SkinnyB

Established Member

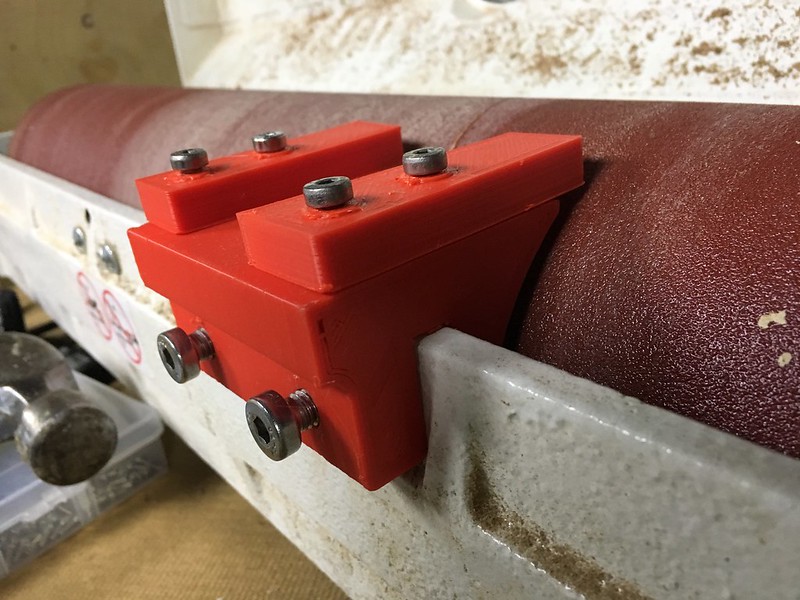

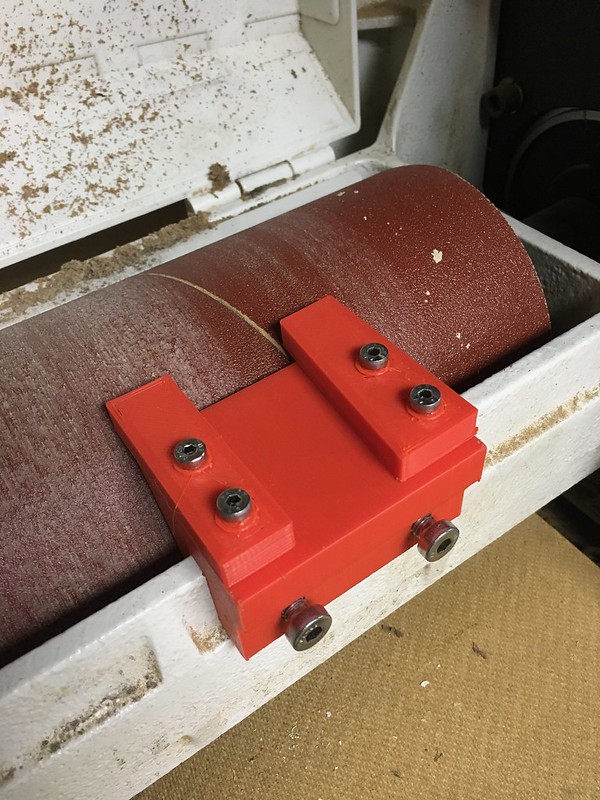

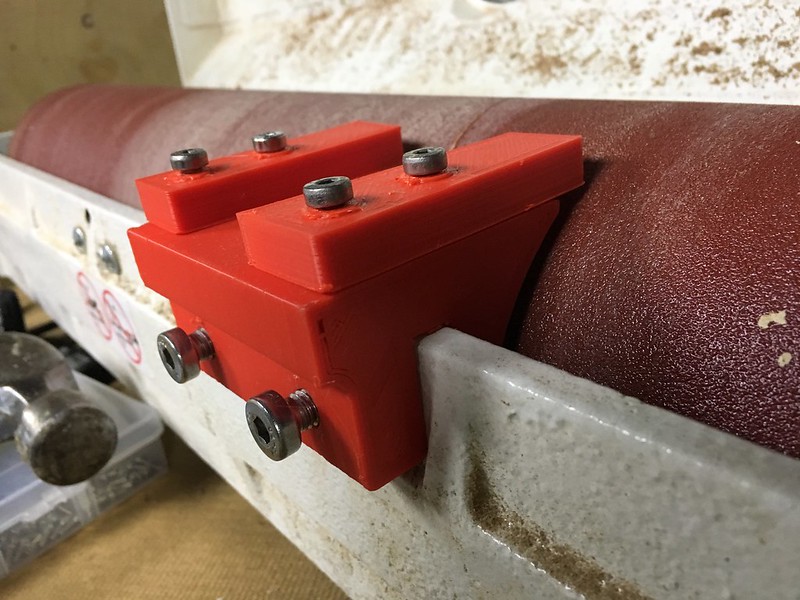

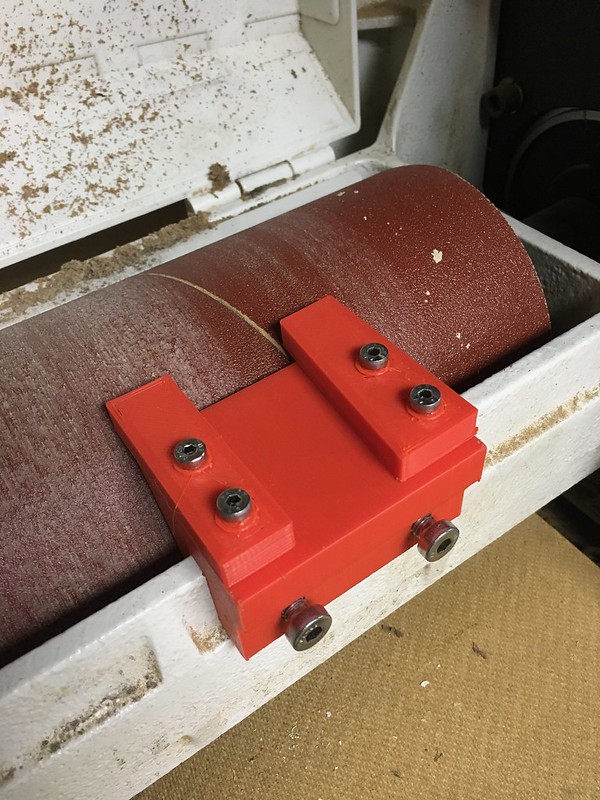

So I wanted to get a bit more from both my 3d-printer and drum sander and just wanted to design and print something useful.

I do not have a decent grinder or the space to have one at hand... And to be honest I hate sharpening so If I can utilise one of my existing tools that would be great.

So I designed this prototype jig that creates a hollow grind. Then what I want to do is add a micro bevel. Im thinking on my next revision having a removable wedge that will able to create the micro bevel. Or just a whole new separate jig.

On testing it seemed to work great. The drum is moving away from me which is the opposite to a conventional grinder. This opposite rotational motion try's to lift the chisel if I don't hold it down firmly. I thinking on the next revision i have a hold down of sorts just to stop it from lifting but still allows me to slide the chisel back and fourth.

I tested with 120 grit. My chisels are in bad shape so ill start with something more aggressive and work my up that way.

I have 240 grit that I can go down up to. I have thought about seeing if I can get finer or even a leather strop I think its called.

If I can get them reasonably sharp and then just a quick clean up on a stone ill be happy.

The left side is for straight 90 degree chisels then the right is for my Japanese chisels which I think were 98 degrees.

Just a bit of fun really. My next plan now that I have just chipped my planer blades badly. Is to create a jig for sharpening those. Like the ones where the blades are held at 45 in a piece of wood. I hoping I can do something similar then pass them under the drum sander to sharpen them. We shall see....

I do not have a decent grinder or the space to have one at hand... And to be honest I hate sharpening so If I can utilise one of my existing tools that would be great.

So I designed this prototype jig that creates a hollow grind. Then what I want to do is add a micro bevel. Im thinking on my next revision having a removable wedge that will able to create the micro bevel. Or just a whole new separate jig.

On testing it seemed to work great. The drum is moving away from me which is the opposite to a conventional grinder. This opposite rotational motion try's to lift the chisel if I don't hold it down firmly. I thinking on the next revision i have a hold down of sorts just to stop it from lifting but still allows me to slide the chisel back and fourth.

I tested with 120 grit. My chisels are in bad shape so ill start with something more aggressive and work my up that way.

I have 240 grit that I can go down up to. I have thought about seeing if I can get finer or even a leather strop I think its called.

If I can get them reasonably sharp and then just a quick clean up on a stone ill be happy.

The left side is for straight 90 degree chisels then the right is for my Japanese chisels which I think were 98 degrees.

Just a bit of fun really. My next plan now that I have just chipped my planer blades badly. Is to create a jig for sharpening those. Like the ones where the blades are held at 45 in a piece of wood. I hoping I can do something similar then pass them under the drum sander to sharpen them. We shall see....