Racers

Established Member

- Joined

- 22 Apr 2005

- Messages

- 9,172

- Reaction score

- 136

Hi,

I have loads of jobs to do, so I did something compleatly different :wink:

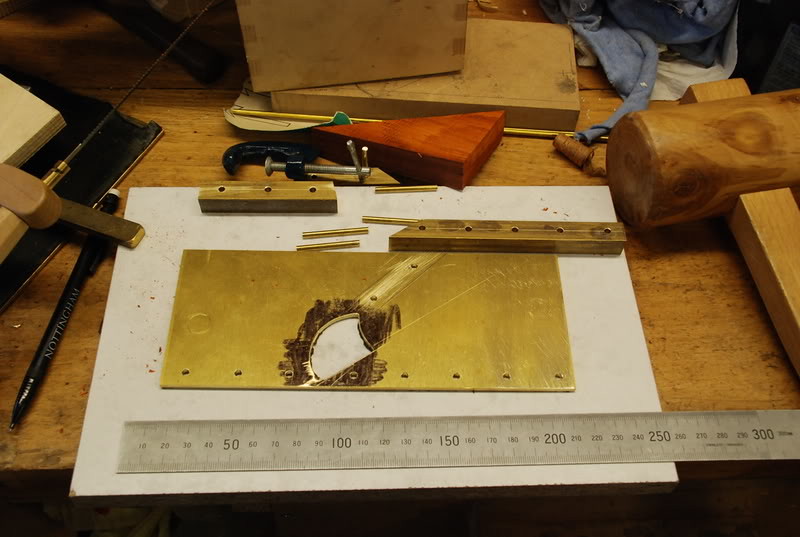

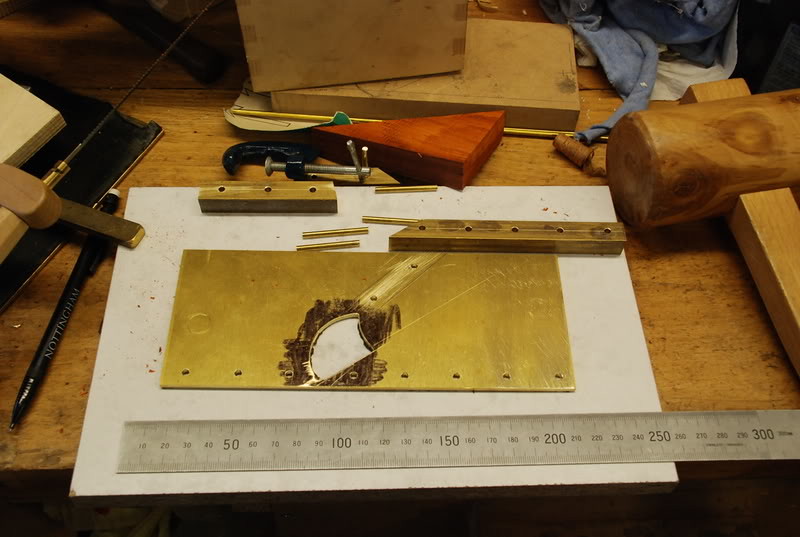

I cut up some 3mm and 1/2 inch square brass on my band saw with a fine blade.

DSC_0047 by pete maddex, on Flickr

DSC_0047 by pete maddex, on Flickr

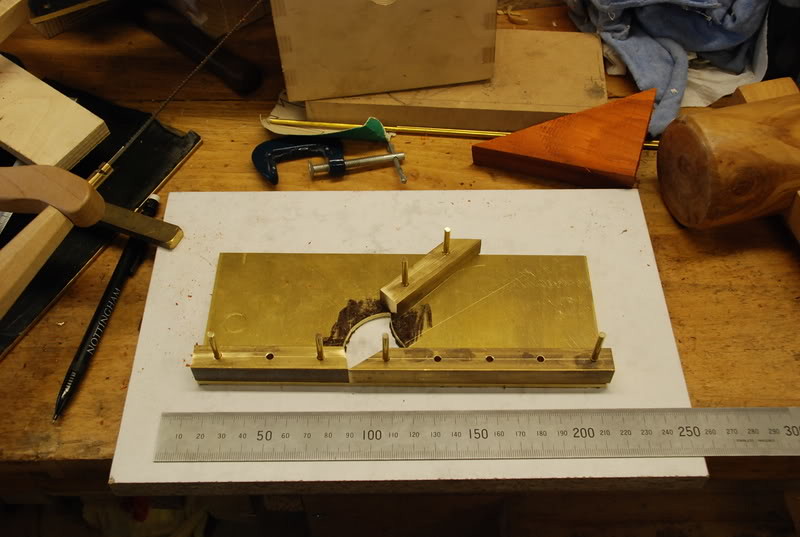

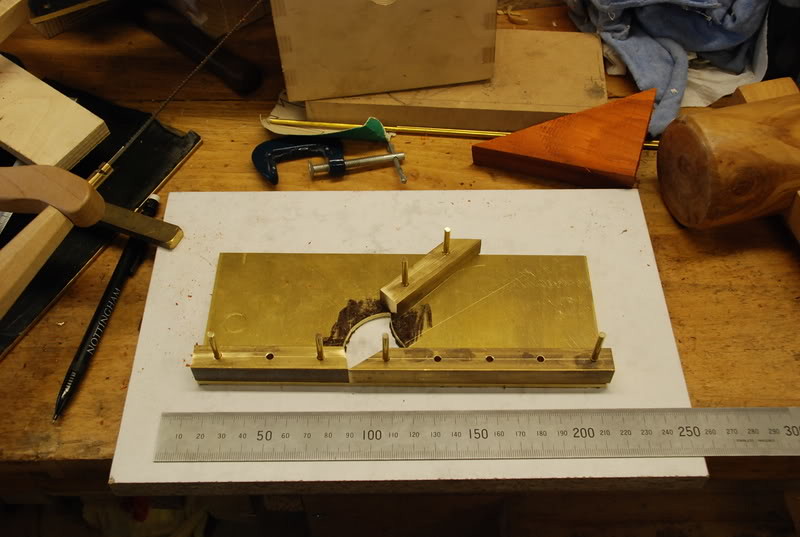

Drilled some holes

DSC_0048 by pete maddex, on Flickr

DSC_0048 by pete maddex, on Flickr

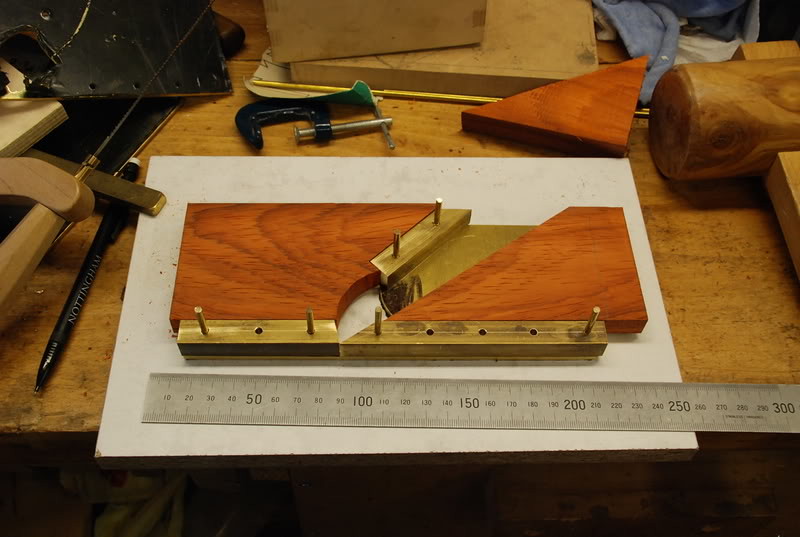

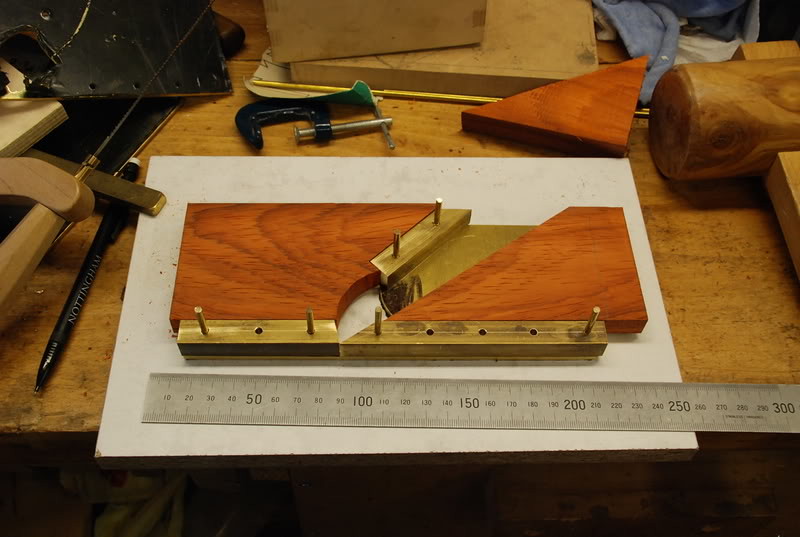

Cut some Padouk.

DSC_0049 by pete maddex, on Flickr

DSC_0049 by pete maddex, on Flickr

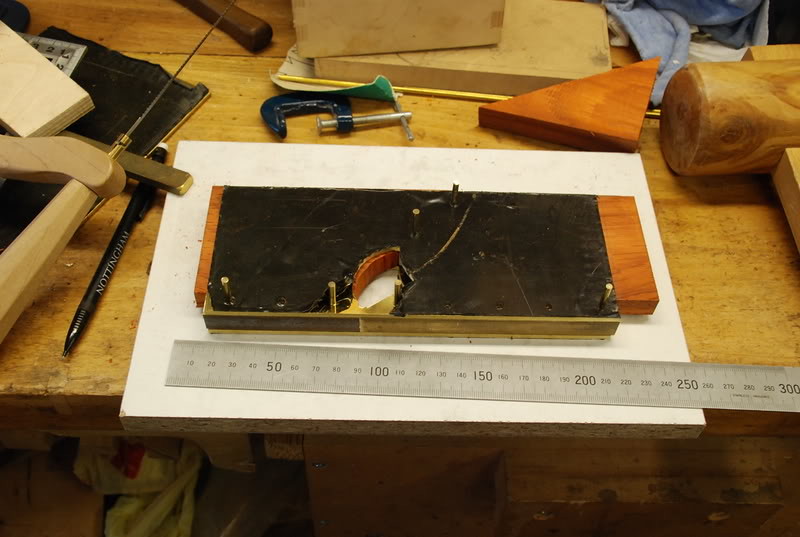

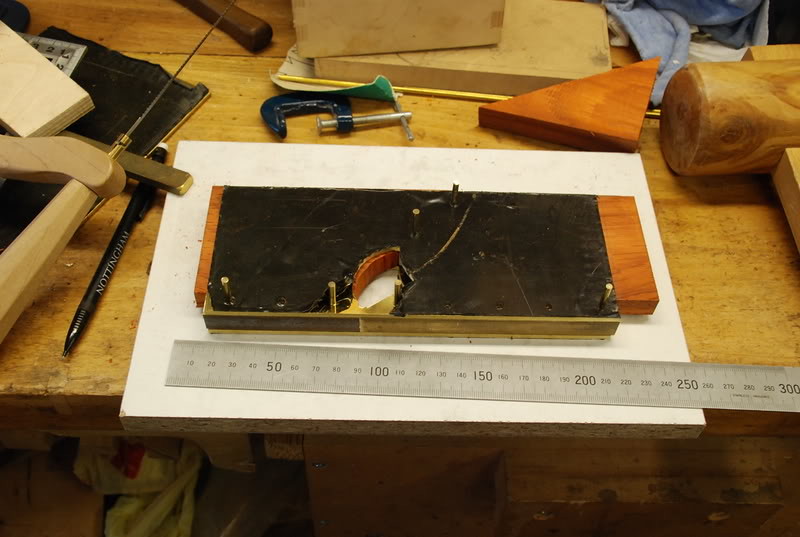

Drilled some more holes.

DSC_0051 by pete maddex, on Flickr

DSC_0051 by pete maddex, on Flickr

Fitted the bits together.

DSC_0050 by pete maddex, on Flickr

DSC_0050 by pete maddex, on Flickr

I started to do the rivets but my "mate" came over and got me cutting up his last piece of oak work top, so I will finish it in the week. I will file the mouth last once it it riveted up and I have made the blade.

Padouk makes lovely shavings.

DSC_0046 by pete maddex, on Flickr

DSC_0046 by pete maddex, on Flickr

Pete

I have loads of jobs to do, so I did something compleatly different :wink:

I cut up some 3mm and 1/2 inch square brass on my band saw with a fine blade.

DSC_0047 by pete maddex, on Flickr

DSC_0047 by pete maddex, on FlickrDrilled some holes

DSC_0048 by pete maddex, on Flickr

DSC_0048 by pete maddex, on FlickrCut some Padouk.

DSC_0049 by pete maddex, on Flickr

DSC_0049 by pete maddex, on FlickrDrilled some more holes.

DSC_0051 by pete maddex, on Flickr

DSC_0051 by pete maddex, on FlickrFitted the bits together.

DSC_0050 by pete maddex, on Flickr

DSC_0050 by pete maddex, on FlickrI started to do the rivets but my "mate" came over and got me cutting up his last piece of oak work top, so I will finish it in the week. I will file the mouth last once it it riveted up and I have made the blade.

Padouk makes lovely shavings.

DSC_0046 by pete maddex, on Flickr

DSC_0046 by pete maddex, on FlickrPete