Derek Cohen (Perth Oz)

Established Member

I purchased this scratch stock several months ago following discussion on this forum. BB resurrected the thread, and I thought it more appropriate to begin a fresh thread with a short review.

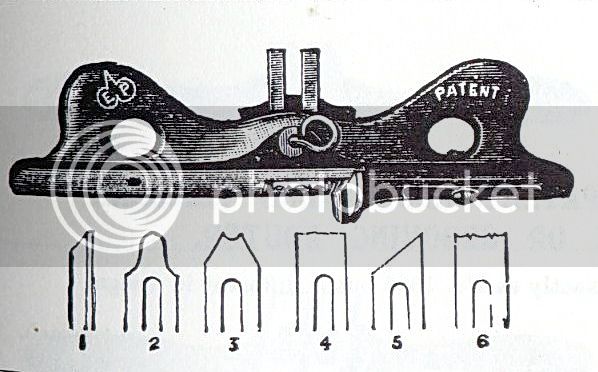

The scratch stock is a remake of the Preston's Patent Reeding, Rabbeting and Moulding (Tool No.1393S). Here are photos of the original Preston ...

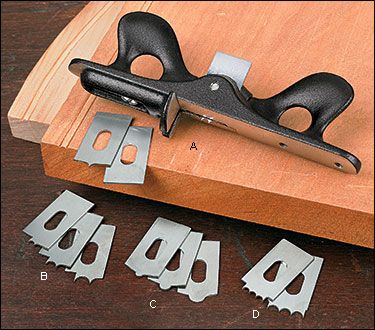

The Lee Valley version ...

There are a two changes, apart from the cutters. These are the screw for an eye bolt - I think I would prefer something along the lines of this - anything to reduce using a screwdriver, and the fence. The original has a straight face - although I have seen a photo where the Preston is supplied with two fences, the other being a curved face. The Lee Valley is only supplied with a round face ...

When I purchased this scratch stock, it was to create beads for drawer slips ...

The first ones were built with a Lie Nielsen #66 ...

Here is a break down of the Lee Valley (Preston) alongside the #66 for comparison. The LV is significantly smaller. One of the reasons I was interested in purchasing it was for use on curves or small sections.

The LV cutters are shorter and thinner than those supplied by LN. I like the LN for their solid construction. The LV cutters will flex more. What I like especially about the LV cutters is that their arris is so much finer, and this is able to cut a finer, sharper profile. The downside of this finer arris is that inattention when scraping can cause the sharp edge of the arris to slice into the formed bead.

Here is the cutter in the #66 ...

In scraping a bead, the first step is to define the inside edge with a cutting gauge.

The next step is to remove some of the waste at the outside with a fine chamfer ..

The resulting bead is nicely formed ...

The nicest feature of this scratch stock is that it is easy to set up the depth of cut and the fence distance. The fence may be swapped to either side, which is important when the grain direction changes.

On the other hand, this is not an easy scratch stock to use. It is definitely not a first timer beader's choice. The reason for this is that the curved fence offers very little registration, and care must be taken to hold the body square to the side of the work piece. The face of the fence is short, and I wonder whether there is much advantage in curving it, and whether a flat face would not be a better alternative. I plan to experiment with mine - either obtain another and grind it flat, or make one from scratch.

Given the choice of this LV, which is inexpensive at $36 (USD), or a more expensive used Stanley or Record #66 on eBay, which may sell for double this, I would advise that one saves the extra pennies for the #66, especially if you are starting out. The #66 is just a more solid, easier to use performer. My opinion is very much biased by the curved fence, however, and this may change once I have experimented with it.

Regards from Perth

Derek