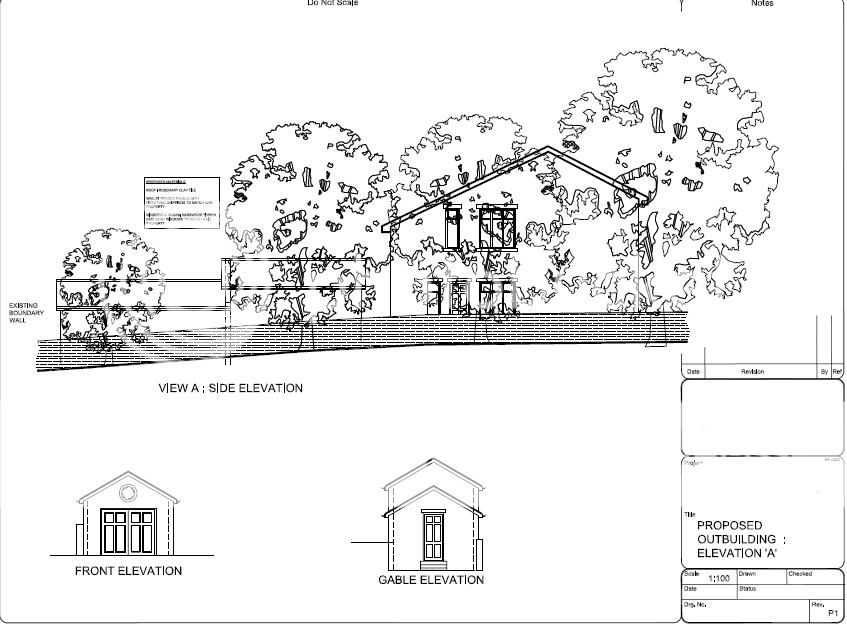

Update - got my planning permission - just shy of the 8 weeks quoted by the planning department and the Management Agents (for next door) came back with acceptable conditions in relation to the dig, and confirmed that the Church Commisoners are happy to give their consent.

It turned out that the wall is actually mine, as confirmed by an extract from the original deeds - circa 1918. But I suppose it's a case of trading some rights for others - i.e. giving next door some say over it's appearance and consulting them, in return for them easing the restrictive covenant on the strip of land on which the workshop\garage is being built.

Had 2 chap in to quote for the groundworks - he seemed interested but never got back to me. The other chap who had been before - quoted a reasonable price, so I asked him back round in the first several days of June - just to go over stuff and make sure there was no mis-understanding.

When asked,

1. There are 2 buildings?

2. Are you sure you want a Building Regs certificate?

The TV programmes I watch - when they are on - are either Norm (workshop or This Old House) or Holmes on Homes, and as Mike Holmes says "If they say you don't need a permit, walk away."

When this chap started suggesting doing this without involving Building Regs and ignoring the Structural Engineers advice - I thought "no thanks".

That left me stuck thinking WTF now? And the plan had been to break ground on the 1st weekend of June, now 2-3 days away.

Well Ebay came to the rescue, On Sat eve, the following turned up,

Cost £50 for the day & £20 for collection & delivery - fully fuelled up and with a spare jerrycan.

There was a path running down the garden which seemed to have several stone flags, so we thought we'd take them up first. We soon realised that the whole path was stone flags - something I had never realised having lived there for around 10 years - with a thin skim of concrete over the top.

You can just make out the beginning of the path at the bottom of the steps on the right of the picture. It's the darker flags - around 10 inches wide. Awesome find - will be putting them back at the end for the new path.

A friend came round professing to have driven one a fair bit, so we fired it up and got some topsoil removed in about 2 hours. What made me somewhat unhappy was the number of times he struck the drystone wall with the bucket,

That's a picture before any work started - but you can see the wall. I realised due to some eye condition he has - keratoconus, his perception of depth can be poor.

So on Sunday morning at 09.30 - I never get up that early on a Sunday, I got on the digger, reasoning that having driven forklift trucks a lot in the past - it couldn't be any more difficult, so after a few hours,

And then after a few more hours later ended up with this,

The topsoil etc. removed from the dig will just be spread round the rest of the garden to level it out - it's a bit unlevel and bumpy.

That's the base for the workshop on the whole. Even though the site has been cleared to the back of the existing garage. The plan is to build the workshop first - empty out the garage first - demolish it and then build on the workshop.

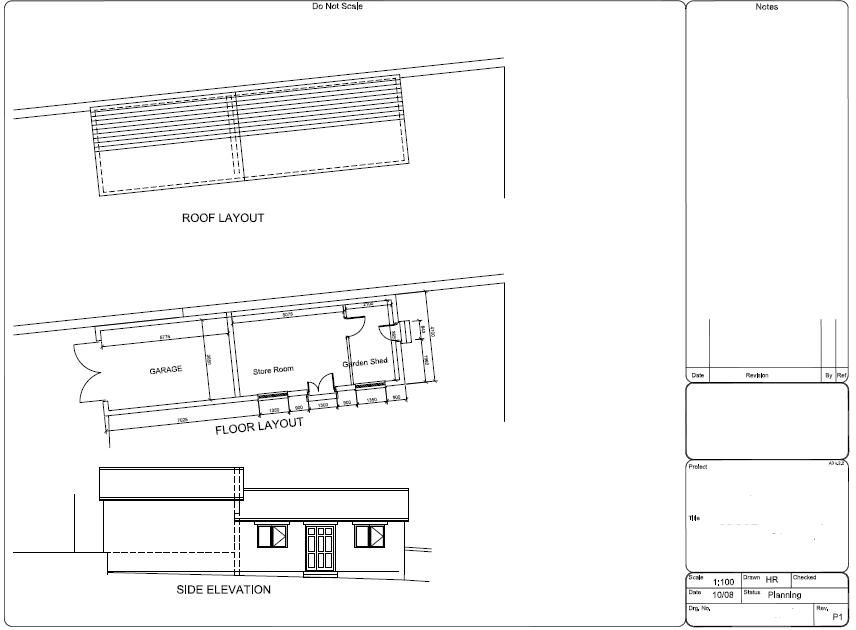

The white line marks out the approx footprint of the workshop - 7.5m long by 4m wide, and it will be adjacent to the boundary wall.

I put up a string line - to get an idea of how much of a "cut" was required to get it reasonably level - or at least minimise the "fill" at the bottom.

The digging stops short of the boundary wall - the advice from the engineer has been to do r\c slap with integrated groundbeams, the one nearest to the boundary wall to be stepped back 0.5m, with the slab cantilevered over the beam.

The next picture shows the stepped dig a bit better,

Standing on the white line, a part of which is showing in the picture above (at the bottom left) - i.e. the separating wall between the garage and workshop, and facing the back of the existing garage, shows,

shows the height of the existing garage basement\pit to be now around 6 feet. So this is making me seriously considering dropping the floor in the new garage, i.e. make the foundations lower than those of the workshop by say 2 feet - to get a full basement under the garage of say 6 to 6.5 feet. The top of the opeining at the rear of the existing basement is at head height - i.e. 6 feet high, so I am optimistic it should be manageable.

Now it's just a case of "fettling" to get things a bit more level and marking out and excavating for the groundbeams. Will try it by hand - they need to be 18 inches deep, if it seems too much like hard work - I'll get the digger back in.

The following picture shows the remainder of the garden - so SWMBO and the kids still have most of it left,

Now for some advice - the original plans had been to build it in concrete block, single skin with piers say every 2m. Now the length of the building is 7.5m long and the width is 4m and I was planning on using raised tie trusses. With stud infill between the piers and some insulation.

My engineer chum is suggesting that I build the walls by laying the blocks on their side - i.e. a wall 9 inches wide. Something about being better able to resist the forces from the trusses - I can see what he means - a wall 9 inches thick would result in a more stable building, but the question I have is that would my original construction method result in an unstable building? In the workshop I am willing to lower the truss ties so that I can clear a 8x4 sheet on a diagonal and nothing more, resulting in the thrust on the wall being less than if the tie was as high as possible.

Although this will be the scenario for the garage - I would need the trusses to be somewhat higher.

On a related note - I bought approx 3500 Rosemary roof tiles for < £400 all in, so pleased with that, considering local salvage yards were quoting me £250 per 1,000 tiles plus delivery. Plus the colour match is spot on and includes enough halfs and tile & halfs to do the job.

p.s. I've never excavated footings or done any building on this scale, so any advice would be greatly appreciated. If you see anything in the pictures that could be better, etc. the advice would be much appreciated.