MikeG.

Established Member

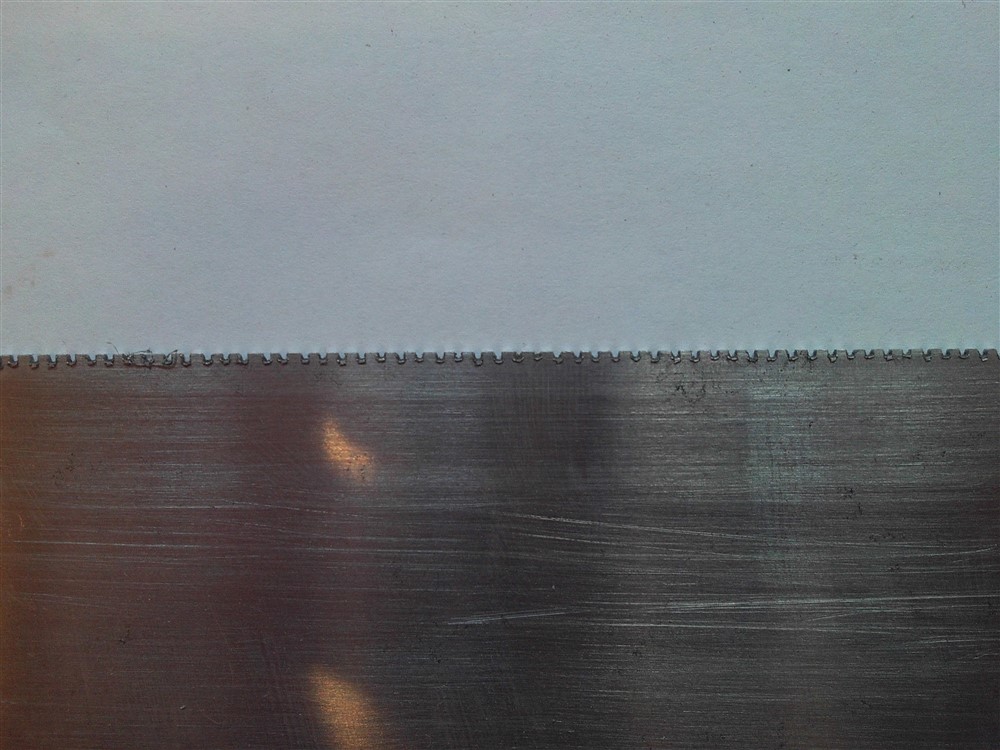

For 30 years or more this awful freebie has kicked around in the back of drawers in my workshop, unusable on wood. I can't remember whether it came free in a Cornflakes packet, or with maybe a handsaw, but it was so awful that the last time I used it was as a scraper on some rock-hard plaster to try to form a key (it was useless even at that). Here it is in all its glory:

Isn't it gorgeous?

It had some sort of coating on it which had prevented it rusting, so cleaning it up wasn't very difficult (120 grit and a squirt of WD40):

Being hardpoint (heat treated), the teeth were too hard to file off, so I marked a line and ground them off on the bench grinder:

There wasn't an awful lot of merit in the handle, so I ummed and ahhed for a while before deciding to make a new one. I just happened to have a scrap or two of bog oak kicking around, so I thought I might try that. I traced over a handle from my tenon saw which I've always found really comfortable:

I've never owned a pistol grip saw, so I thought I'd give that a try. I sketched out the bits I didn't need, and in a few minutes on the pillar drill and the bandsaw produced a blank:

It's not too late to go back to the original handle, but the saw nuts will only screw into the plastic so many times........ Anyway, a few minutes with a rounding over bit on the router (mind that end grain!), then rasps, sandpaper, bits of dowel, chisels........you know, getting rid of all the stuff I didn't want, I ended up with a really comfortable handle:

Cleaned up with some white spirit:

It'll probably need some teeth, I guess. I've never cut teeth from scratch before, and I've no idea how it is supposed to be done, so after filing the edge dead straight, I printed off some lines at 12 per inch (my other saws are 15 and 21 TPI, so I've got the finer stuff covered):

Then taped a section of it over the edge of the plate:

I transferred those lines to the plate by sawing directly through the paper with a junior hacksaw. I sawed too deep, as you'll see later:

Interestingly, I picked the plate up at this stage and without a handle, used it to cut pretty cleanly through a piece of 2x1 pine!!

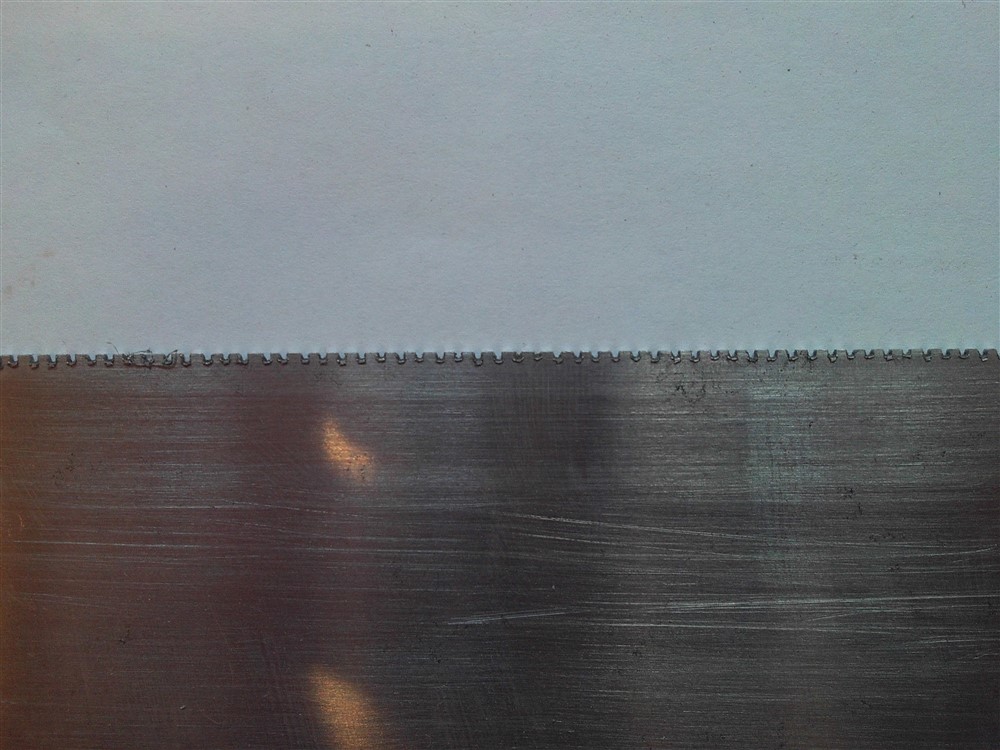

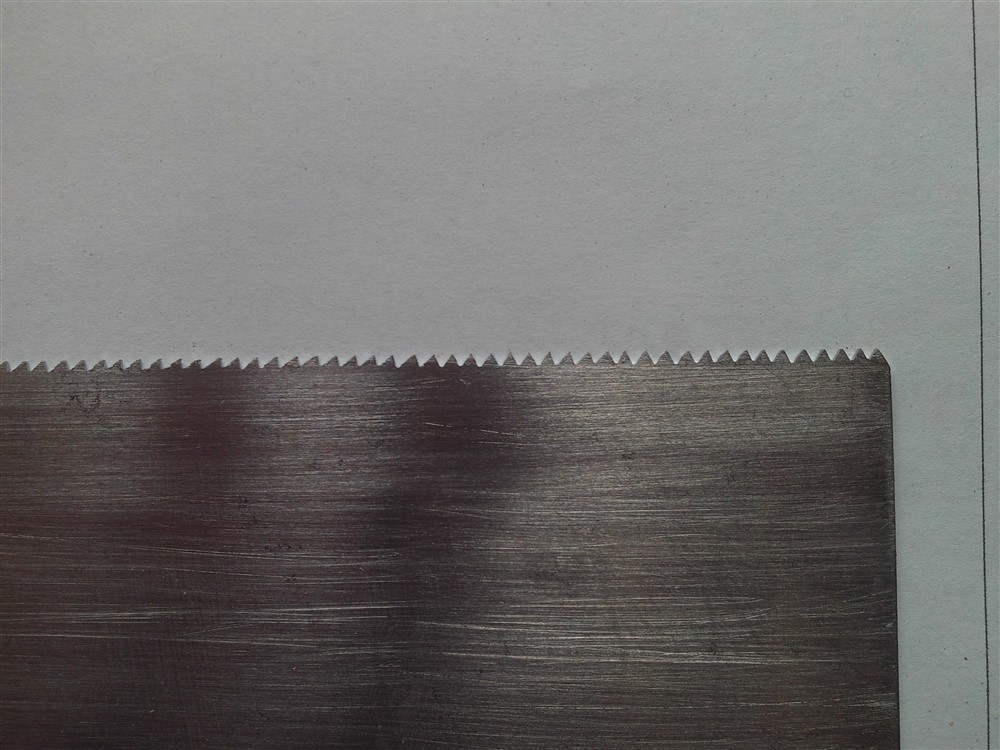

Now, I've heard one or two people talk about using a soft start to their tenon saws, going from a relaxed profile to a rip profile over the first couple of inches, so I thought I'd give that a try:

You can see the slope of the front of each tooth change from 60 degrees to vertical over the first 2 inches. You can also see that the over-deep hacksaw cuts have left their mark. This saw won't really be right on this sharpening, but I'll get it spot on next time.

My damn setting pliers snapped in half whilst setting the teeth. Cheap rubbish only lasted 40 years:

It works, even without any saw nuts:

I really like the gradation in colour in the handle, which just has a coat or 2 of Osmo on it, and some wax:

And just a reminder of what it looked like when it started:

I'll order the saw nuts on Monday, and they'll be the most expensive part of the saw.

Isn't it gorgeous?

It had some sort of coating on it which had prevented it rusting, so cleaning it up wasn't very difficult (120 grit and a squirt of WD40):

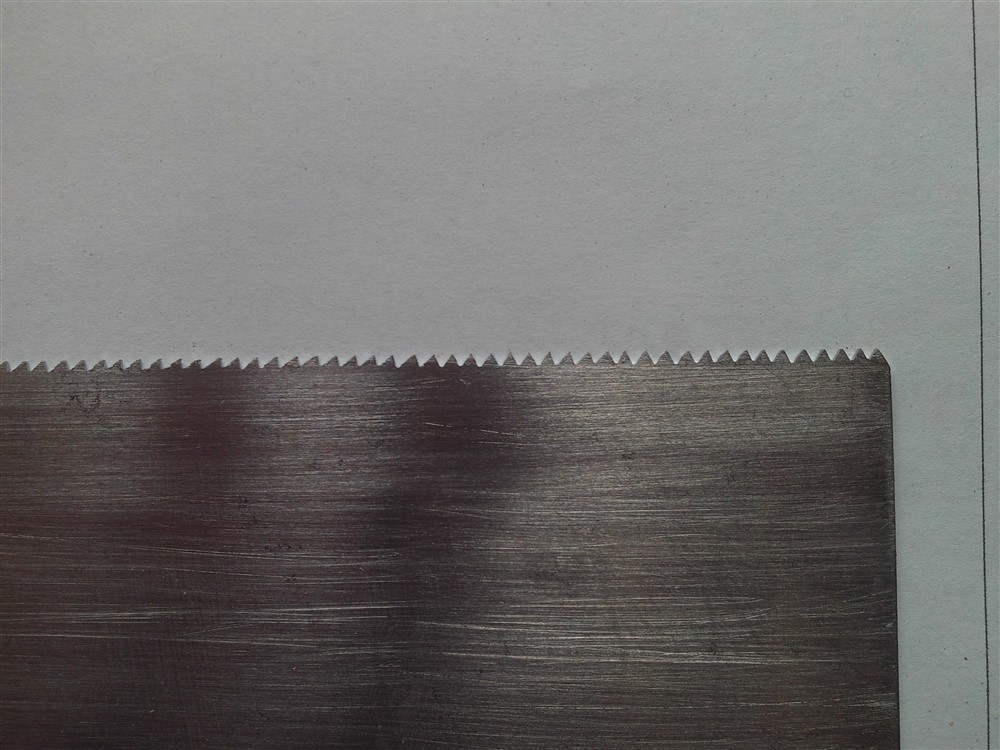

Being hardpoint (heat treated), the teeth were too hard to file off, so I marked a line and ground them off on the bench grinder:

There wasn't an awful lot of merit in the handle, so I ummed and ahhed for a while before deciding to make a new one. I just happened to have a scrap or two of bog oak kicking around, so I thought I might try that. I traced over a handle from my tenon saw which I've always found really comfortable:

I've never owned a pistol grip saw, so I thought I'd give that a try. I sketched out the bits I didn't need, and in a few minutes on the pillar drill and the bandsaw produced a blank:

It's not too late to go back to the original handle, but the saw nuts will only screw into the plastic so many times........ Anyway, a few minutes with a rounding over bit on the router (mind that end grain!), then rasps, sandpaper, bits of dowel, chisels........you know, getting rid of all the stuff I didn't want, I ended up with a really comfortable handle:

Cleaned up with some white spirit:

It'll probably need some teeth, I guess. I've never cut teeth from scratch before, and I've no idea how it is supposed to be done, so after filing the edge dead straight, I printed off some lines at 12 per inch (my other saws are 15 and 21 TPI, so I've got the finer stuff covered):

Then taped a section of it over the edge of the plate:

I transferred those lines to the plate by sawing directly through the paper with a junior hacksaw. I sawed too deep, as you'll see later:

Interestingly, I picked the plate up at this stage and without a handle, used it to cut pretty cleanly through a piece of 2x1 pine!!

Now, I've heard one or two people talk about using a soft start to their tenon saws, going from a relaxed profile to a rip profile over the first couple of inches, so I thought I'd give that a try:

You can see the slope of the front of each tooth change from 60 degrees to vertical over the first 2 inches. You can also see that the over-deep hacksaw cuts have left their mark. This saw won't really be right on this sharpening, but I'll get it spot on next time.

My damn setting pliers snapped in half whilst setting the teeth. Cheap rubbish only lasted 40 years:

It works, even without any saw nuts:

I really like the gradation in colour in the handle, which just has a coat or 2 of Osmo on it, and some wax:

And just a reminder of what it looked like when it started:

I'll order the saw nuts on Monday, and they'll be the most expensive part of the saw.