Ateallthepies

Established Member

Someone asked to see some of the mods I did to my table saw so I have finally taken some pictures.

To start with I binned the original blade and bought a Freud 220mm LP30M 020. This is a larger blade so the riving knife needs trimming and also some of the square shims/washers that hold it on. Apart from this there is plenty of clearance.

I also bought some 3mm aluminium and made a zero clearance plate. I also screwed a plate underneath on the left hand side so as to give the plate something to rest on on that side.

Doing this has given me 66mm of depth versus 55mm with the original blade...

I then set about trying to improve the fence. I have the full length one on mine and it did not run smooth and sort of juddered when moving.

I had a think and decided to line the underneath with 1.5mm thick PTFE sheet. I first installed a strip of wood into the underside of the fence so as to give me something to screw the PTFE to as sticking this stuff even with the correct primers is tricky with the small surface area. I bevelled the leading edges so they don't get caught in the mitre slot. I used two pieces but a single piece would have been better...

Then I lined the bit that slides on the rail with the same 1.5mm PTFE. I was after removing all metal to metal contact and it works a treat. This made the sliding action of the fence great but it still juddered when moving.

So I had a plan, getting some 8mm Delrin rod I threaded it down to 6mm and drilled two holes in the aluminium and tapped to 6mm. Cutting off the Delrin thread to about 25mm and cutting a slot in one end I screwed it in both holes and added a lock nut. When these are just snugged up to the rail they take all the play out of the fence when moving. Now it slides back and forth effortlessly with no juddering, and can be moved with one finger if that's your thing! I had to pack the left side of the bit that rests on the rail with the green shim in the pic. This was so the fence was 90 degrees to the table top. Also because the fence now sits 1.5-2mm higher, a bit of the ali fence bit that rests on the rail needed filing down so that any work piece will be not raised up that height and will sit flat to the table.

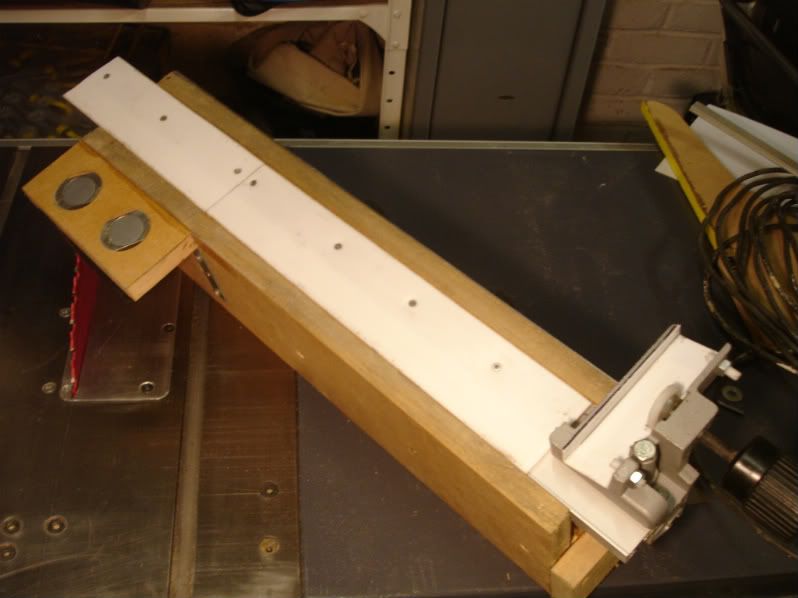

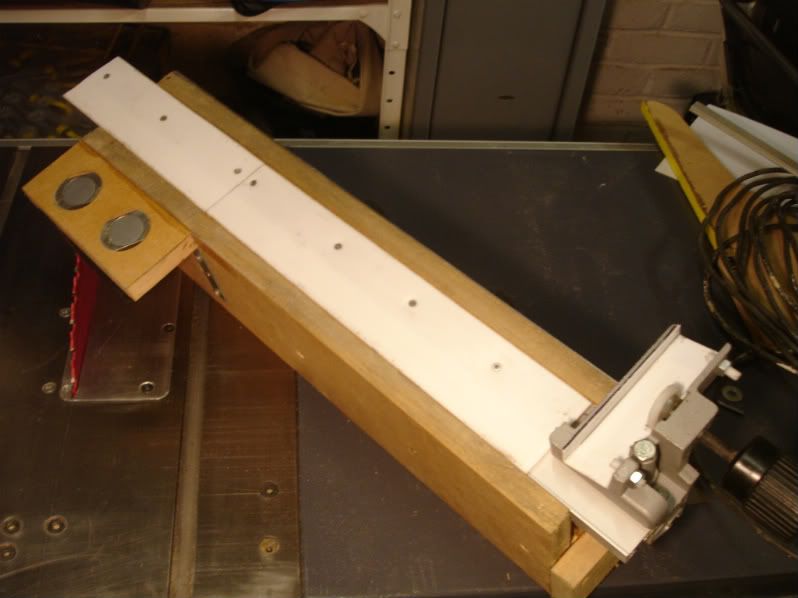

On watching Steve Maskerys vid on the sliding short fence I decided to make one only I made mine a bit longer. I did this so as to be able to use it long if I need to or slide it back to the front of the blade for a safer cut.

So a bit of 18mm MDF and lots of fiddling I made a short fence that can be locked in place with lever clamp thingies like what Steve used. I then thought that having a metal face to the fence would be nice so as to be able to use a mag-feather board. So I bought some 1.5mm mild steel strip and used double sided tape to stick this to the MDF fence. Works great and adds some nice weight to the set up.

I have a bit of play or deflection in the fence at the far end and not liking that I decided to add a couple of Mag-switches to the far end of my short fence. One would be OK but I had two so used them both and this locks the fence solid...

Other things I did was to remove all the burrs on every metal edge and on all the screw recesses, align the blade to the mitre slot to 0.10mm tolerence and jiggle the fence to match, amost. Also waxed the table and made a mall sled for cross-cutting.

Now all I gotta do is use the thing!! :lol:

Hope this is of interest to someone?

Steve.

To start with I binned the original blade and bought a Freud 220mm LP30M 020. This is a larger blade so the riving knife needs trimming and also some of the square shims/washers that hold it on. Apart from this there is plenty of clearance.

I also bought some 3mm aluminium and made a zero clearance plate. I also screwed a plate underneath on the left hand side so as to give the plate something to rest on on that side.

Doing this has given me 66mm of depth versus 55mm with the original blade...

I then set about trying to improve the fence. I have the full length one on mine and it did not run smooth and sort of juddered when moving.

I had a think and decided to line the underneath with 1.5mm thick PTFE sheet. I first installed a strip of wood into the underside of the fence so as to give me something to screw the PTFE to as sticking this stuff even with the correct primers is tricky with the small surface area. I bevelled the leading edges so they don't get caught in the mitre slot. I used two pieces but a single piece would have been better...

Then I lined the bit that slides on the rail with the same 1.5mm PTFE. I was after removing all metal to metal contact and it works a treat. This made the sliding action of the fence great but it still juddered when moving.

So I had a plan, getting some 8mm Delrin rod I threaded it down to 6mm and drilled two holes in the aluminium and tapped to 6mm. Cutting off the Delrin thread to about 25mm and cutting a slot in one end I screwed it in both holes and added a lock nut. When these are just snugged up to the rail they take all the play out of the fence when moving. Now it slides back and forth effortlessly with no juddering, and can be moved with one finger if that's your thing! I had to pack the left side of the bit that rests on the rail with the green shim in the pic. This was so the fence was 90 degrees to the table top. Also because the fence now sits 1.5-2mm higher, a bit of the ali fence bit that rests on the rail needed filing down so that any work piece will be not raised up that height and will sit flat to the table.

On watching Steve Maskerys vid on the sliding short fence I decided to make one only I made mine a bit longer. I did this so as to be able to use it long if I need to or slide it back to the front of the blade for a safer cut.

So a bit of 18mm MDF and lots of fiddling I made a short fence that can be locked in place with lever clamp thingies like what Steve used. I then thought that having a metal face to the fence would be nice so as to be able to use a mag-feather board. So I bought some 1.5mm mild steel strip and used double sided tape to stick this to the MDF fence. Works great and adds some nice weight to the set up.

I have a bit of play or deflection in the fence at the far end and not liking that I decided to add a couple of Mag-switches to the far end of my short fence. One would be OK but I had two so used them both and this locks the fence solid...

Other things I did was to remove all the burrs on every metal edge and on all the screw recesses, align the blade to the mitre slot to 0.10mm tolerence and jiggle the fence to match, amost. Also waxed the table and made a mall sled for cross-cutting.

Now all I gotta do is use the thing!! :lol:

Hope this is of interest to someone?

Steve.