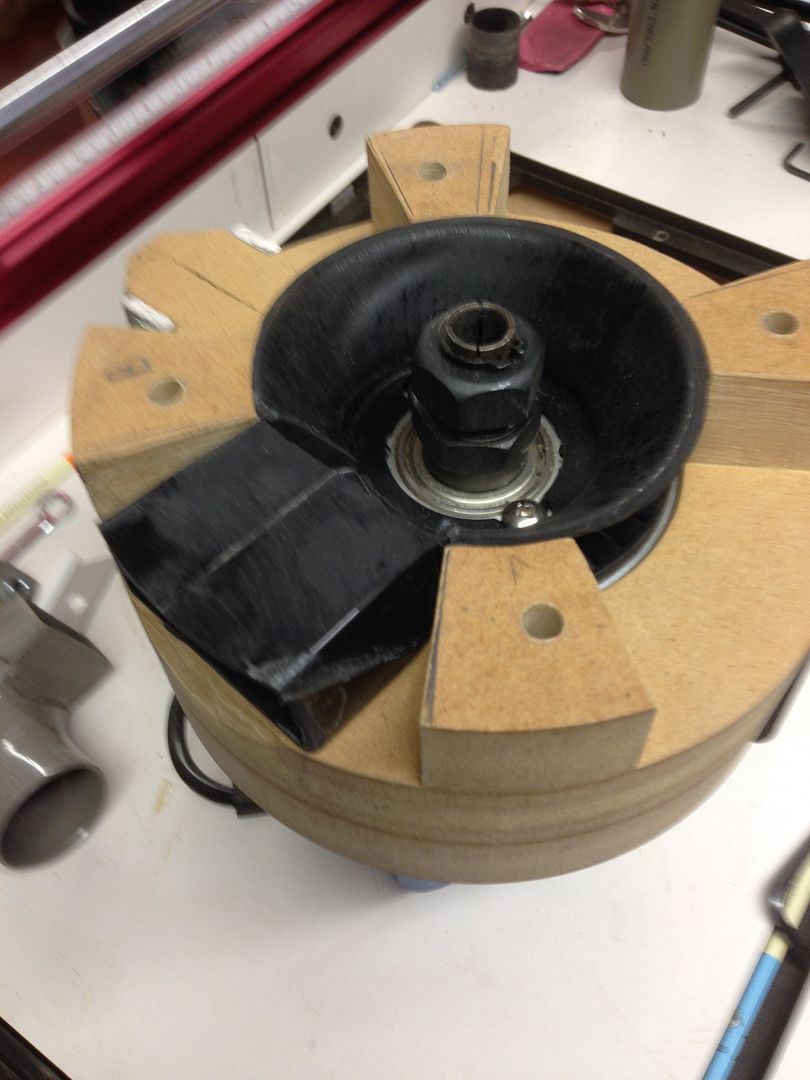

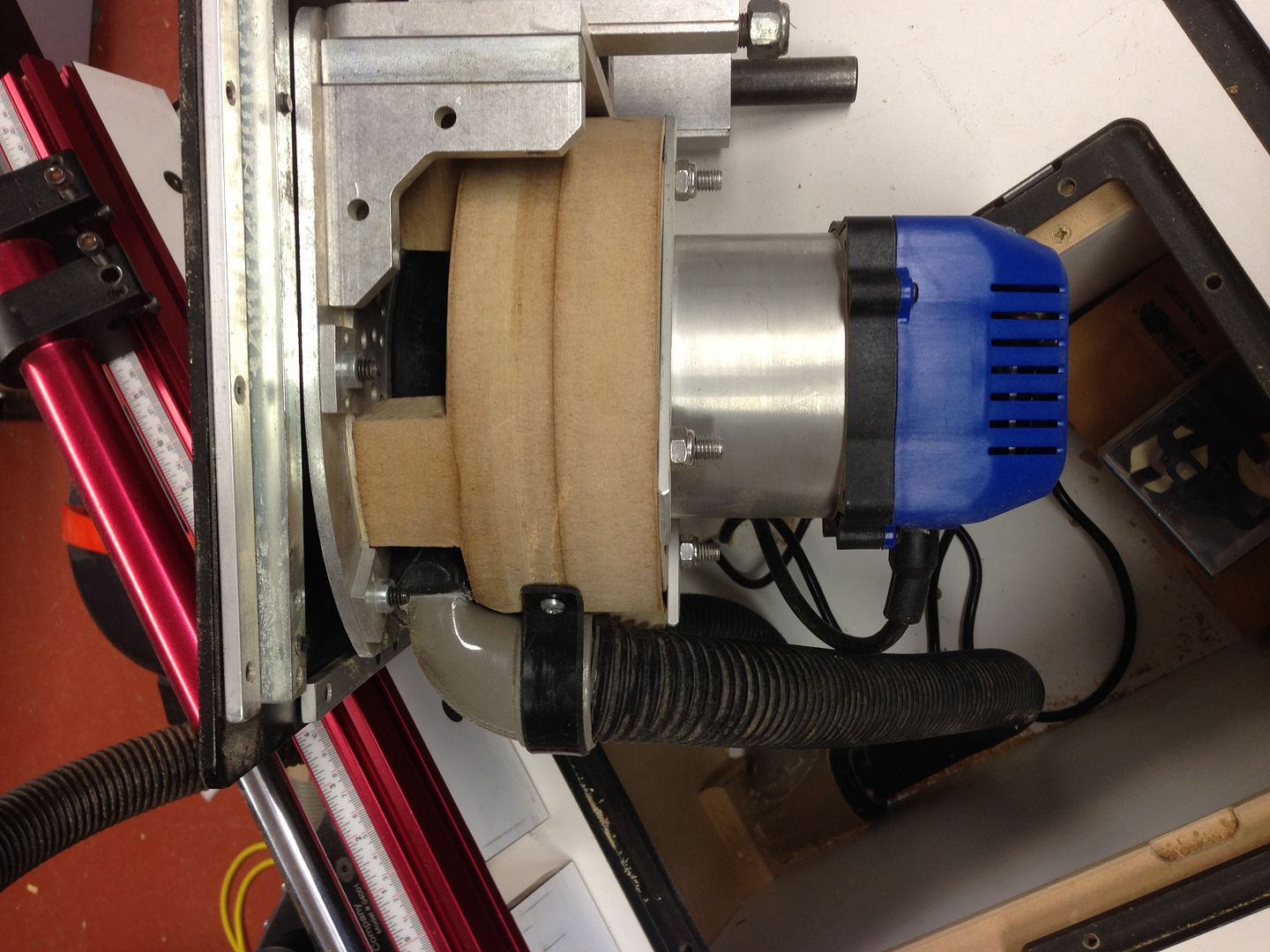

The next problem was how to provide for the cooling airflow from the motor as well as good dust extraction and access to the collet nuts etc. As the pictures show, the cooling airflow comes out of the vent at the cutter end of the motor; it is a pretty strong airflow when running at full speed. I did this by making a cone shaped deflector through which I have fashioned an extraction chute.

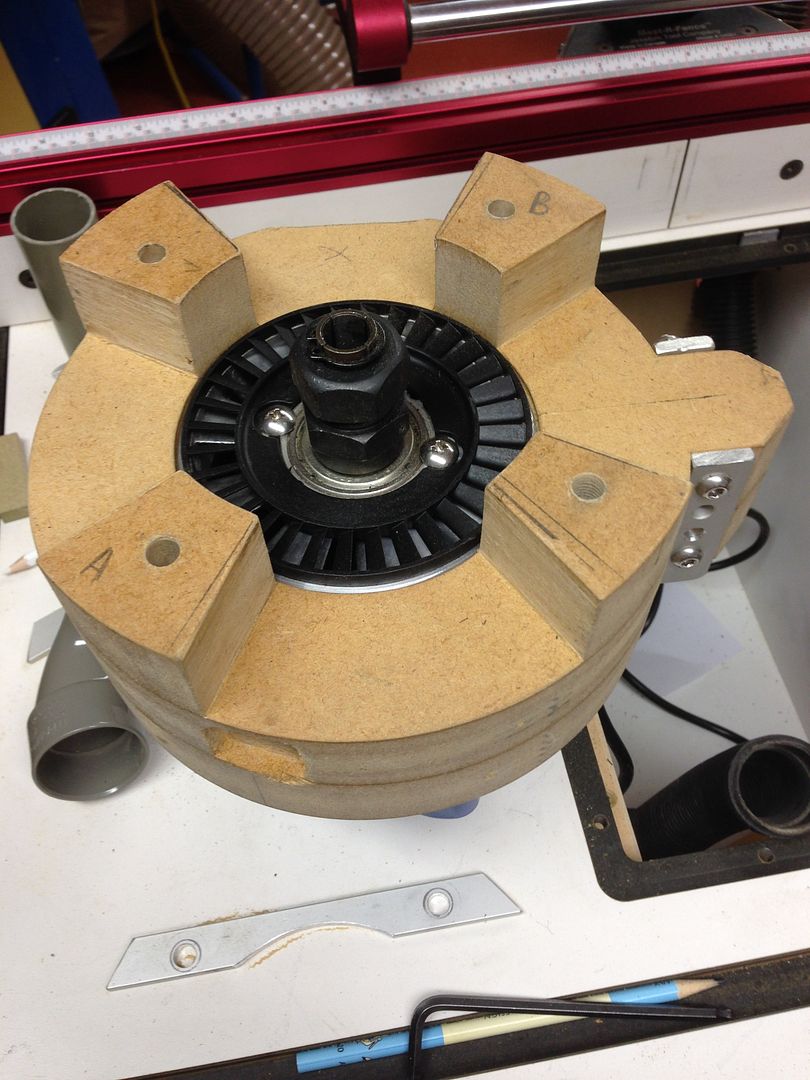

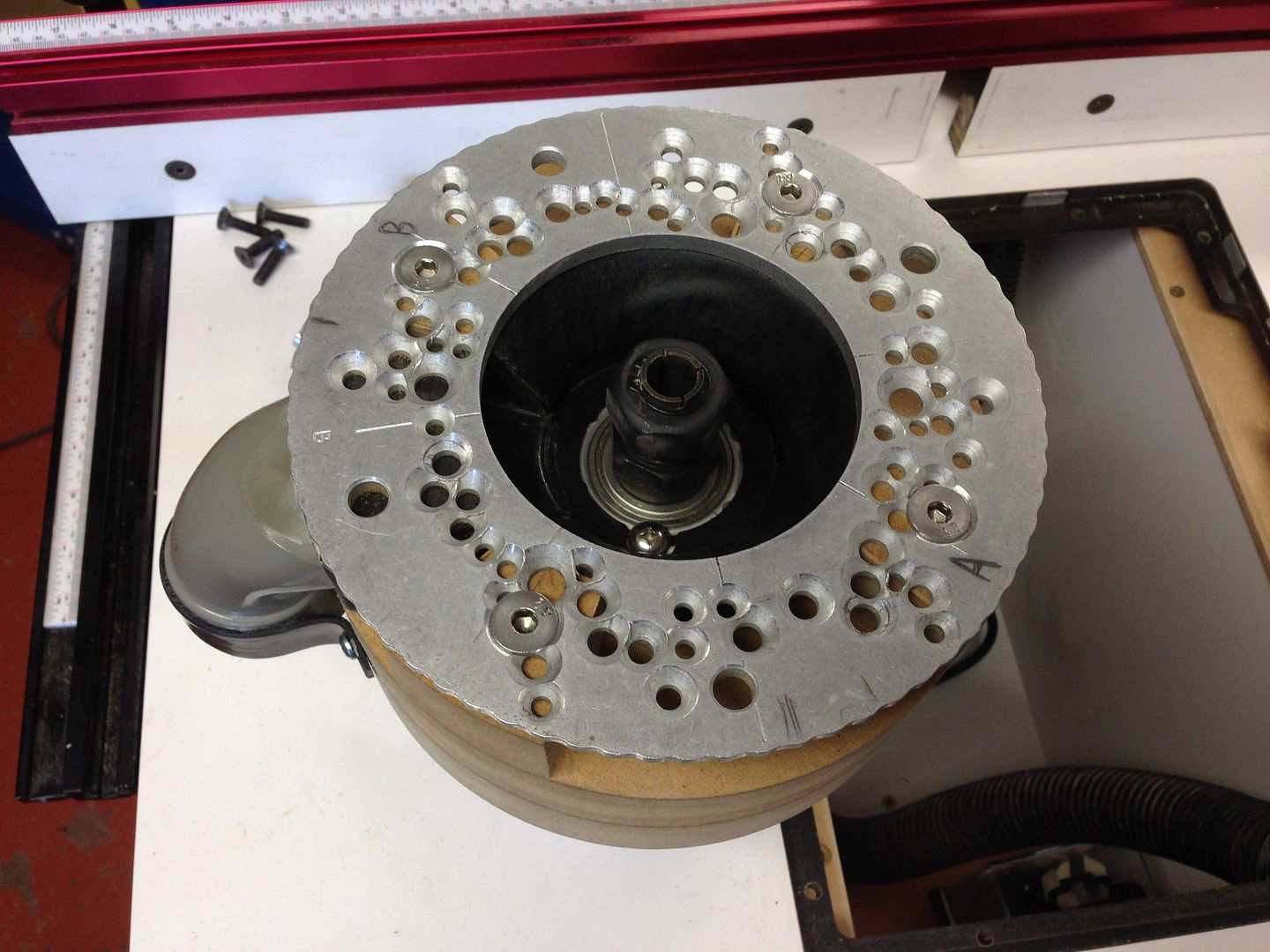

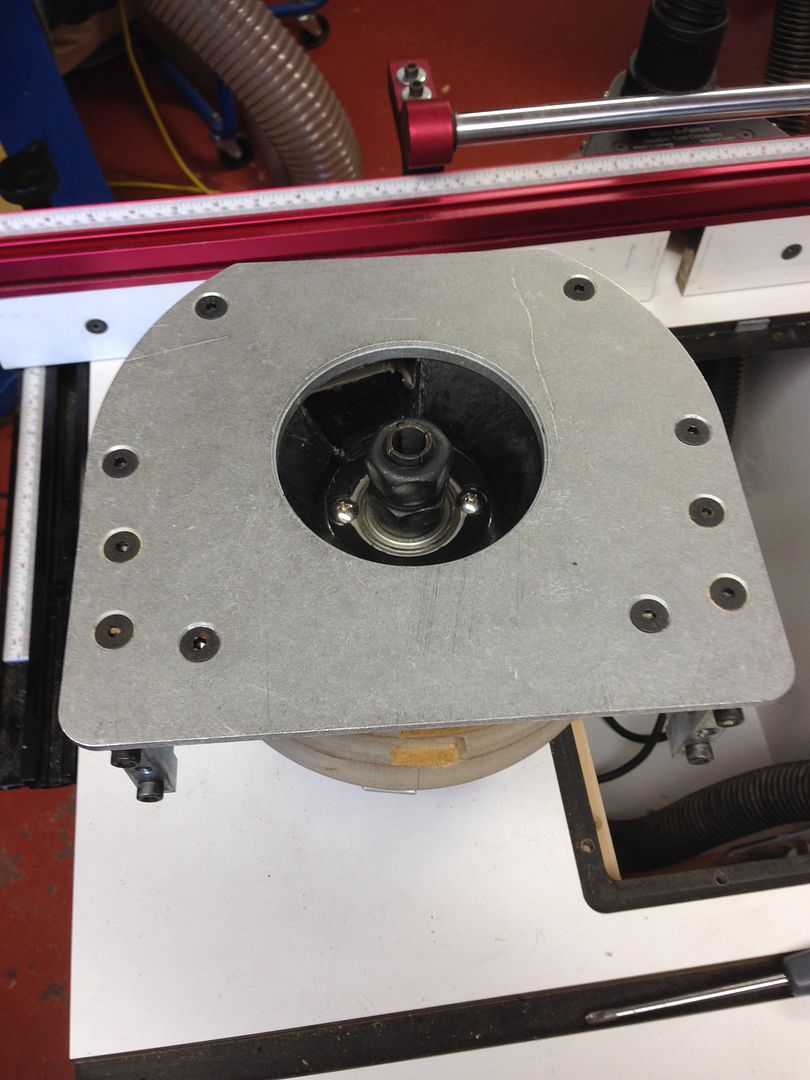

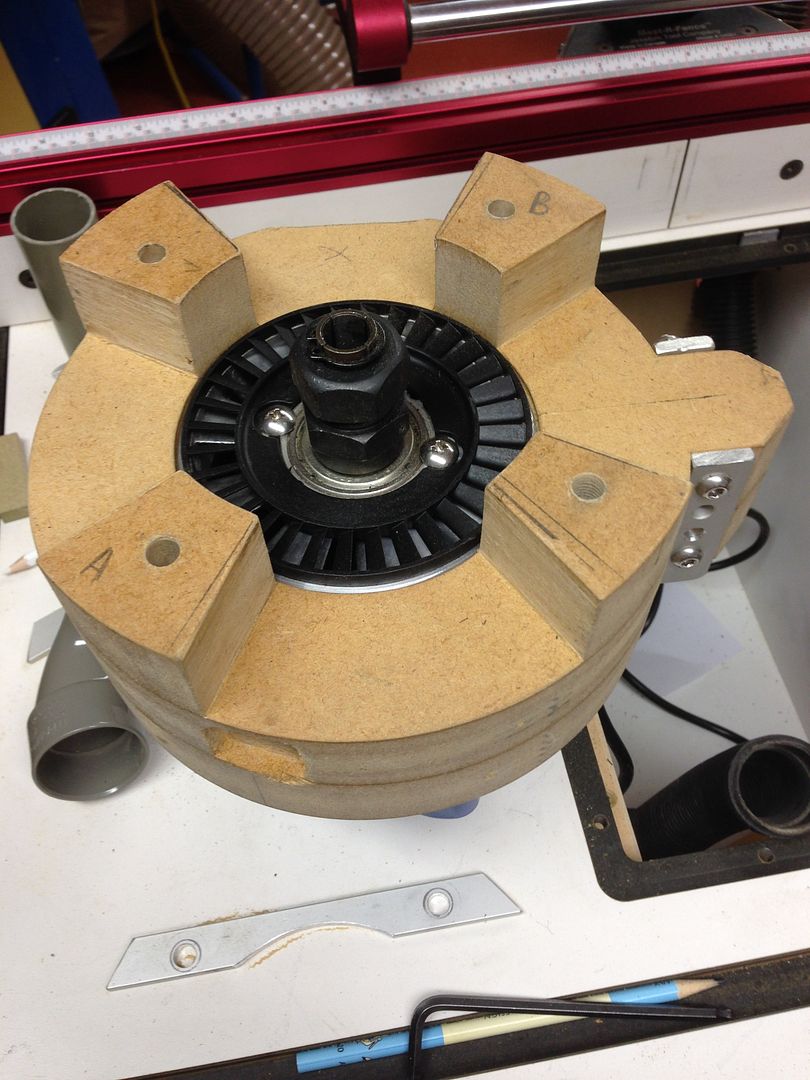

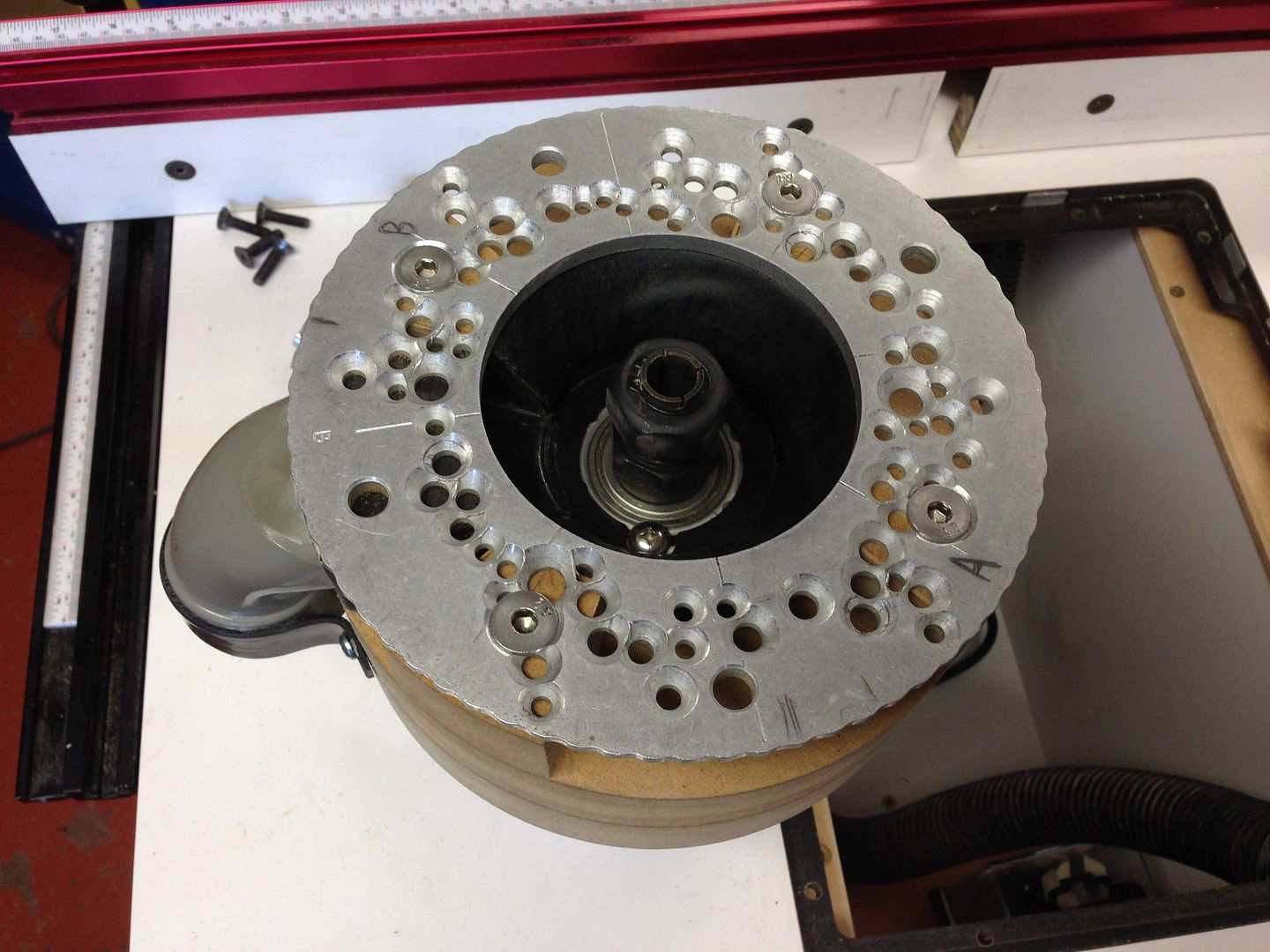

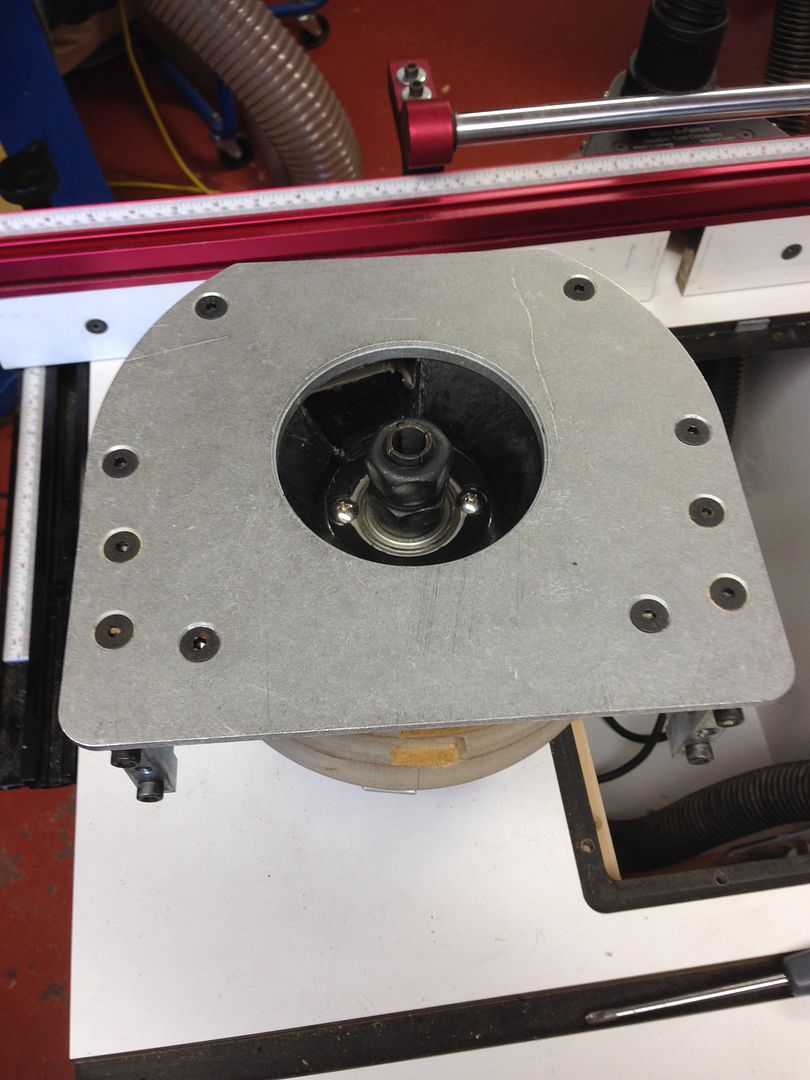

The collar was made out of three thicknesses of 30mm mdf glued together. The circles were cut out as far as possible with the OF1010 then with a bearing guided cutter using the existing router table (yes, you need one to make one…, although alternative methods exist). This was a loose fit over the motor body and then a bandsaw cut made through the projecting wings on the collar; when the wings are bolted together, this enables the collar to be clamped tight around the body.

I cut out sections on the top to allow for airflow from the motor and the extraction chute – just had to spend a few ££ on some M8 countersunk bolts to fix the Rout-r-Lift plate (screws might have been ok, but the remaining mdf was potentially weak where I had cut out and I wanted to bolt it tight – I had some strips of aluminium that very handily had a part circular cut out that just about fitted the circumference of the motor body – these I used for clamping bars.

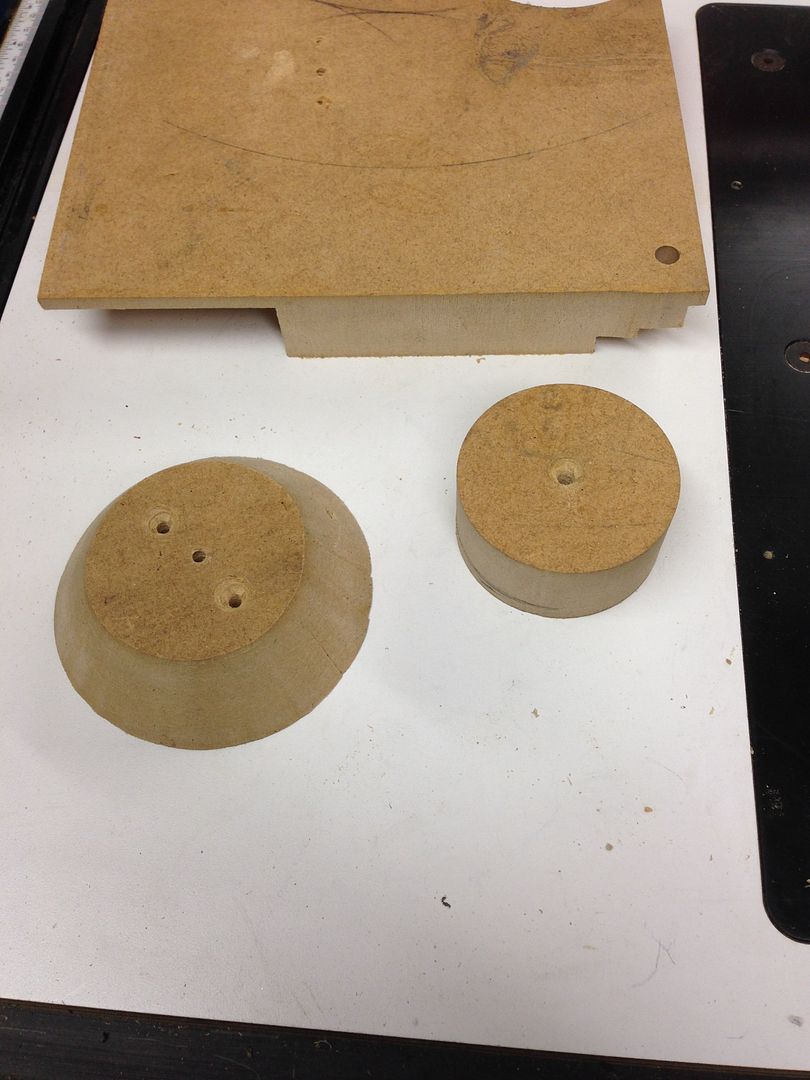

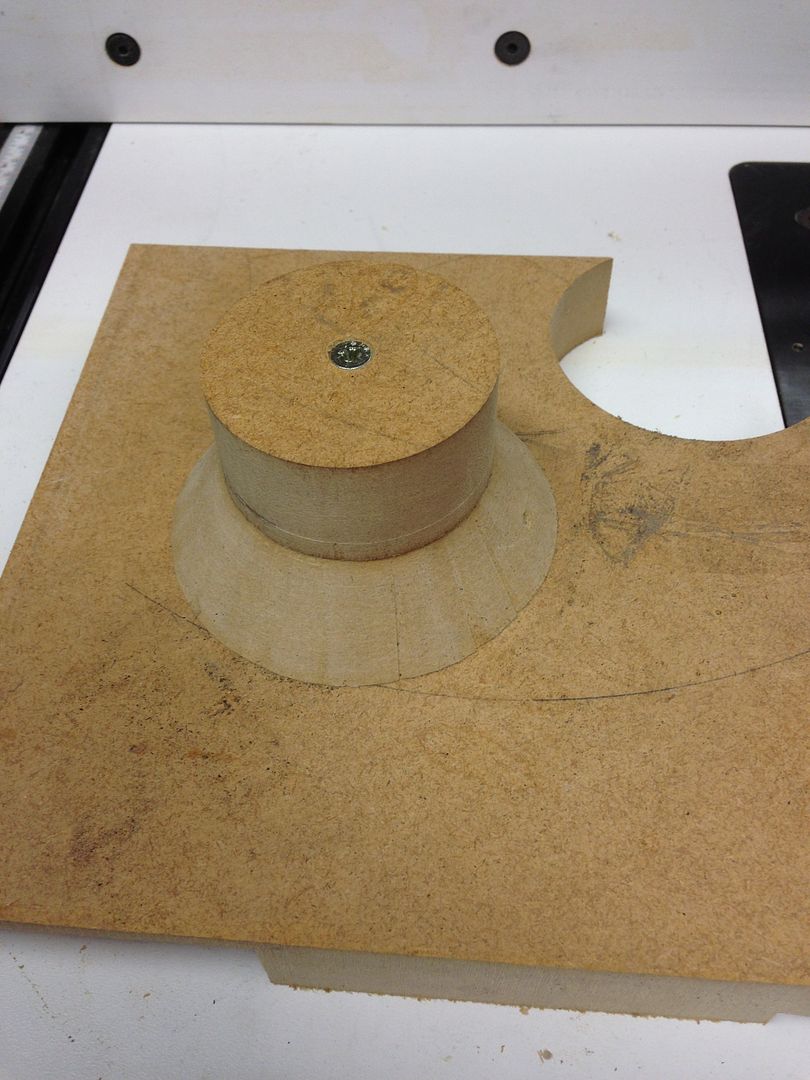

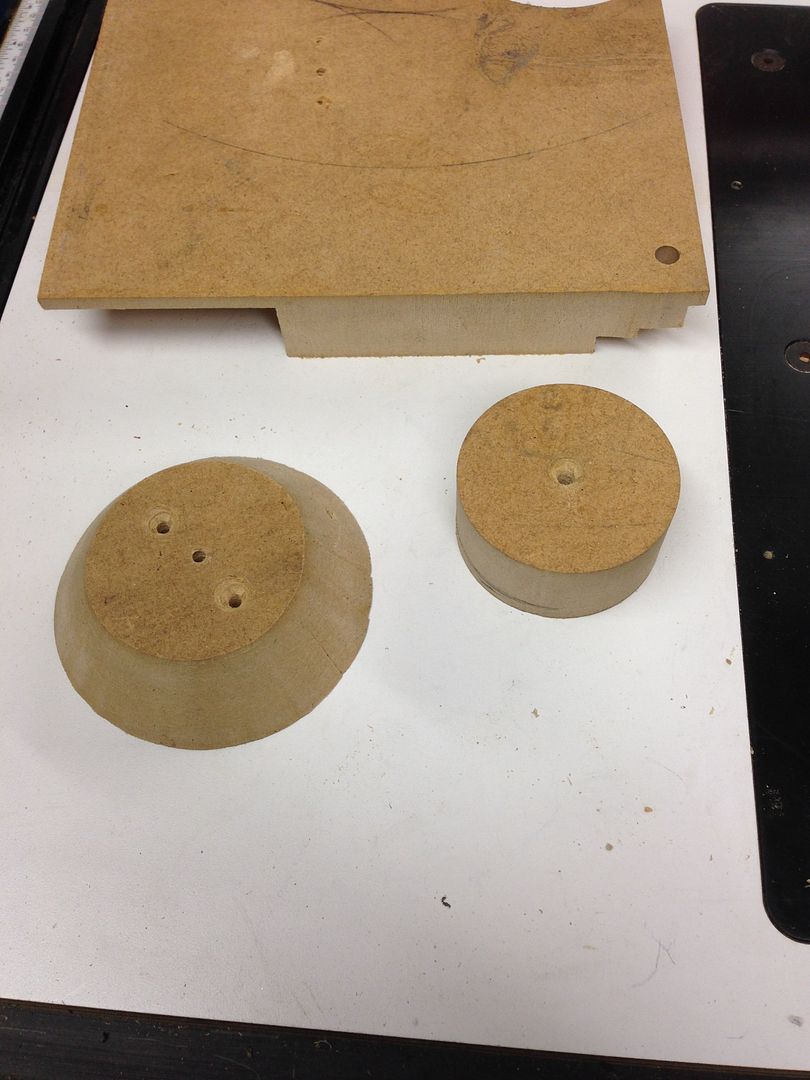

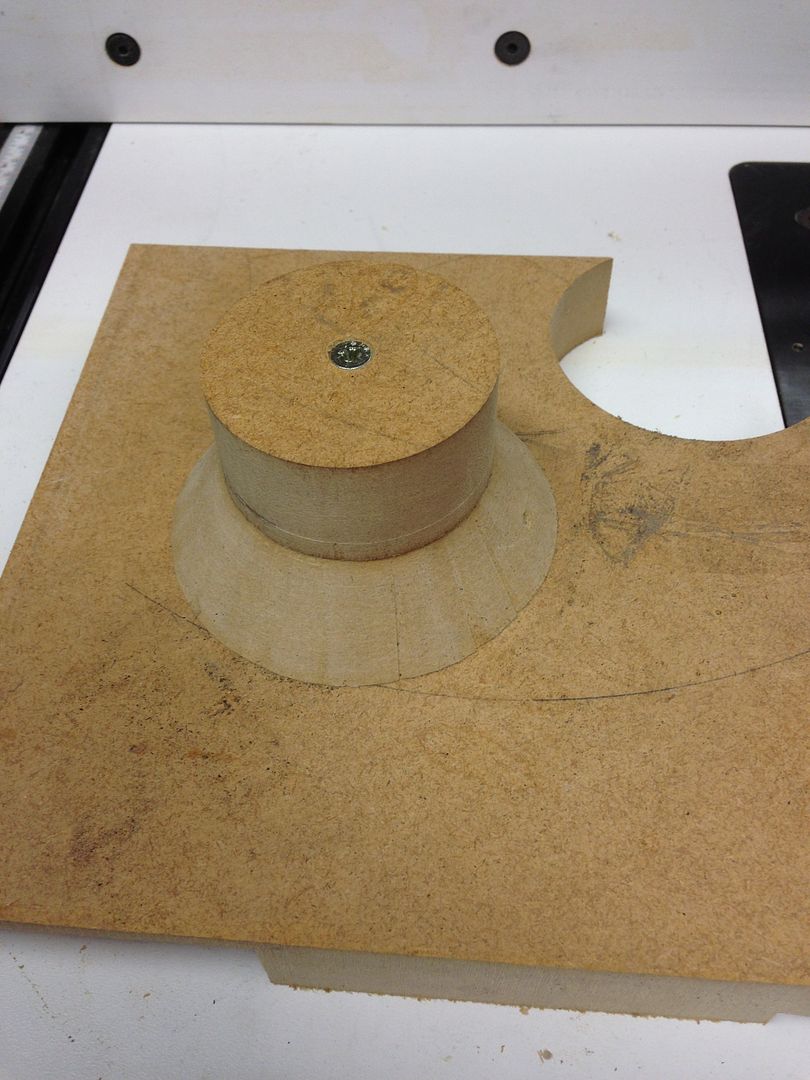

The conical deflector was made by softening some plastic rainwater downpipe over a former (made mostly with said circle cutter) and the dust extraction chute and elbow was fashioned by softening and shaping another bit of pipe and a 40mm drainage elbow – this was a bit of a faff, but once done, works very well.

Anyway, here are some pictures for those sufficiently interested.

The mdf collar fitted and clamped

The cone former:

The deflector/dust extraction chute:

The assembly:

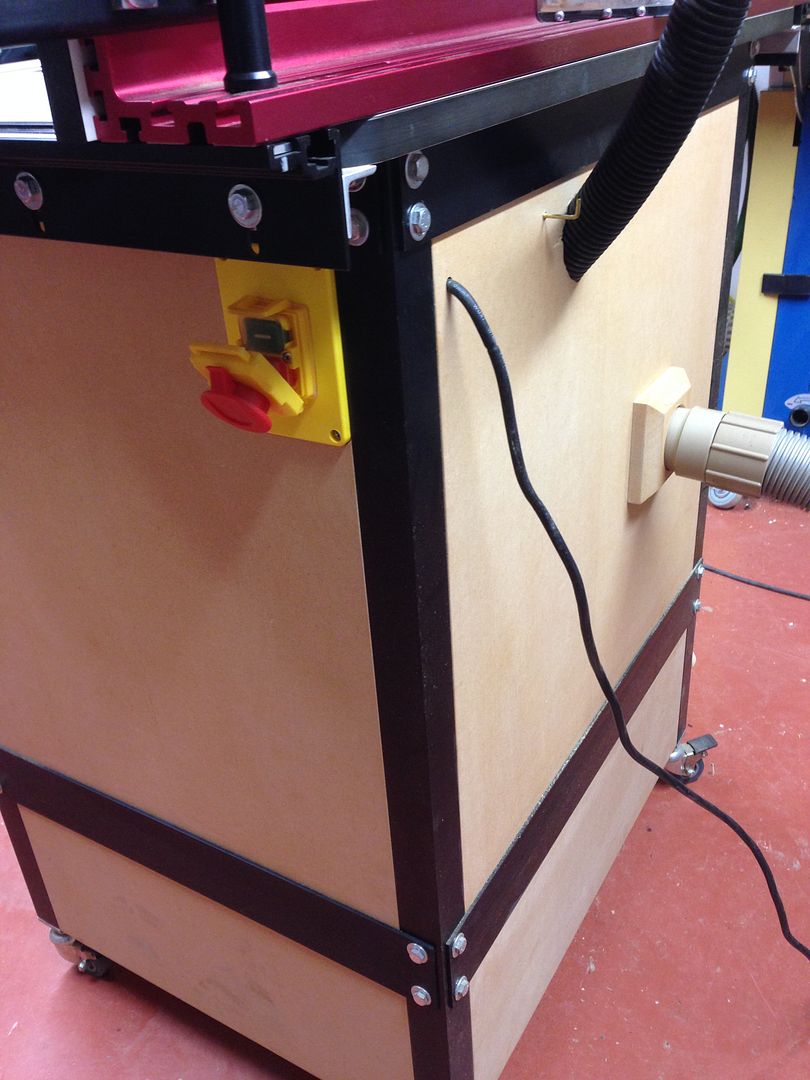

Dust extraction is one hose to the router and one to the back of the fence, joined by a fabricated Y-piece:

It all seems to work rather well and I have struggled thus far to find a combination of positions that deposits any chipping/dust in the space below the router, so the dust extraction is definitely superior to what I had before.

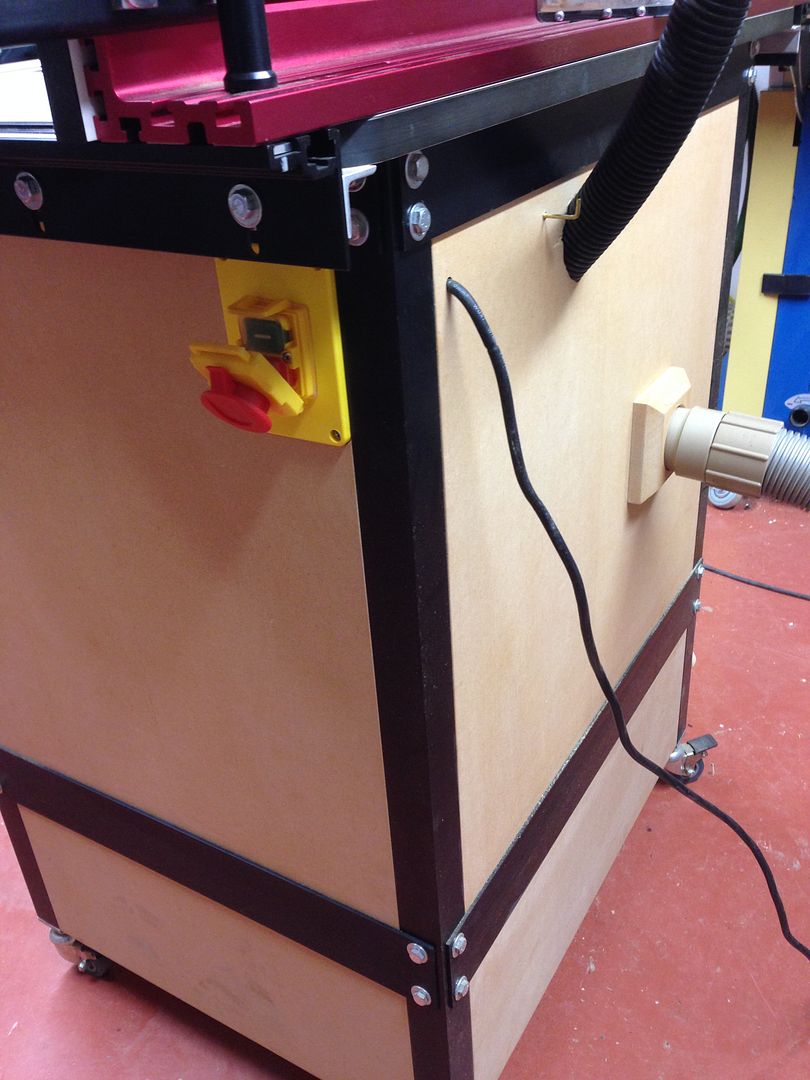

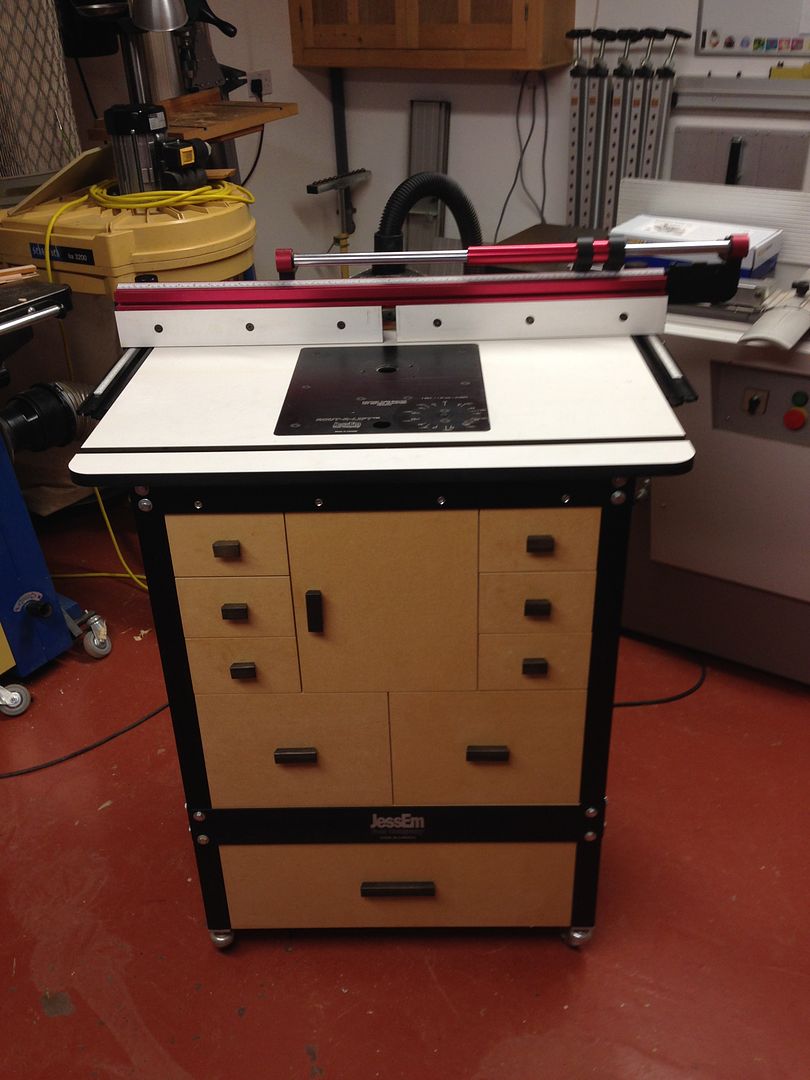

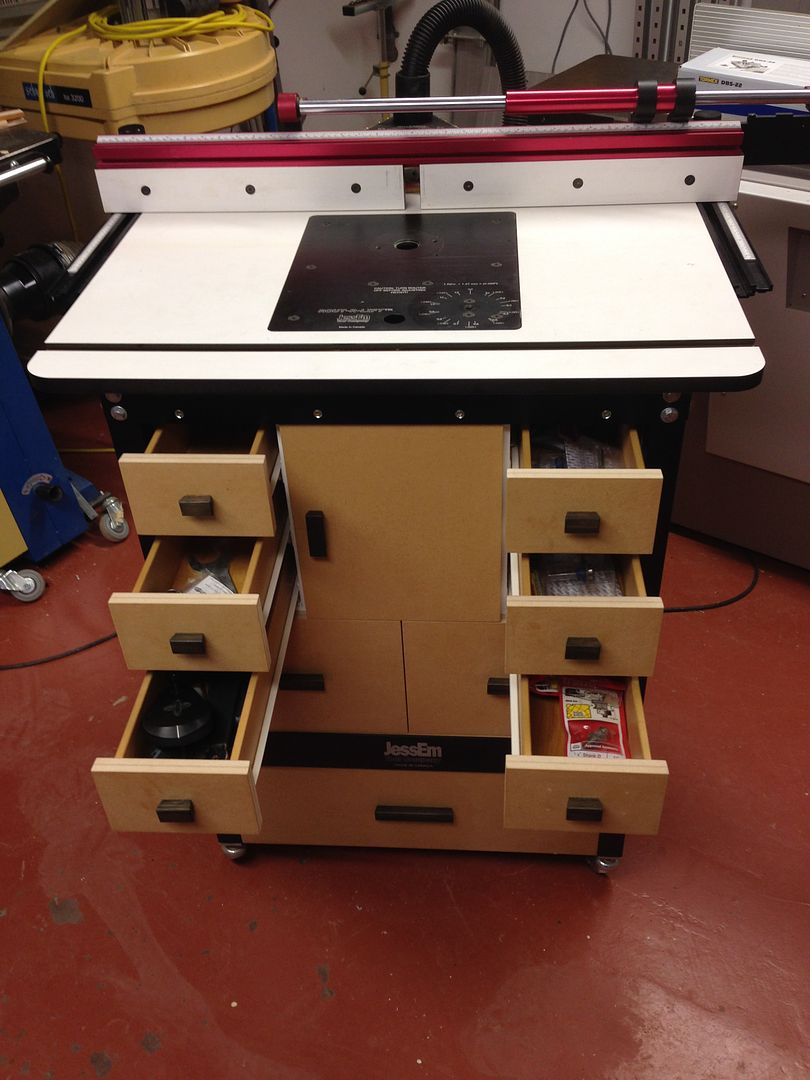

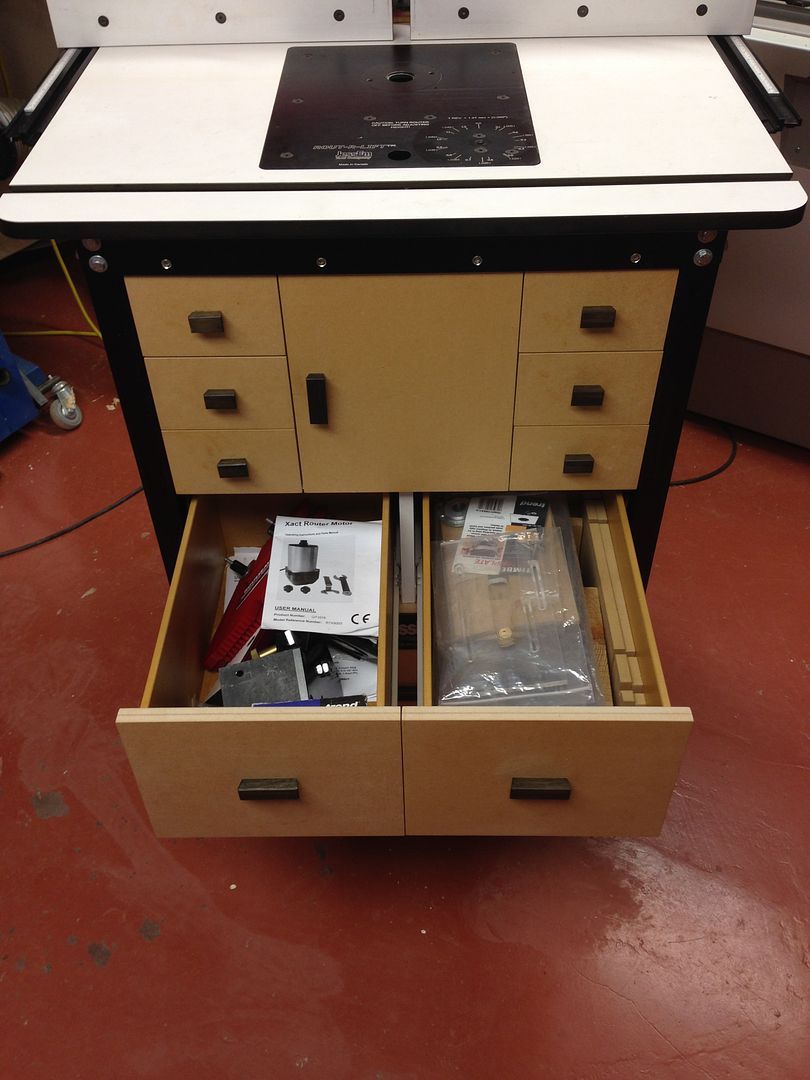

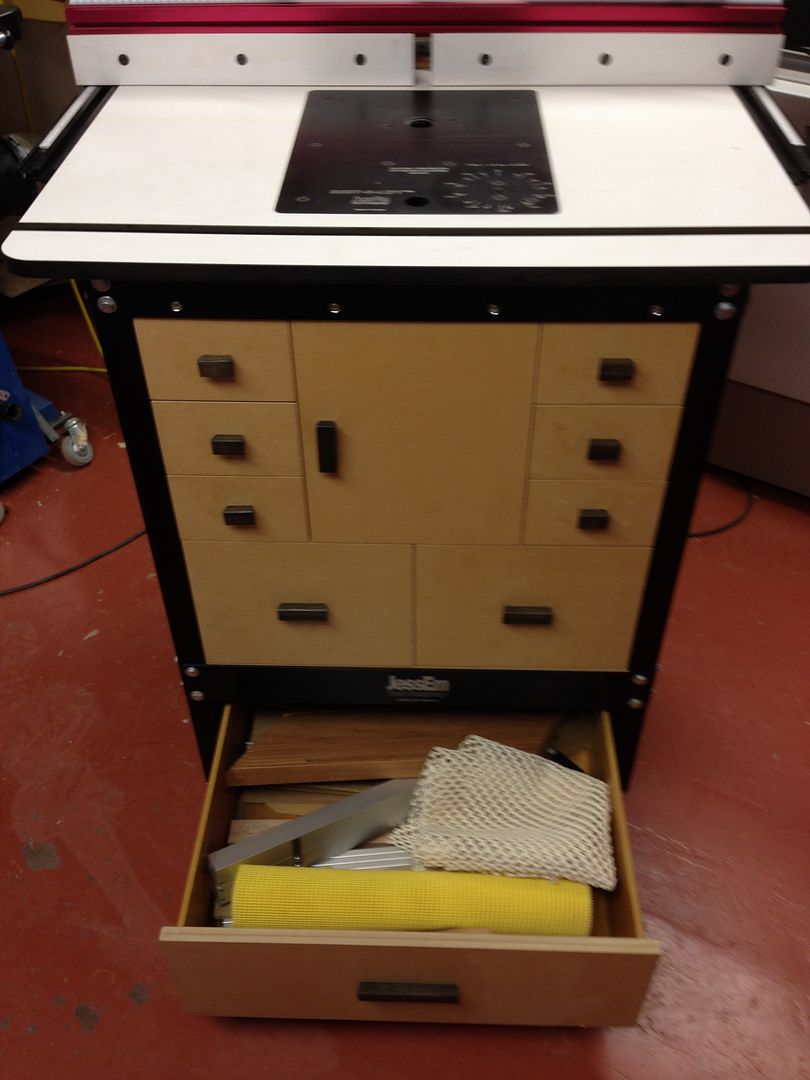

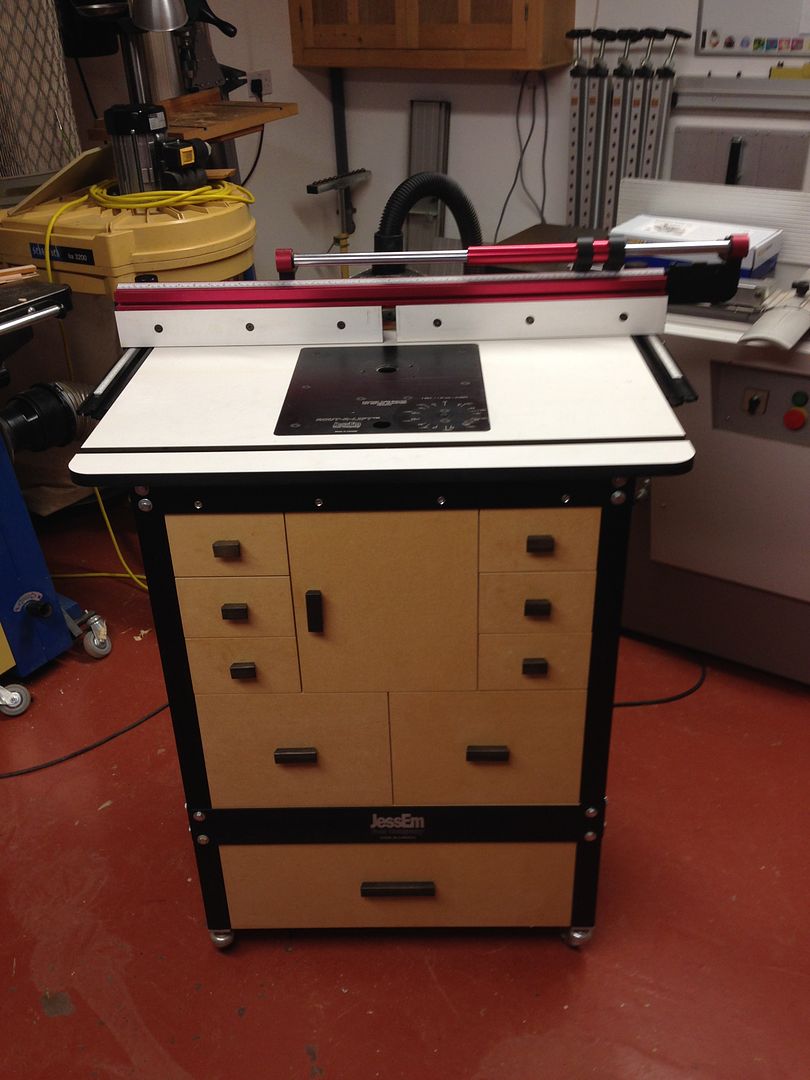

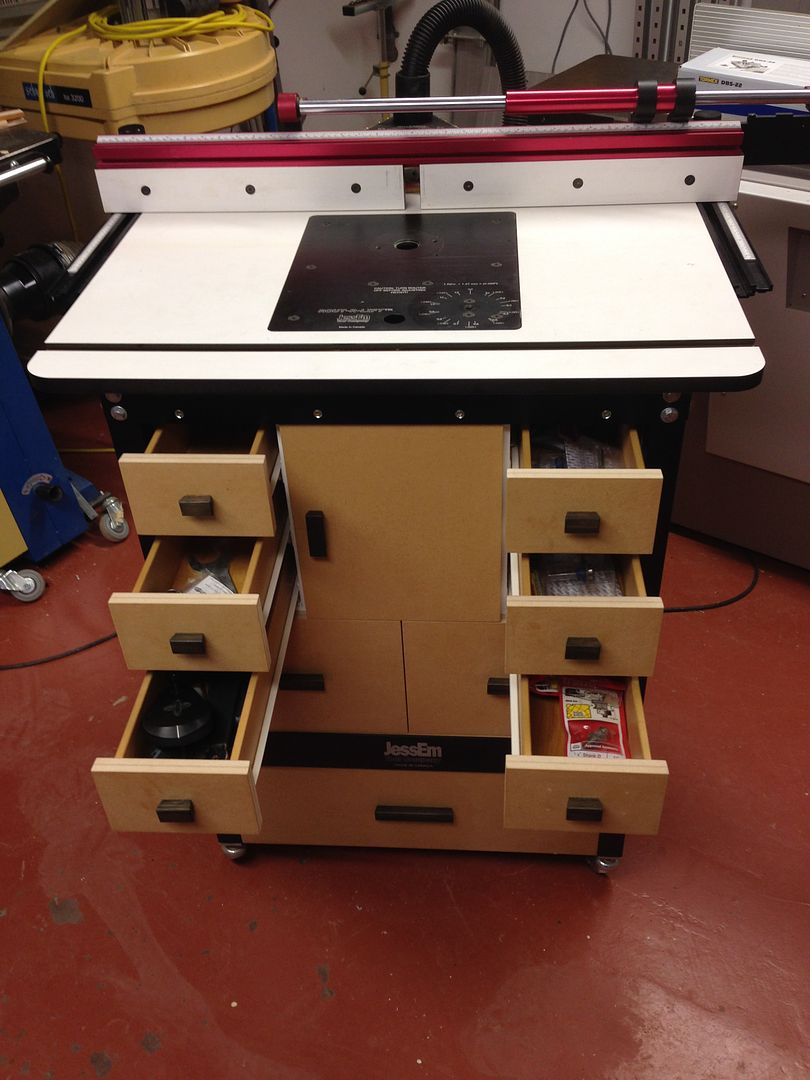

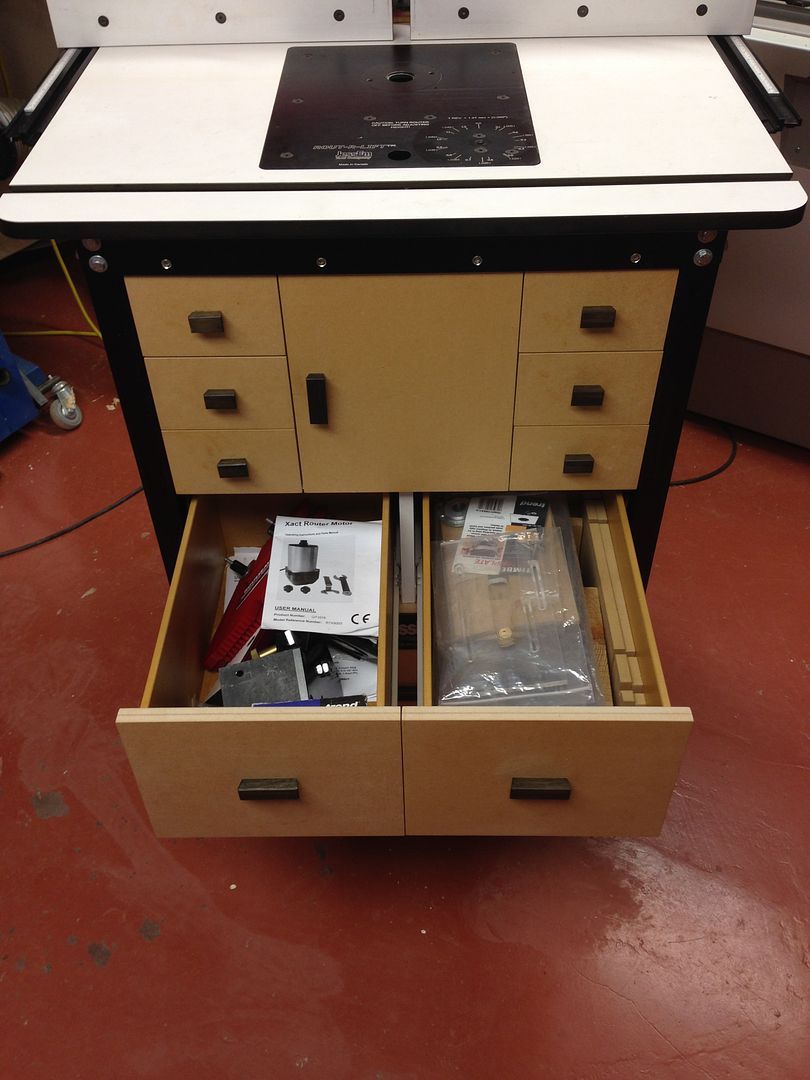

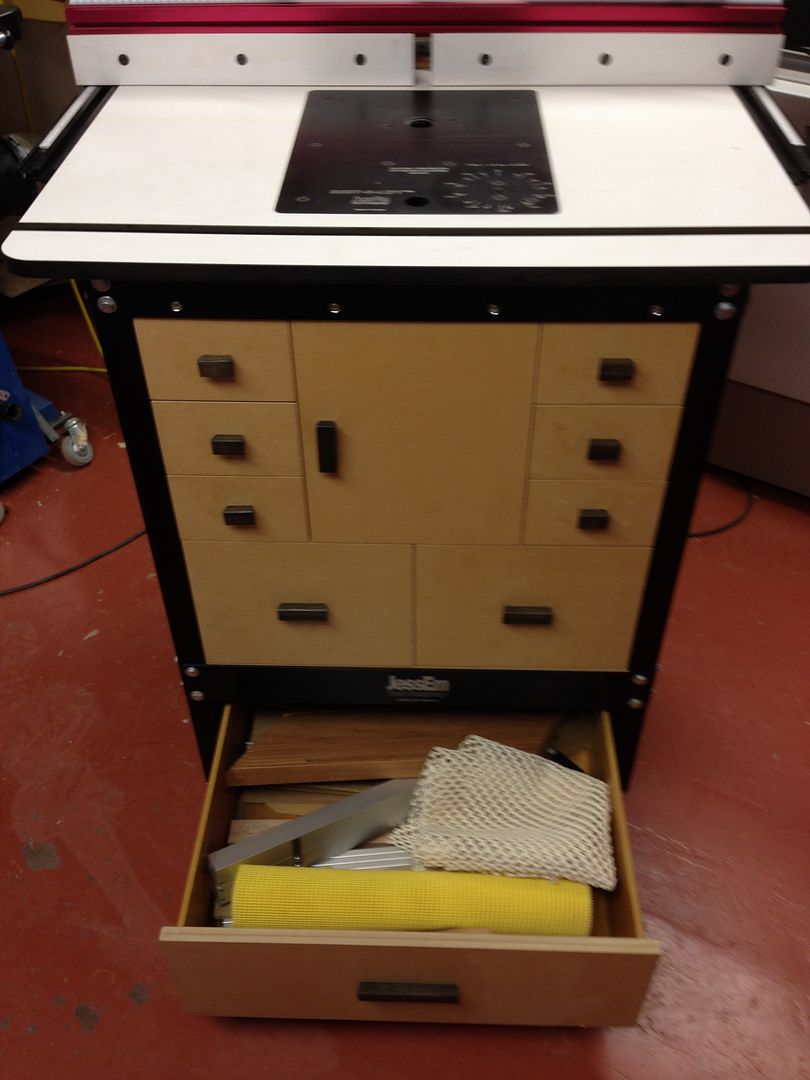

And here are a few pictures of the router table generally, in case anyone is interested – I made the unit a while ago to fit inside the aluminium frame of the router table – I did this ‘cos I had it, but it probably would have been just as good and quick (maybe quicker) to make a dedicated carcase that the phenolic top would fit on. The mdf panels were sealed with sanding sealer and one day I might get around to spray-painting them as intended. The original frame came with adjustable feet that were good quality, but I needed wheels, so added those (had to drill out and rethread the fixings in the legs as they were imperial and I could not find wheels to fit.) Anyway, I am happy with the whole set up now.

hmm, sorry if I went OTT on the pictures.

cheers

This router motor seems to be sold under many different labels and I guess they are made in vast quantities in China - doesn't seem any the worse for that. It is powerful with input/output of 2400W/1800W which compares with the T11 that is no slouch at 2000W/1400W and a slightly higher max speed of 22,000rpm v 20,000rpm. On inspection, the collets (½” and ¼”) look rather cheap compared to the T11’s – retained in the collet nut by a circlip rather than the click in design on the T11, but I intend to fit a quick release chuck that makes for much easier cutter change in the router table.

Otherwise it is a substantial, apparently well-made motor - it sounds nice - it's quite big (the circumference of the motor body is 4.2" - a standard size it seems, but an interesting combination of decimal and imperial I thought). The instructions indicate 7 speeds of 10,000 to 22,000 rpm, but the adjustment knob has no graduated markings - the knob is just a push fit over a knurled shaft, so I will aim to replace the knob with one on which I can mark the indicated speed settings of 1-7. The only other thing I noted was that another version of the same motor I saw being sold with a spare set of carbon brushes - might try to get a set from somewhere if that is an indicator they are likely to wear out.

There are various designs of router lift and ideally you would fit this motor to a lift designed for this type of router motor (with a clamp that fits around the motor body). My old-style Rout-r-Lift is designed to fix by bolting onto the base of a plunge router, so it took some head scratching to work out how to fit the Xact motor. In case anyone is interested, I have shown some detail below of how I installed the motor.

The two challenges were fitting the motor body to my Rout-r-Lift and getting good dust extraction. I did find a write-up of someone who had made an mdf collar for the router motor for this situation; I cannot now find the source, but acknowledge that I stole the basic solution of the mdf collar.

The biggest problem I had was finding a way of routing the cut out circle for the collar – this led to me making the small-circle cutter jig for the Festool OF1010 that I have written up here http://festoolownersgroup.com/festool-t ... #msg428723

The next problem was how to provide for the cooling airflow from the motor as well as good dust extraction and access to the collet nuts etc. As the pictures show, the cooling airflow comes out of the vent at the cutter end of the motor; it is a pretty strong airflow when running at full speed. I did this by making a cone shaped deflector through which I have fashioned an extraction chute.

The collar was made out of three thicknesses of 30mm mdf glued together. The circles were cut out as far as possible with the OF1010 then with a bearing guided cutter using the existing router table (yes, you need one to make one…, although alternative methods exist). This was a loose fit over the motor body and then a bandsaw cut made through the projecting wings on the collar; when the wings are bolted together, this enables the collar to be clamped tight around the body.

I cut out sections on the top to allow for airflow from the motor and the extraction chute – just had to spend a few ££ on some M8 countersunk bolts to fix the Rout-r-Lift plate (screws might have been ok, but the remaining mdf was potentially weak where I had cut out and I wanted to bolt it tight – I had some strips of aluminium that very handily had a part circular cut out that just about fitted the circumference of the motor body – these I used for clamping bars.

The conical deflector was made by softening some plastic rainwater downpipe over a former (made mostly with said circle cutter) and the dust extraction chute and elbow was fashioned by softening and shaping another bit of pipe and a 40mm drainage elbow – this was a bit of a faff, but once done, works very well.

Anyway, here are some pictures for those sufficiently interested.

The mdf collar fitted and clamped

The cone former:

The deflector/dust extraction chute:

The assembly:

Dust extraction is one hose to the router and one to the back of the fence, joined by a fabricated Y-piece:

It all seems to work rather well and I have struggled thus far to find a combination of positions that deposits any chipping/dust in the space below the router, so the dust extraction is definitely superior to what I had before.

And here are a few pictures of the router table generally, in case anyone is interested – I made the unit a while ago to fit inside the aluminium frame of the router table – I did this ‘cos I had it, but it probably would have been just as good and quick (maybe quicker) to make a dedicated carcase that the phenolic top would fit on. The mdf panels were sealed with sanding sealer and one day I might get around to spray-painting them as intended. The original frame came with adjustable feet that were good quality, but I needed wheels, so added those (had to drill out and rethread the fixings in the legs as they were imperial and I could not find wheels to fit.) Anyway, I am happy with the whole set up now.

hmm, sorry if I went OTT on the pictures.

cheers