The type of mallet one prefers is a personal matter, much like one prefers a certain shape to handle for a chisel or whether one freehand sharpens or uses a honing guide.

My own preference has moved away from the round head mallets, which are best for carving. I suspect that their popularity is due to the ease with which they can be made. I have made many over the years, and even own - and enjoyed using - a Blue Spruce with the resin-infused "wood". Terrific mallet, but no longer my preference. Better suited to carvers.

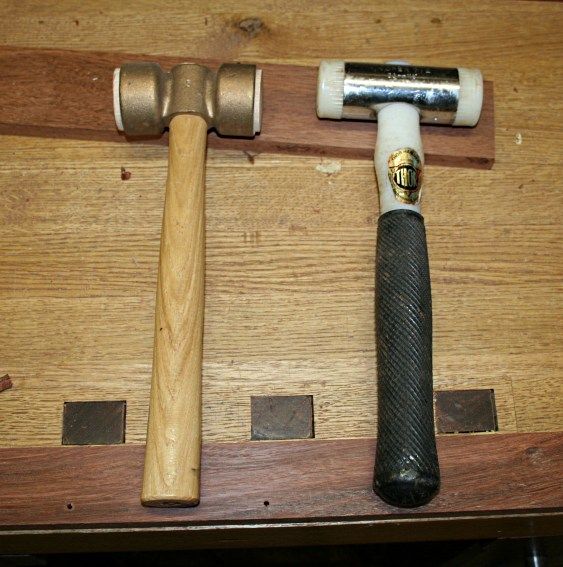

I find that a flat head channels force more directly, that one gets more power this way. The wooden-faced/brass-weighted Veritas Cabinetmakers mallet (20 oz) is excellent on non-hooped handled bench chisels, as is the Thor mallet (that Paul Sellers also uses) ...

These are too light for for morticing chisels into hard wood. So for this I built a super-heavy (36oz) mallet (by inlaying brass) ..

The reason for posting the last mallet is that a recent experience really brought home to me the value of the flat head, and indeed how important directed force is. I was testing some mortice chisels designs a few weeks back, and in particular the handles. Since they needed to be pushed to the max, I chose to sack them with a 450 gm gennou (that's just under 16 oz). Well this hammer just powered the mortice chisels beyond what I experience from the 36oz mortice mallet ... began to dent the unhooped handles somewhat, but that is by-the-by. The point is, a small hammer head with reasonable mass will outperform a heavier hammer that spreads the energy. Stay away from round mallets for bench chisels. The Japanese obviously understood this.

Above: Blue Spruce at rear, and the 450gm gennou in the centre.

Regards from Perth

Derek