chippy1970

Established Member

Here's some pics of some wardrobes I built over the last week for a customer they're in two seperate rooms one with two and the other room has three wardrobes. Carcases all in 18mm mdf with shaker doors in 22mm MR/mdf with 6mm panels. For a change I didn't bother cutting up all the sheet goods myself I used Cutwrights online cutting list. I had all the mdf cut to size leaving me the job of cutting all 400+ biscuit slots and putting it all together with Spax M screws and glue. I also had all the exposed edges treated with prep tape to save the painter any hassle you may be able to see this on some of the shelves. I also had the doors made by Cut wrights which I normally do myself but for the price they did them it wasn't worth my while messing about.

All the biscuiting was done with my new toy I treated myself to a Mafell LNF20 biscuit jointer what a difference to my old Axminster one :lol:.

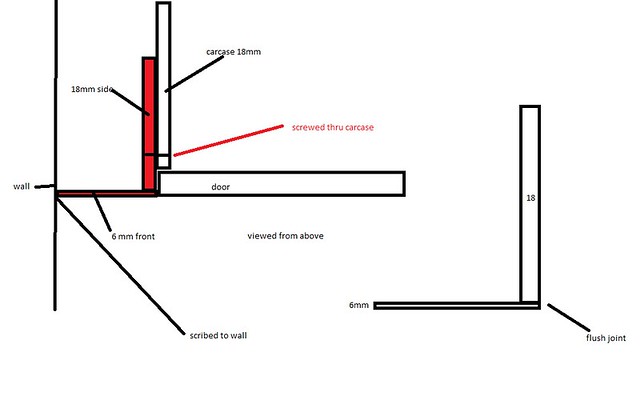

I tried out a new method of doing all my infills on this job, I decided to make up long lengths of 6mm mdf glued and pinned to 18mm to form an L shape this is then scribed and slid down the sides and tops of the carcases and screwed behind the hinge clips. This worked really well as I found that with a few notches for shelves etc I could temporarily fix these to the inside of the carcase for scribing then you can just run two bits of 18mm mdf with a pencil down the wall to mark the scribe job done. I over hung the top infill just a little to form a sort of cornice.

All the biscuiting was done with my new toy I treated myself to a Mafell LNF20 biscuit jointer what a difference to my old Axminster one :lol:.

I tried out a new method of doing all my infills on this job, I decided to make up long lengths of 6mm mdf glued and pinned to 18mm to form an L shape this is then scribed and slid down the sides and tops of the carcases and screwed behind the hinge clips. This worked really well as I found that with a few notches for shelves etc I could temporarily fix these to the inside of the carcase for scribing then you can just run two bits of 18mm mdf with a pencil down the wall to mark the scribe job done. I over hung the top infill just a little to form a sort of cornice.