adidat

I will not buy anymore tools...

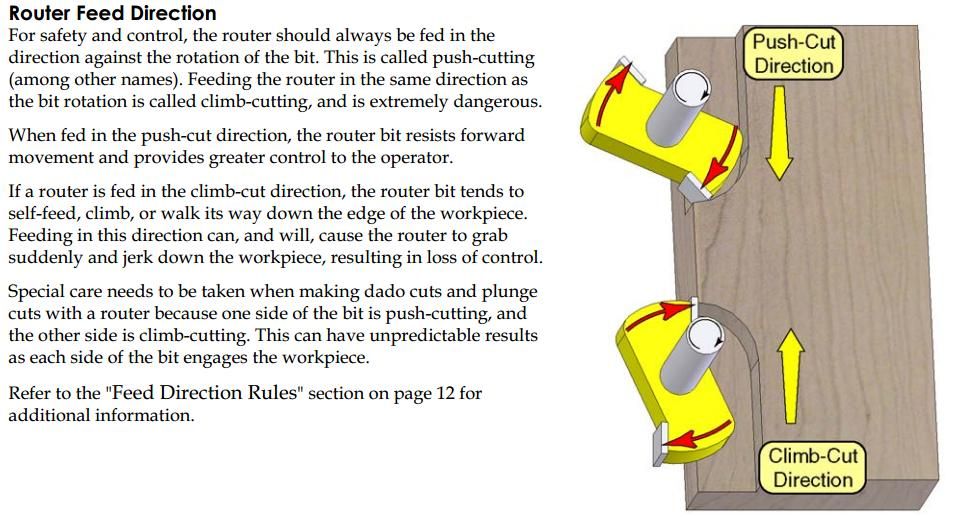

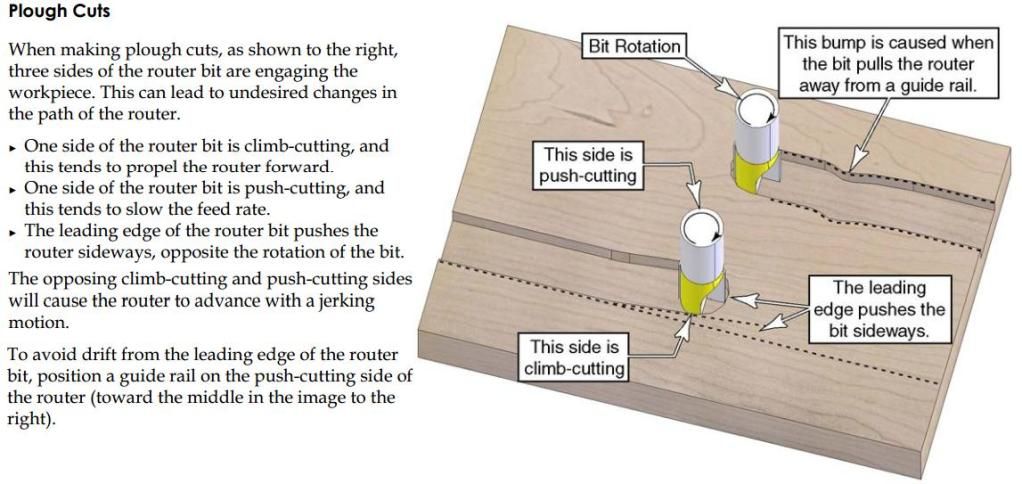

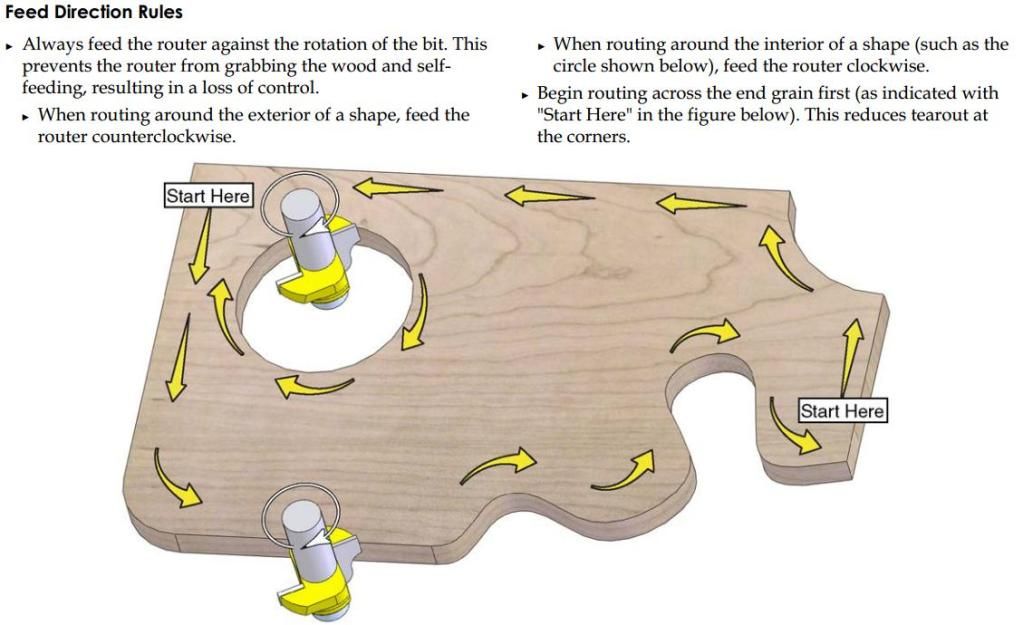

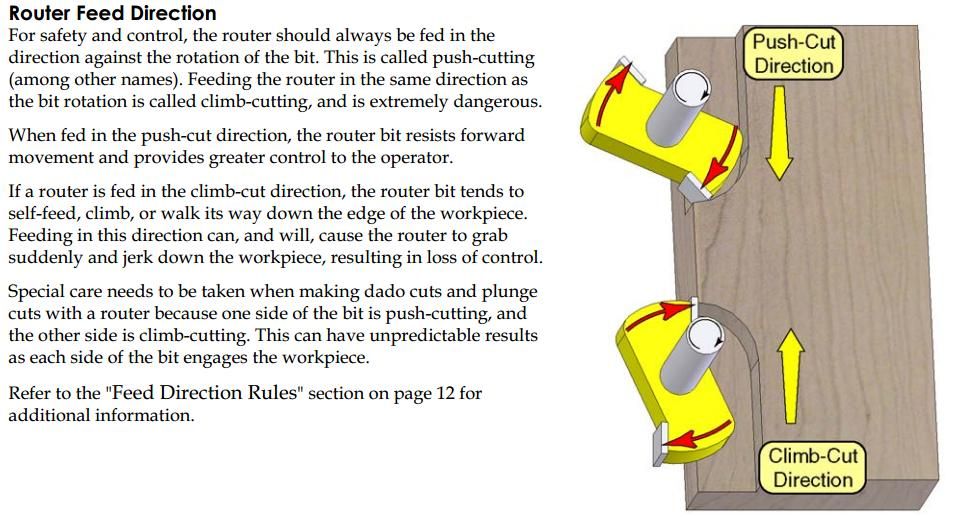

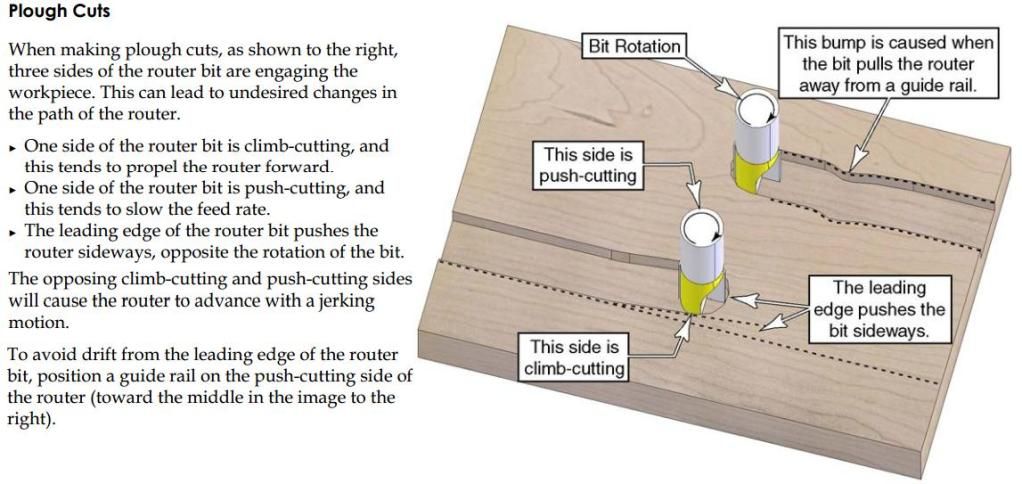

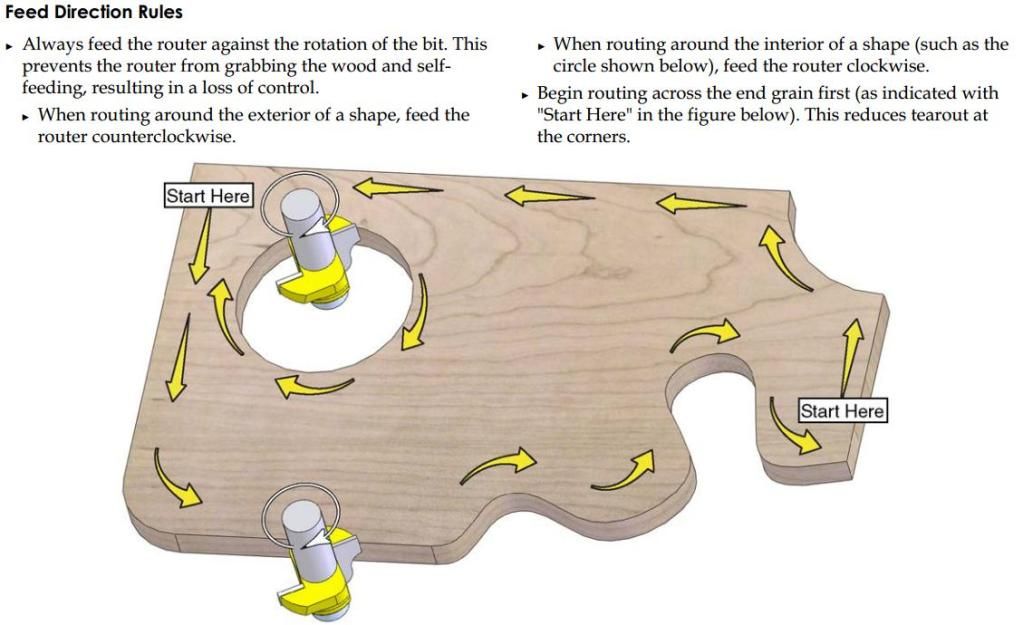

whilst looking for some Festool information i came across the manual for the 1400 router. its got some good information on the correct direction for cutting, to avoid break out poor lines. But most importantly to avoid a serious injury. so thank Festool for creating the information, I would consider posting these up in my workshop somewhere, on the inside lid of the router box maybe?

adidat

adidat