CaptainCaveman

Established Member

Hello all!

New here, somebody mentioned this place over on GarageJournal so thought I'd swing on by and share my ongoing build of my garden workshop.

Basically it's a small space and I've got to fit 3 motorcycles in there and still have room to work, tricky.

Anyway, here's some pictures of the story so far...

Initial googlesketchup of feasability, size versus motorcycles, just about big enough, ish:

Actual space, photo from when I was knocking through the coal shed and outhouse into one to make a study:

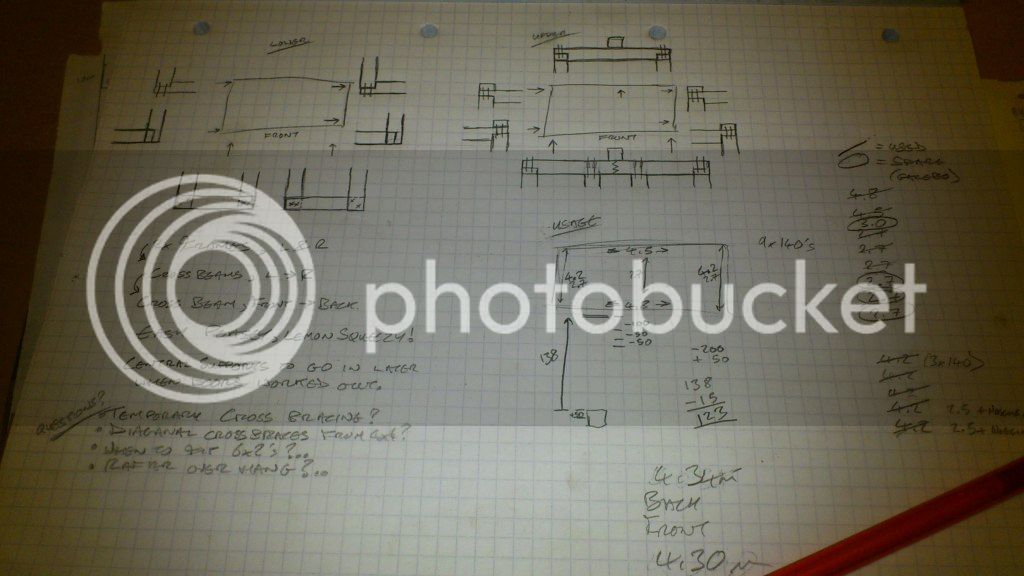

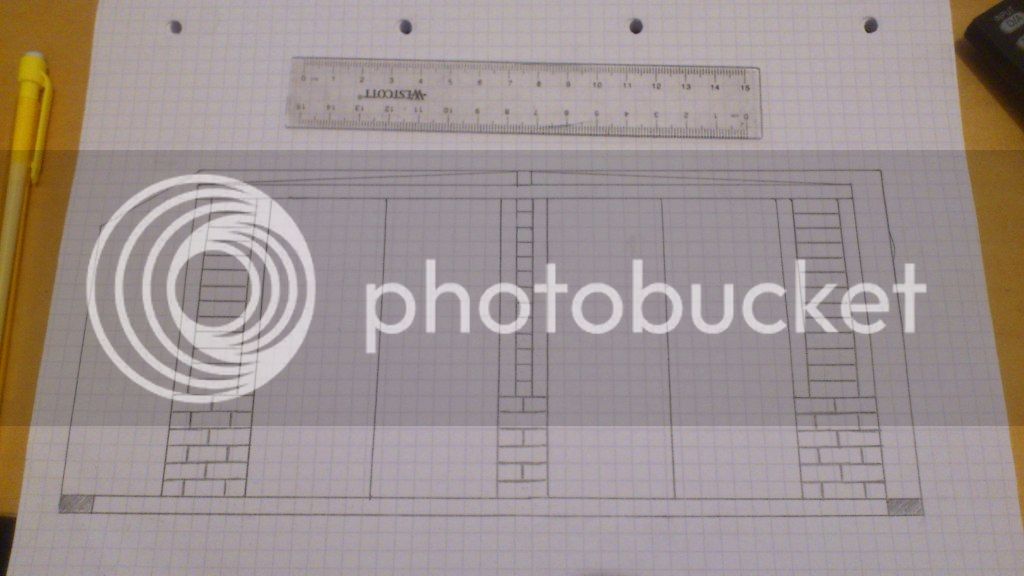

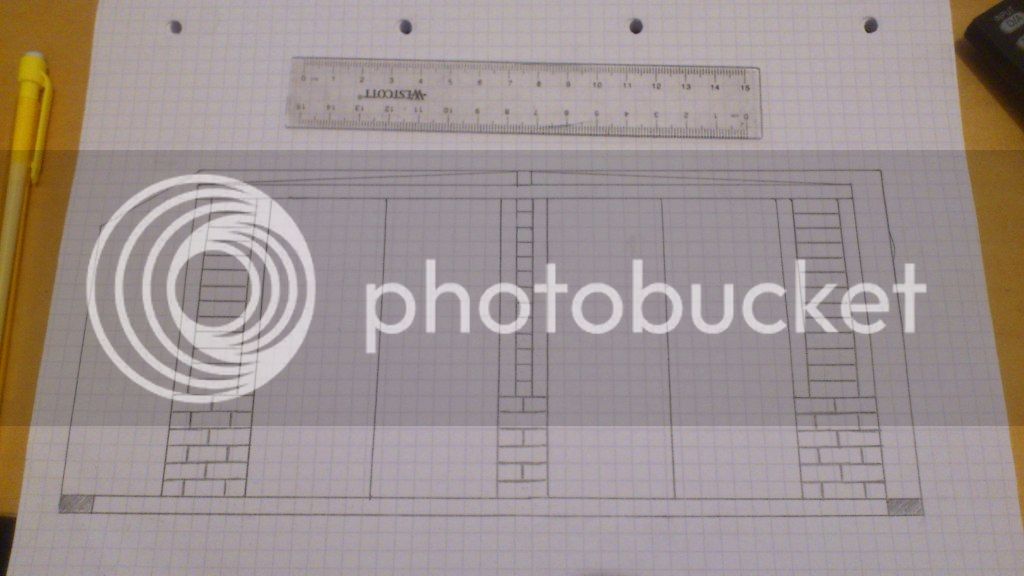

The initial plan looked something like this:

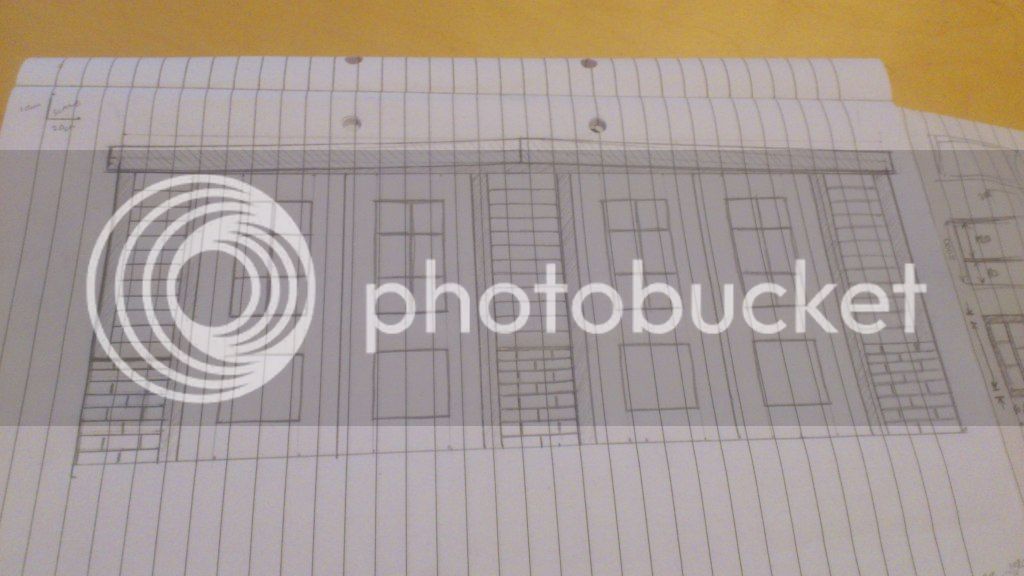

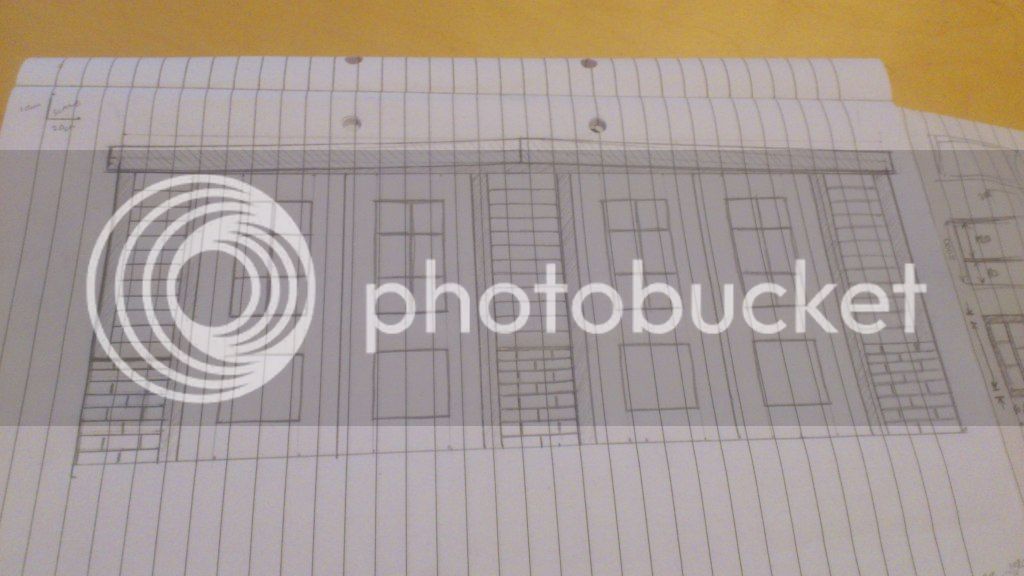

But had to be scaled down when I hacked back some ivy to reveal the profile of the wall:

Forum won't let me post pictures, I'll edit when I'm allowed...

Edit:

Victory is mine!

New here, somebody mentioned this place over on GarageJournal so thought I'd swing on by and share my ongoing build of my garden workshop.

Basically it's a small space and I've got to fit 3 motorcycles in there and still have room to work, tricky.

Anyway, here's some pictures of the story so far...

Initial googlesketchup of feasability, size versus motorcycles, just about big enough, ish:

Actual space, photo from when I was knocking through the coal shed and outhouse into one to make a study:

The initial plan looked something like this:

But had to be scaled down when I hacked back some ivy to reveal the profile of the wall:

Forum won't let me post pictures, I'll edit when I'm allowed...

Edit:

Victory is mine!