adzeman

Established Member

One of the things that tends to frustrate and annoy me is when you go to a shop to purchase an item you have bought many times before only to find its no longer manufactured.

This occurred recently when I completed my garden security gate and needed to gaze its observation window. The plan was to insert a Bulls Eye pane of glass only to be informed by my local glazier these are no longer available and had to reluctantly settle for plain glass. I decided that the next time I went home (where I originate from) I would enquire there.

It was confirmed that this type of glazing is no longer manufactured not even by the Chinese, who are supposed to make everything. But he did have a number of second hand ones in stock which he let me have for free. He offered to cut it for me but I could not remember the size and any way the opening I had made was a bit small for a Bulls Eye as to fit would have meant cutting into the actual Bulls Eye.

So the first job on returning home was to enlarge the opening and manufacture a frame. The sill and head were out of 95 x 20 mm softwood and the stiles from 70 x 20 mm.

As this was a small quantity of stock only 250mm long machining a 500 long length was not practical so I used one of my wooden plough planes to make the rebates and grooves.

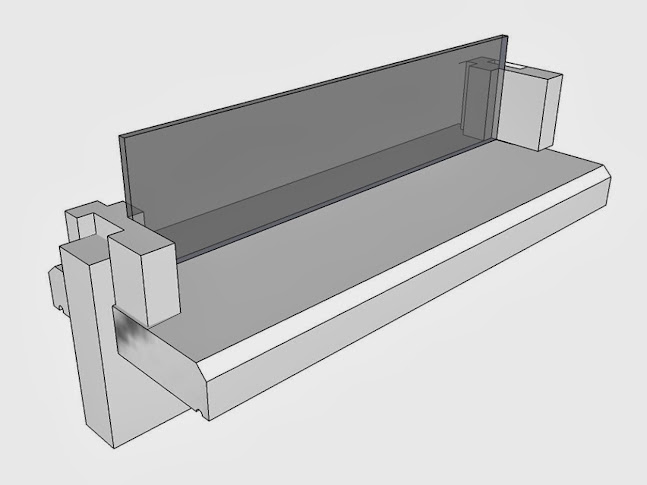

The plan

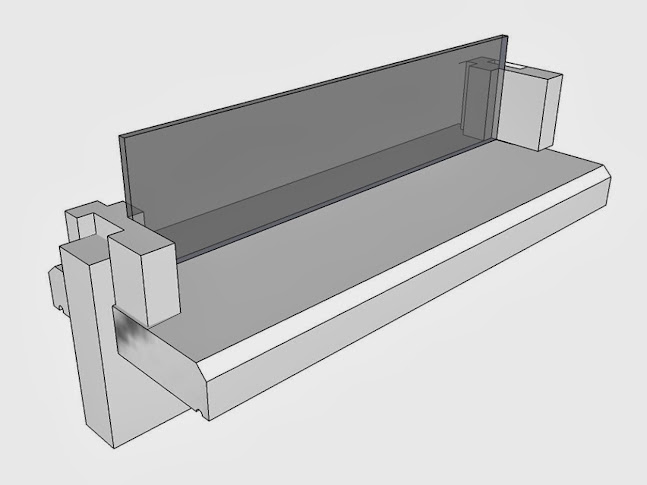

The end result

The rains have been coming down putting a halt to applying a protective stain but at the first dry spell will finish the job.

This occurred recently when I completed my garden security gate and needed to gaze its observation window. The plan was to insert a Bulls Eye pane of glass only to be informed by my local glazier these are no longer available and had to reluctantly settle for plain glass. I decided that the next time I went home (where I originate from) I would enquire there.

It was confirmed that this type of glazing is no longer manufactured not even by the Chinese, who are supposed to make everything. But he did have a number of second hand ones in stock which he let me have for free. He offered to cut it for me but I could not remember the size and any way the opening I had made was a bit small for a Bulls Eye as to fit would have meant cutting into the actual Bulls Eye.

So the first job on returning home was to enlarge the opening and manufacture a frame. The sill and head were out of 95 x 20 mm softwood and the stiles from 70 x 20 mm.

As this was a small quantity of stock only 250mm long machining a 500 long length was not practical so I used one of my wooden plough planes to make the rebates and grooves.

The plan

The end result

The rains have been coming down putting a halt to applying a protective stain but at the first dry spell will finish the job.