sploo

Somewhat extinguished member

I saw Dennis Edwards' square edged bowl video (https://www.youtube.com/watch?v=76CcpwJR5x4) and thought I'd have a go with some pine scrap.

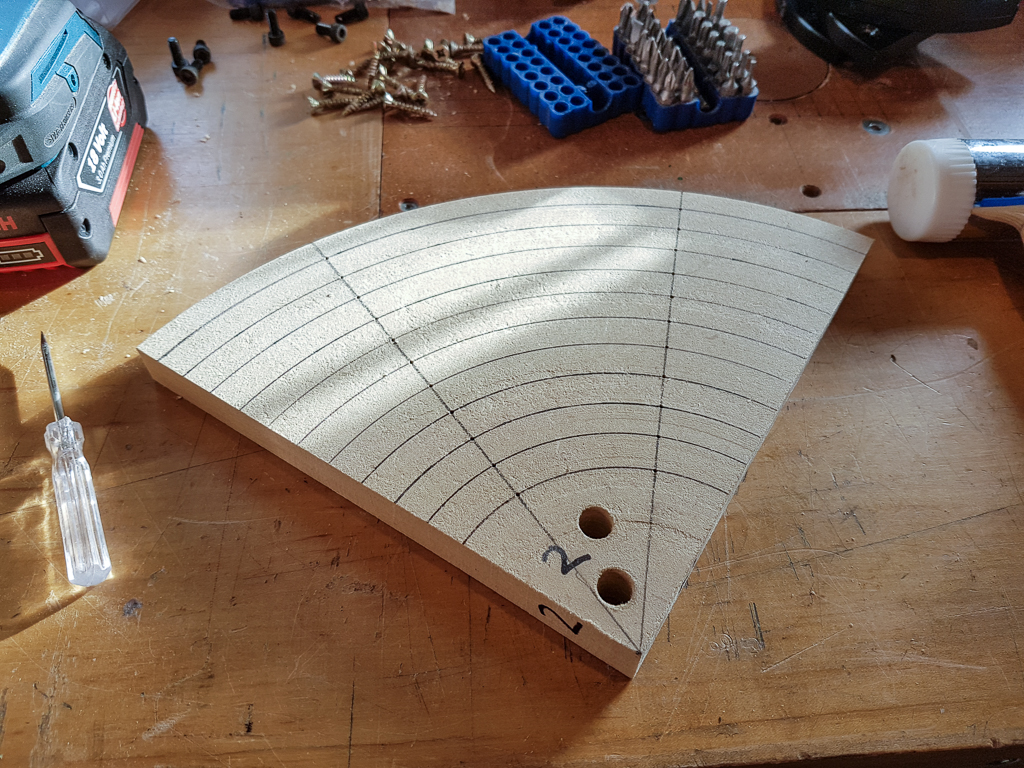

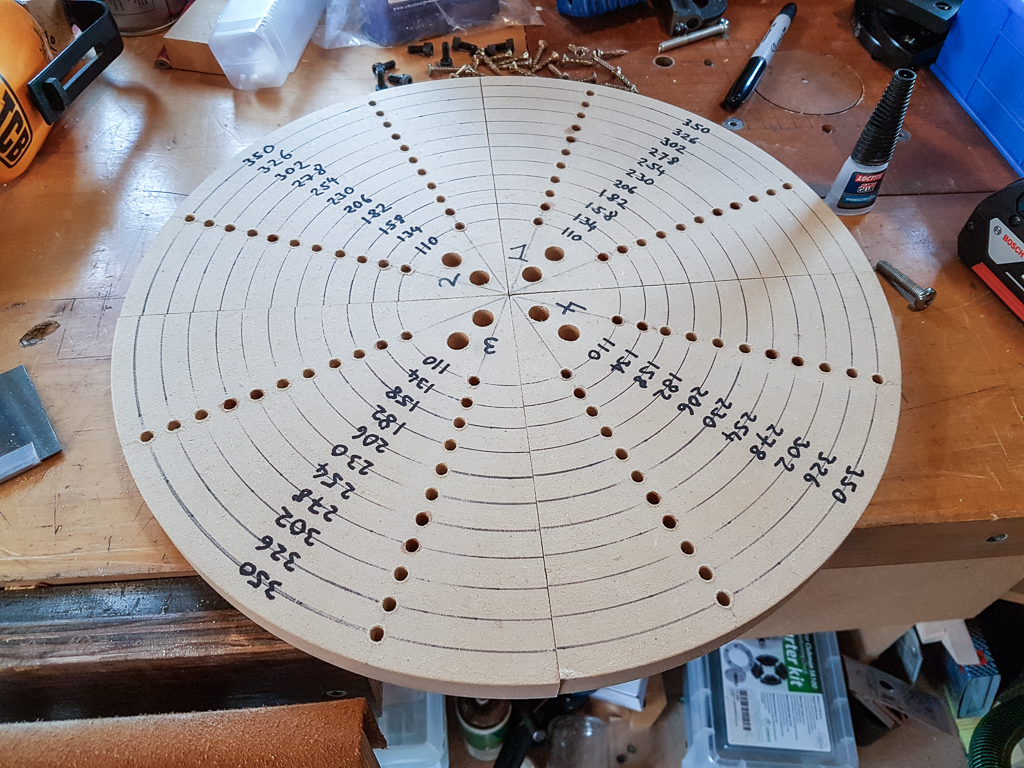

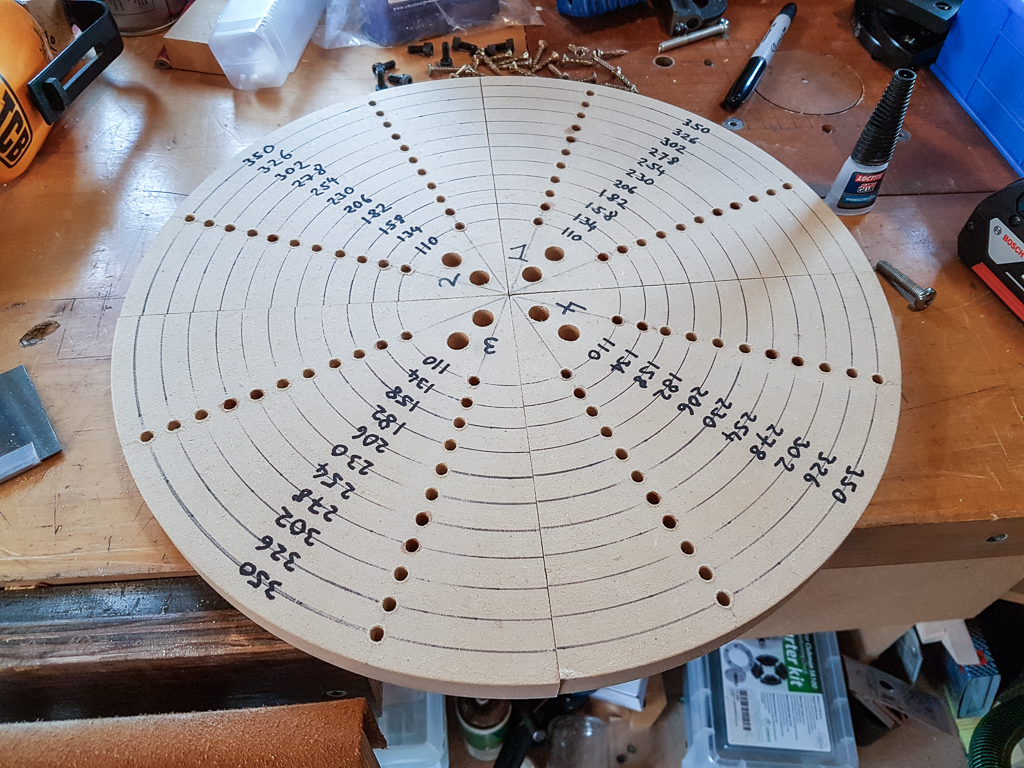

The two halves of the stock below (A and B) are separate; the idea being that you cut the 1/2 circle arcs at 45 degrees, usually on the bandsaw:

For various reasons I instead decided to use my jigsaw. Not a great idea, as a jigsaw is to fine woodworking as a rusty penknife is to heart surgery.

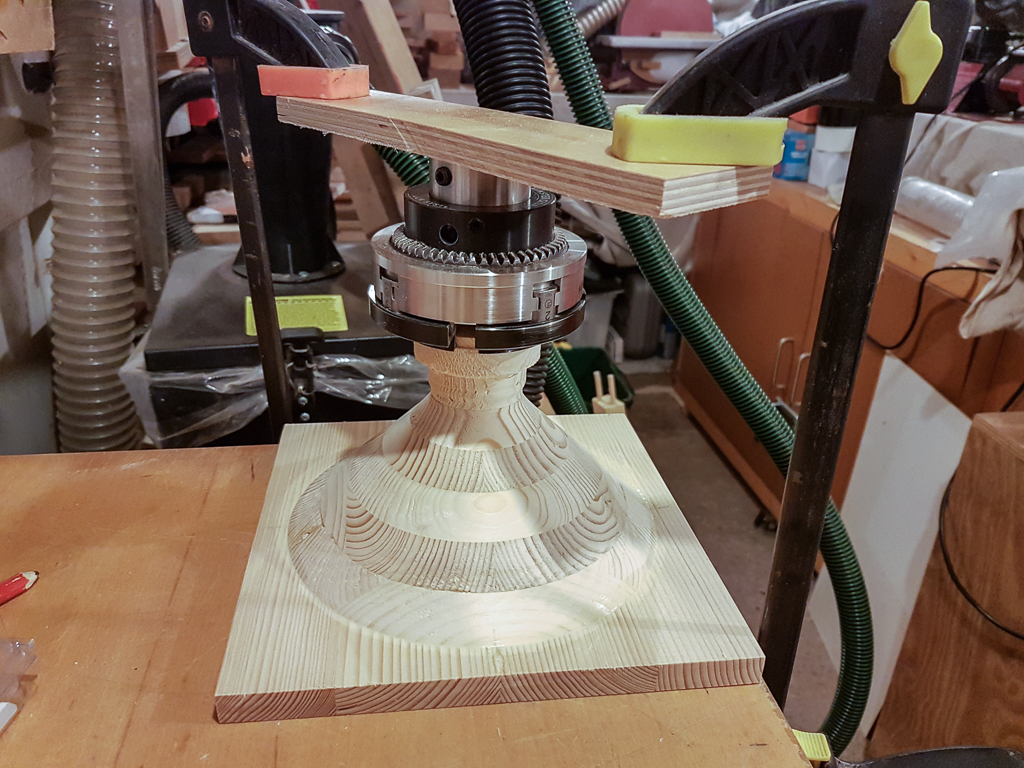

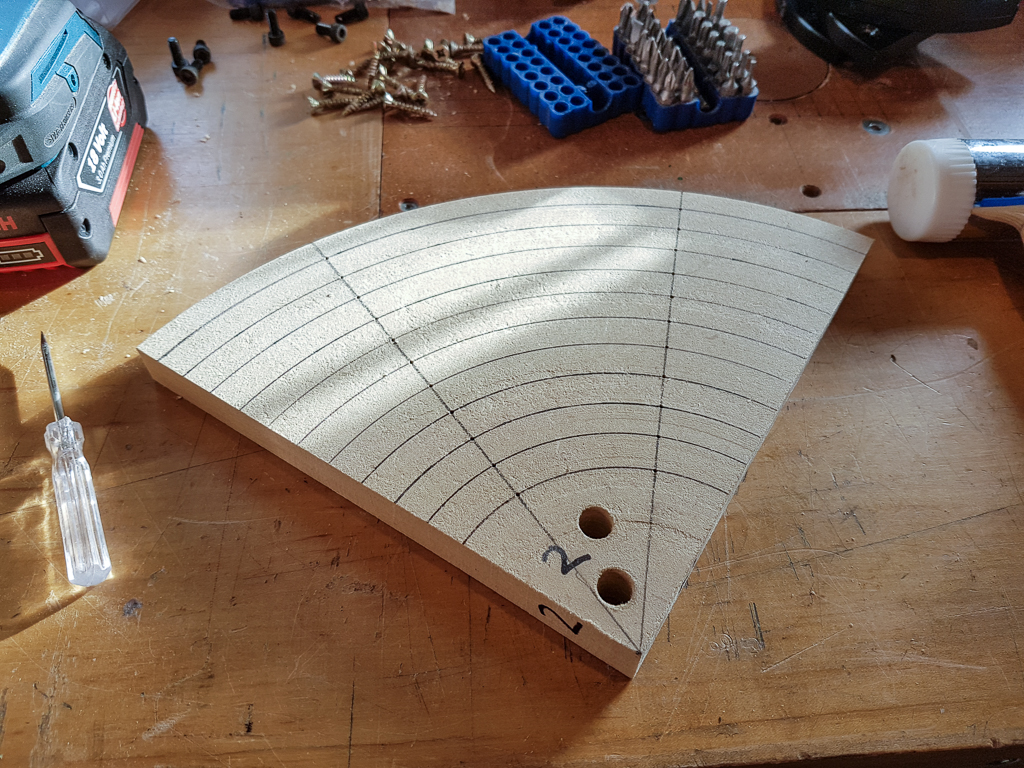

The main problems are that the ring widths need to be the same size as the stock thickness. My stock was only 15mm thick, you lose the width of the blade kerf, and the wandering of the jigsaw meant inaccuracies in the cut. You can see how far "off" the rings are:

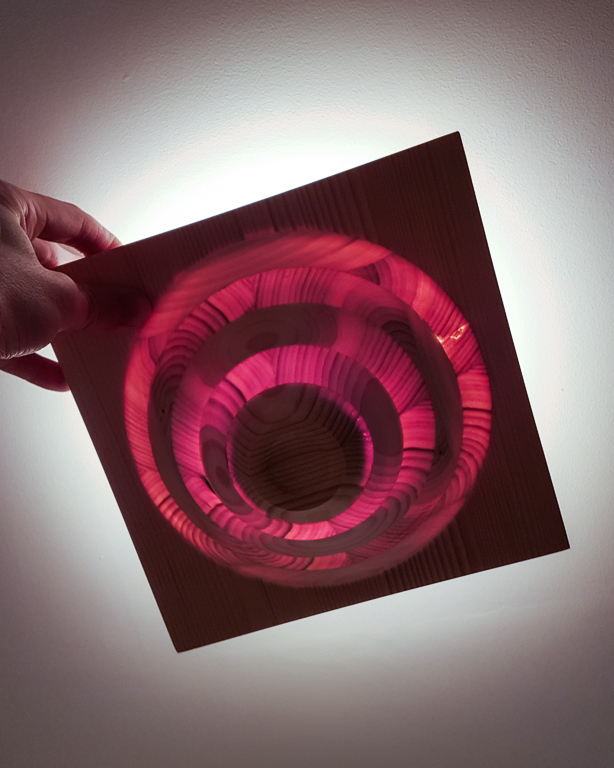

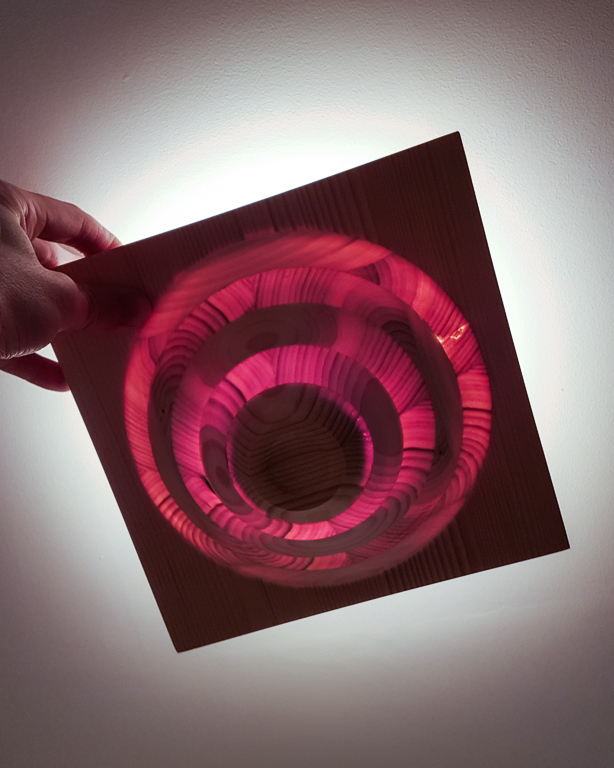

Because of those problems I knew I'd need to remove a lot of material to get the rings smooth - meaning the risk of really thin walls. Somehow it all held together (despite a lot of grain tearing). The red hue on the second image is the light bleeding through!

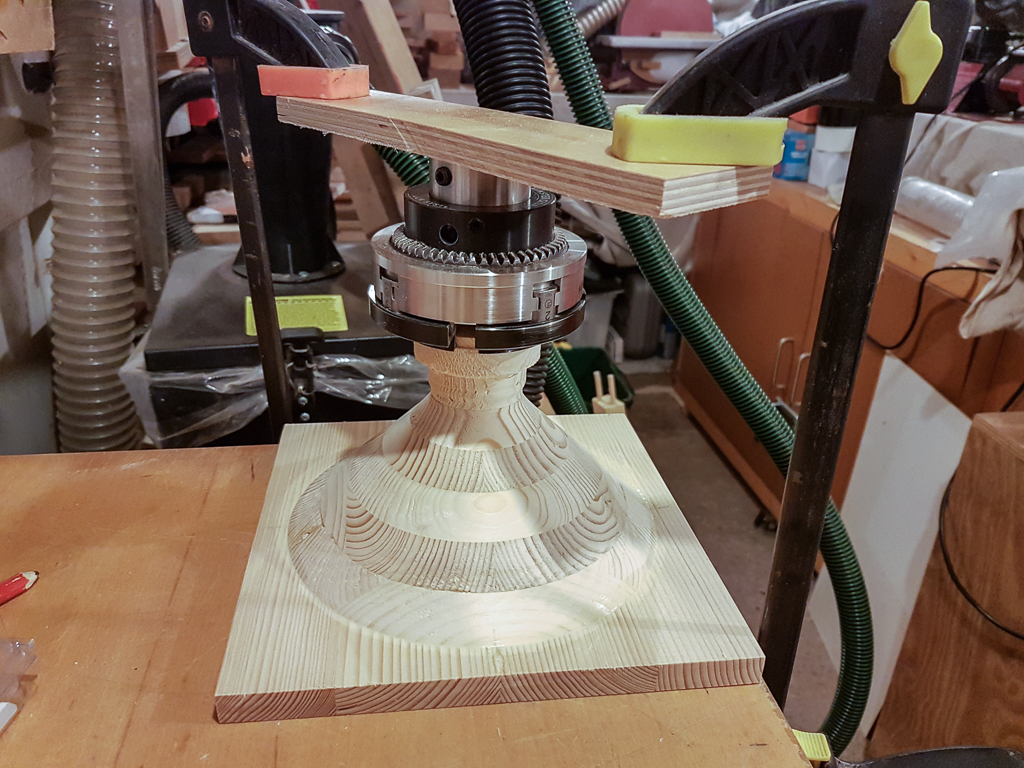

Despite all that, the end result wasn't bad, so I probably should have stopped there - but the idea was to try the square top, so on it went:

Somehow, it all stayed together; albeit the inside surface isn't remotely a flat 45 degree slope. I couldn't risk removing any more material:

Roughly cut off from the waste block to which it was glued, it's... interesting I guess:

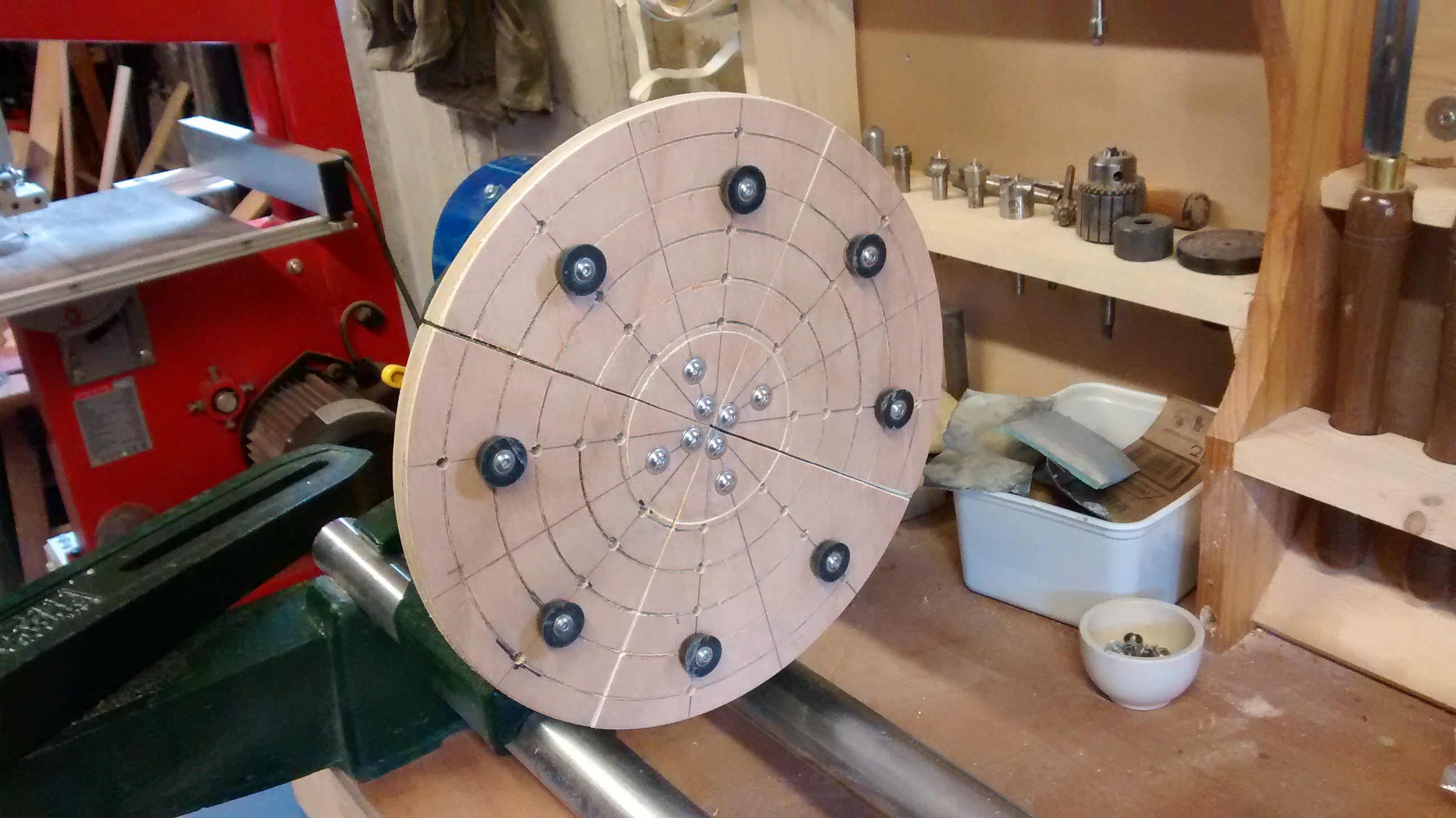

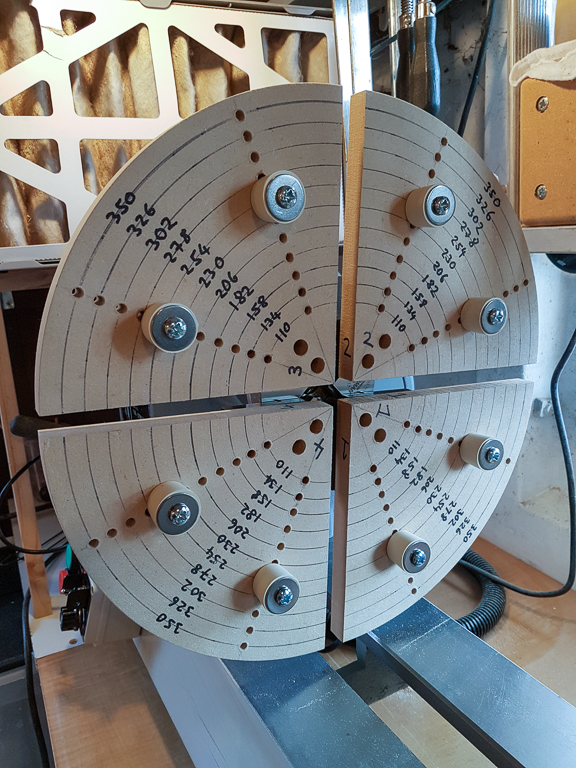

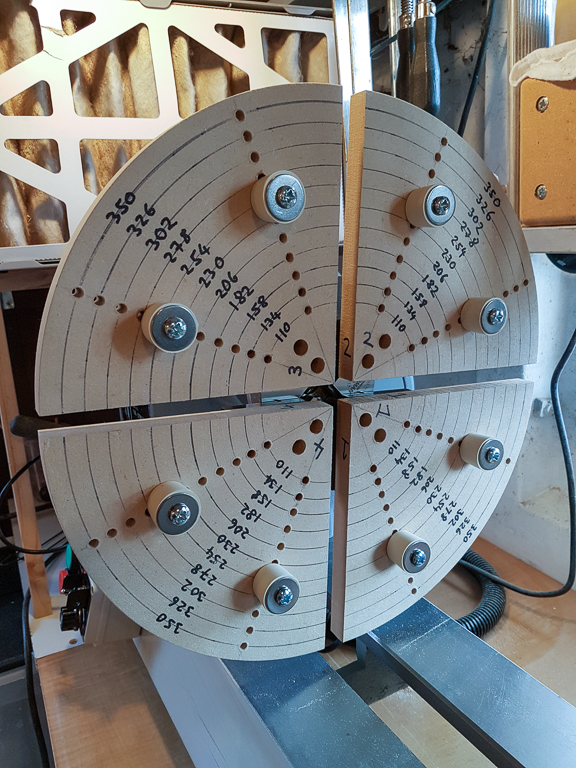

To clean up the foot I decided it was time to make some cole jaws. I used 6mm bolts in the rubber door stops, and tapped each (5mm drilled) hole in the MDF. I stabilised the threads with superglue. The plates themselves have Axminster's wood jaw plates (http://www.axminster.co.uk/150mm-wood-jaw-plates-910405) screwed on. Bonus marks for spotting the subtle error in the last image:

It seemed to hold the bowl pretty well:

How thin? Thin:

The two halves of the stock below (A and B) are separate; the idea being that you cut the 1/2 circle arcs at 45 degrees, usually on the bandsaw:

For various reasons I instead decided to use my jigsaw. Not a great idea, as a jigsaw is to fine woodworking as a rusty penknife is to heart surgery.

The main problems are that the ring widths need to be the same size as the stock thickness. My stock was only 15mm thick, you lose the width of the blade kerf, and the wandering of the jigsaw meant inaccuracies in the cut. You can see how far "off" the rings are:

Because of those problems I knew I'd need to remove a lot of material to get the rings smooth - meaning the risk of really thin walls. Somehow it all held together (despite a lot of grain tearing). The red hue on the second image is the light bleeding through!

Despite all that, the end result wasn't bad, so I probably should have stopped there - but the idea was to try the square top, so on it went:

Somehow, it all stayed together; albeit the inside surface isn't remotely a flat 45 degree slope. I couldn't risk removing any more material:

Roughly cut off from the waste block to which it was glued, it's... interesting I guess:

To clean up the foot I decided it was time to make some cole jaws. I used 6mm bolts in the rubber door stops, and tapped each (5mm drilled) hole in the MDF. I stabilised the threads with superglue. The plates themselves have Axminster's wood jaw plates (http://www.axminster.co.uk/150mm-wood-jaw-plates-910405) screwed on. Bonus marks for spotting the subtle error in the last image:

It seemed to hold the bowl pretty well:

How thin? Thin: